A two-stage dry mixing method for powder metallurgy iron-based mixed powder

A dry mixing and powder mixing technology, which is applied in the powder metallurgy industry, can solve the problems of irritating odor of hydrocarbon solvents, easy to block infusion pipelines, easy to corrode rubber parts, etc., so as to avoid environmental pollution and personal injury, and avoid blocking infusion Pipelines, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

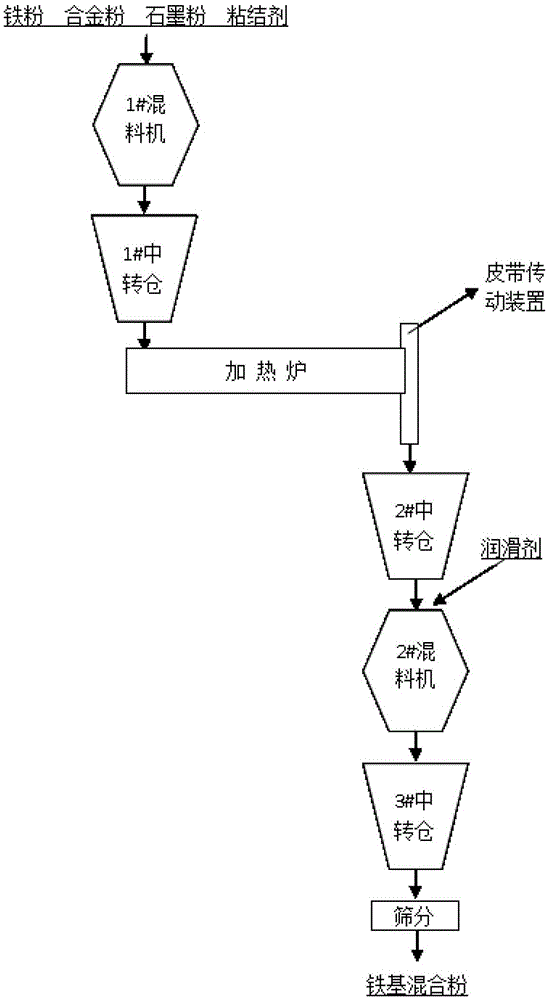

[0031] Such as figure 1 As shown, in terms of mass percentage, the production composition is Fe-2%Cu-1%Ni-0.5%C-0.6% zinc stearate iron-based mixed powder, 74 ~ 250μm ethylene polymer as binder The amount added is 0.3% of the total amount of raw materials. Add the weighed iron powder, copper powder, nickel powder, graphite powder, and binder powder into the 1# mixer and mix for 15 minutes, then put the materials in the 1# mixer into the 1# transfer bin; 1 # The material in the transfer bin is evenly spread on the steel belt of the heating furnace through the discharge port of the 1# transfer bin, with a thickness of 20mm; the temperature in the first zone of the heating furnace is 180°C, and the time for the material to pass through the first zone of the heating furnace is 6 minutes, and the material leaves the heating furnace The temperature of the steel belt is 85°C (the melting point of zinc stearate is 118°C), and it enters the 2# transfer bin with the belt conveyor; the ...

Embodiment 2

[0033] Such as figure 1 As shown, in terms of mass percentage, the production composition is Fe-2%Cu-1%Ni-0.5%C-0.6% zinc stearate iron-based mixed powder, 74 ~ 250μm ethylene polymer as binder The amount added is 0.2% of the total amount of raw materials. Add the weighed iron powder, copper powder, nickel powder, graphite powder, and binder powder into the 1# mixer and mix for 10 minutes, then put the materials in the 1# mixer into the 1# transfer bin; 1 # The material in the transfer bin is evenly spread on the steel belt of the heating furnace through the discharge port of the 1# transfer bin, with a thickness of 10mm; the temperature in the first zone of the heating furnace is 140°C, and the time for the material to pass through the first zone of the heating furnace is 2 minutes, and the material leaves the heating furnace The temperature of the steel belt is 85°C (the melting point of zinc stearate is 118°C), and it enters the 2# transfer bin with the belt conveyor; the ...

Embodiment 3

[0035] Such as figure 1 As shown, in terms of mass percentage, the production composition is Fe-2%Cu-1%Ni-0.5%C-0.6% zinc stearate iron-based mixed powder, 74 ~ 250μm ethylene polymer as binder The amount added is 0.5% of the total amount of raw materials. Add the weighed iron powder, copper powder, nickel powder, graphite powder, and binder powder into the 1# mixer and mix for 20 minutes, then put the materials in the 1# mixer into the 1# transfer bin; 1 #The material in the transfer bin is evenly spread on the steel belt of the heating furnace through the discharge port of the 1# transfer bin, with a thickness of 50mm; the temperature in the first zone of the heating furnace is 200°C, and the time for the material to pass through the first zone of the heating furnace is 10 minutes, and the material leaves the heating furnace The temperature of the steel belt is 85°C (the melting point of zinc stearate is 118°C), and it enters the 2# transfer bin with the belt conveyor; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com