Hydrolyzed marine antifouling paint and preparation method thereof

An anti-fouling paint, marine technology, applied in the field of coatings, can solve the problems of large surface roughness, easy breeding of bacteria, short anti-fouling time, etc., and achieves the effect of simple process, reduced dock repair cost, and good anti-fouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

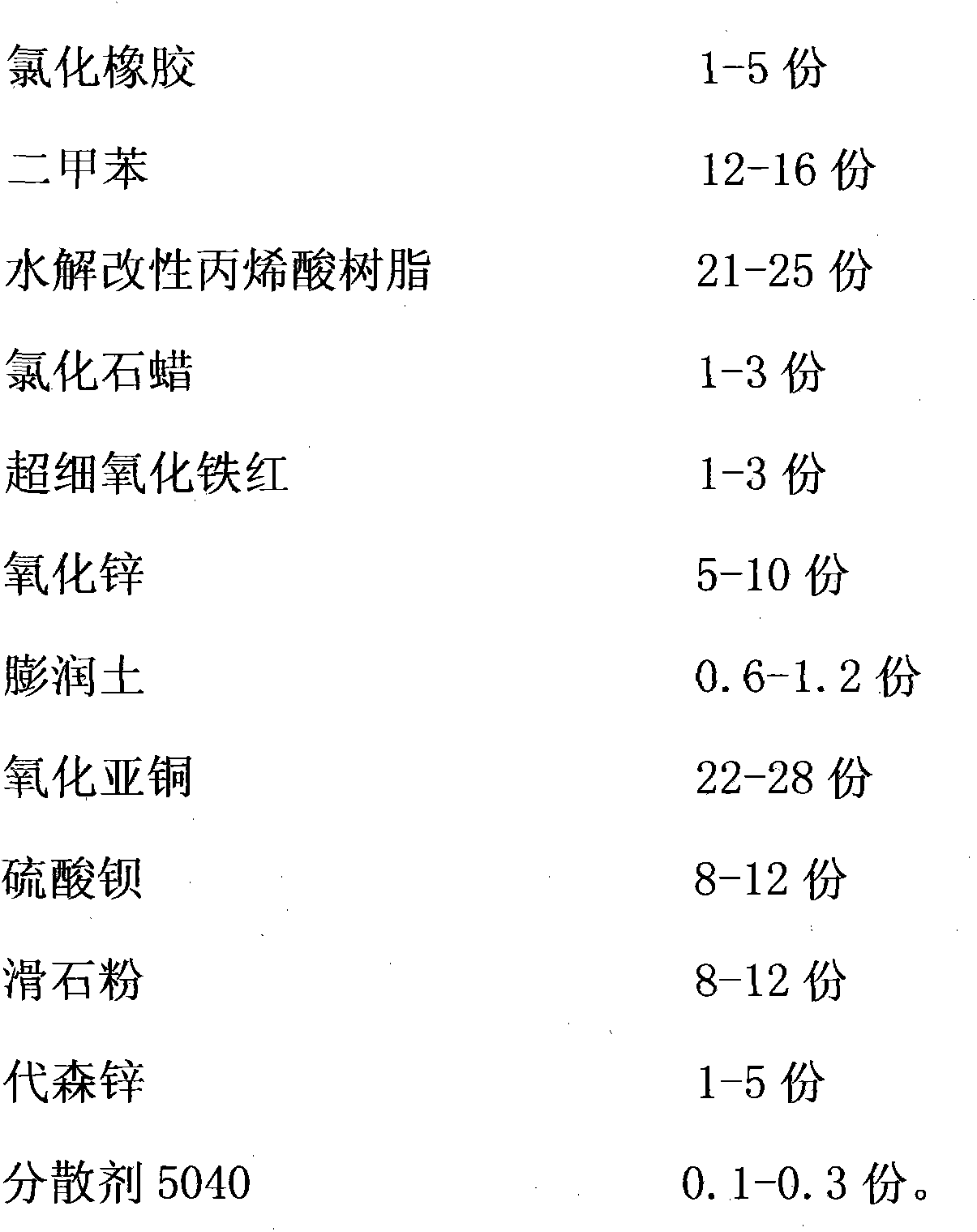

Embodiment 1

[0022] Take 11 parts by mass of hydrolyzed modified acrylic resin and put it into a mixing tank for medium-speed stirring at a stirring speed of 600 rpm, and stir for about 5 minutes; take 0.1 parts by mass of dispersant 5040, add it to the stirring tank for stirring, and then add 1 part by mass of Superfine iron oxide red, 5 parts by mass of zinc oxide, 0.6 parts by mass of bentonite, 22 parts by mass of cuprous oxide, 8 parts by mass of barium sulfate, 8 parts by mass of talc, 1 part by mass of zinc zinc, stirred at high speed for about 20 minutes, and stirred The rotating speed is 1000 revs / min to obtain the slurry; the slurry is moved to a grinder for grinding, and the particle size of the slurry after grinding is less than or equal to 40 microns, so as to effectively reduce the roughness after the film formation of the present invention, and the slurry is controlled during the grinding process. The temperature does not exceed 55°C; add 1 mass part of chlorinated rubber and...

Embodiment 2

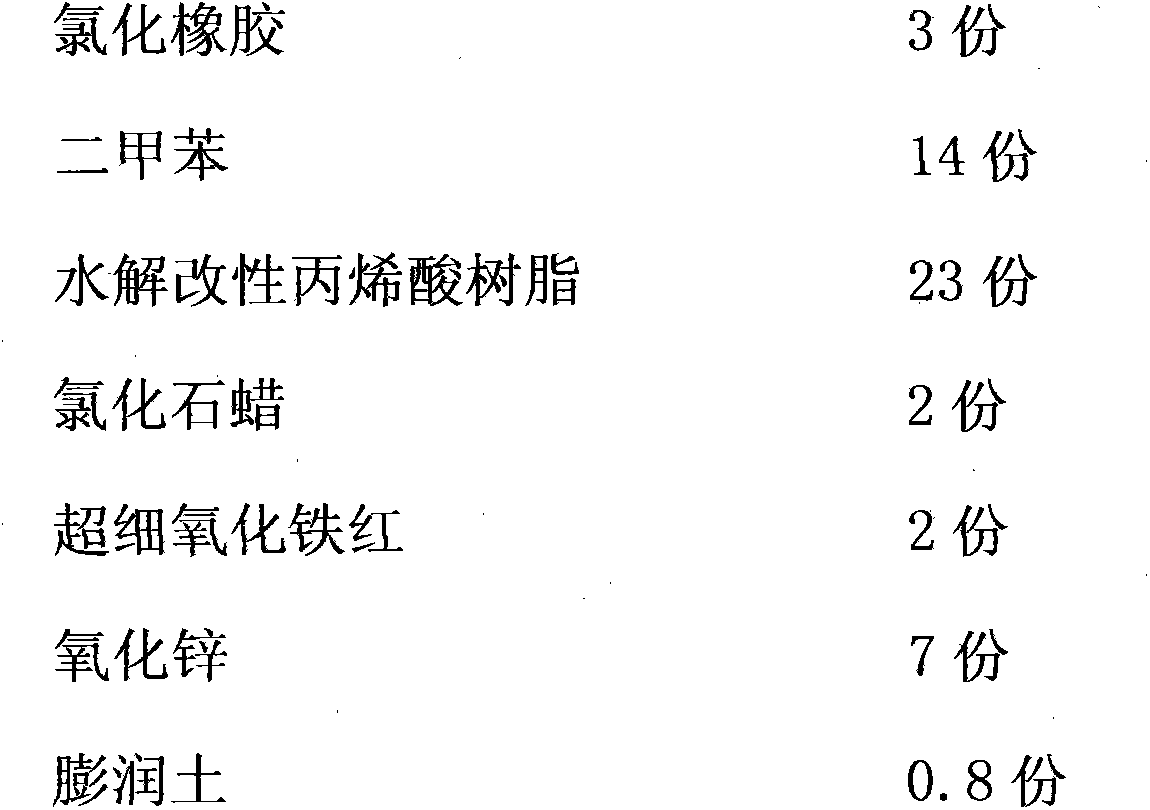

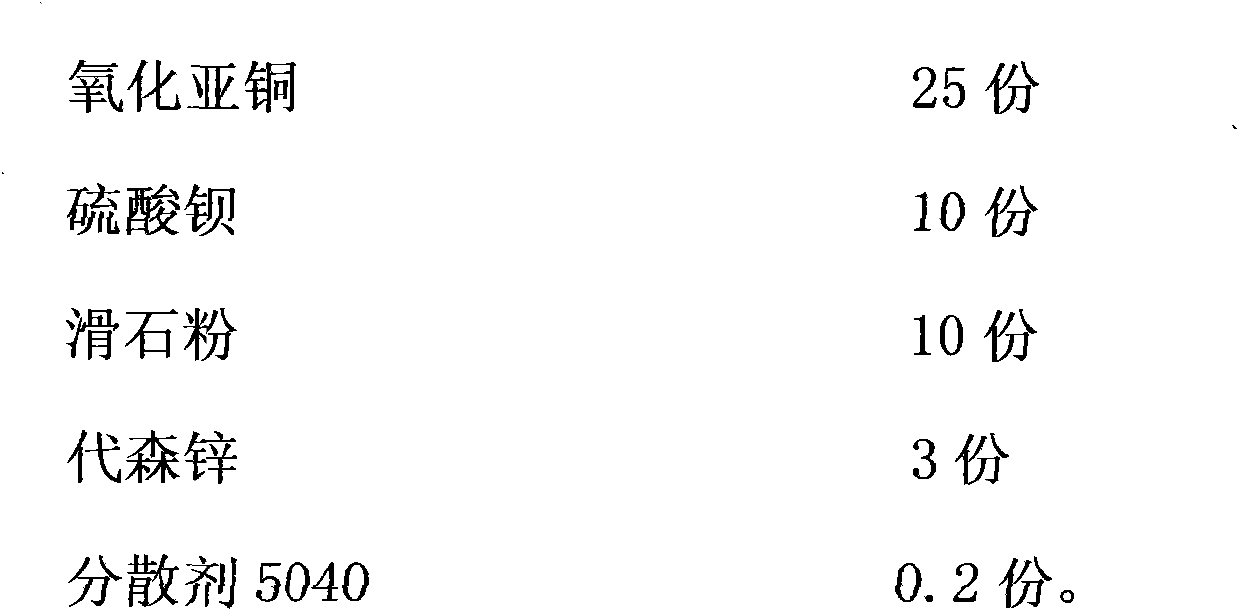

[0024] Take 13 parts by mass of hydrolyzed modified acrylic resin and put it into a mixing tank for medium-speed stirring at a stirring speed of 700 rpm, and stir for about 5 minutes; take 0.2 parts by mass of dispersant 5040, add it to the stirring tank for stirring, and then add 2 parts by mass of Superfine red iron oxide, 7 parts by mass of zinc oxide, 0.8 parts by mass of bentonite, 25 parts by mass of cuprous oxide, 10 parts by mass of barium sulfate, 10 parts by mass of talcum powder, 3 parts by mass of zinc zinc, stirred at high speed for about 20 minutes, and stirred The rotating speed is 1100 revs / min to obtain the slurry; the slurry is moved to a grinder for grinding, and the particle size of the slurry after grinding is less than or equal to 40 microns, so as to effectively reduce the roughness after the film formation of the present invention, and the slurry is controlled during the grinding process. The temperature does not exceed 55°C; 3 parts by mass of chlorinat...

Embodiment 3

[0026] Take 13 parts by mass of hydrolyzed modified acrylic resin and put it into a mixing tank for medium-speed stirring at a stirring speed of 800 rpm, and stir for about 5 minutes; take 0.3 parts by mass of dispersant 5040, add it to the stirring tank for stirring, and then add 3 parts by mass of Superfine red iron oxide, 10 parts by mass of zinc oxide, 1.2 parts by mass of bentonite, 28 parts by mass of cuprous oxide, 12 parts by mass of barium sulfate, 12 parts by mass of talcum powder, 5 parts by mass of zinc zinc, stir at high speed for about 20 minutes, stir The rotating speed is 1200 rpm to obtain the slurry; the slurry is moved to a grinder for grinding, and the particle size of the slurry after grinding is less than or equal to 40 microns, so as to effectively reduce the roughness after the film formation of the present invention, which is conducive to the stable penetration of the poisonous material. During the grinding process, the temperature of the slurry is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com