Preparation method of vetiveria zizanioides L. oil and application of vetiver vetiveria zizanioides L. oil in cigarettes

A technology of vetiver and dried roots, applied in the direction of essential oil/spices, application, tobacco, etc., can solve the problem of low yield of vetiver oil, achieve the effect of improving fragrance, simple equipment and rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

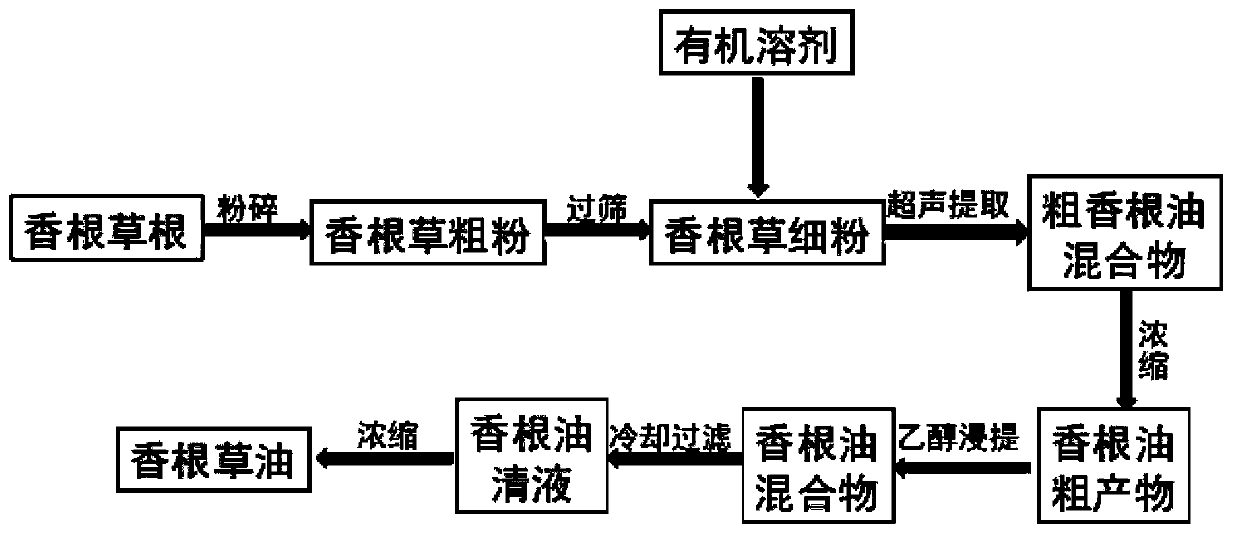

Method used

Image

Examples

Embodiment 1

[0027] The dry root of vetiver was crushed and passed through a 20-mesh sieve, and 200 g of the sieved dry root powder of vetiver was weighed and placed in an extraction container, 3000 mL of ethyl acetate was added, and the temperature was 50 ° C, the power was 1000 W, Ultrasonic extraction was carried out for 60 min at an empty ratio of 80%, repeated 4 times, filtered, combined extracts, the filtrate was distilled under reduced pressure, concentrated to a volume of 200 mL, and ethyl acetate was recovered at the same time. Add 1000 mL of ethanol with a concentration of 95% to the concentrated concentrated solution, stir while adding ethanol, the stirring speed is 600 rpm, and the time for adding ethanol is 10 min. The concentrated solution after adding ethanol was heated at 60° C. for 3 h, the extract was frozen at 4° C. for 24 h, filtered and concentrated to dryness to obtain 15.3 g of vetiver oil.

Embodiment 2

[0029] After crushing the dried vetiver root, pass it through a 60-mesh sieve, weigh 200g of the sieved dried vetiver root powder and place it in an extraction container, add 2000mL of acetone, and set the temperature at 20°C, with a power of 400W and a duty cycle Under the condition of 60% ultrasonic extraction for 20min, repeat 3 times, filter, combine the extracts, distill the filtrate under reduced pressure, concentrate to a volume of 100mL, and recover acetone at the same time. Add 300mL of ethanol with a concentration of 98% to the concentrated concentrated solution, stir while adding ethanol, the stirring speed is 300rpm, and the time for adding ethanol is 5min. The concentrated solution after adding ethanol was heated at 30° C. for 1 h, the extract was frozen at 1° C. for 6 h, filtered with suction and concentrated to dryness to obtain 13.2 g of vetiver oil.

Embodiment 3

[0031] The dry root of vetiver was crushed and passed through a 20-mesh sieve, and 200g of the sieved dry root powder of vetiver was weighed and placed in an extraction container, 2000mL of petroleum ether was added, and the Under the condition of 80% ultrasonic extraction for 40min, repeat 5 times, filter, combine the extracts, distill the filtrate under reduced pressure, concentrate to a volume of 100mL, and recover petroleum ether at the same time. Add 400mL of ethanol with a concentration of 98% to the concentrated concentrated solution, stir while adding ethanol, the stirring speed is 1000rpm, and the time for adding ethanol is 10min. The concentrated solution after adding ethanol was heated at 80° C. for 3 h, the extract was frozen at 1° C. for 12 h, filtered with suction and concentrated to dryness to obtain 18.5 g of vetiver oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com