Method for treating anode mud by swirl electrolysis

A swirling electrolysis and anode slime technology, which is applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of cumbersome process, increased economic loss of enterprises, and large amount of reagents, so as to avoid environmental pollution and improve the quality of purified metal. , The effect of preventing acid mist overflow and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

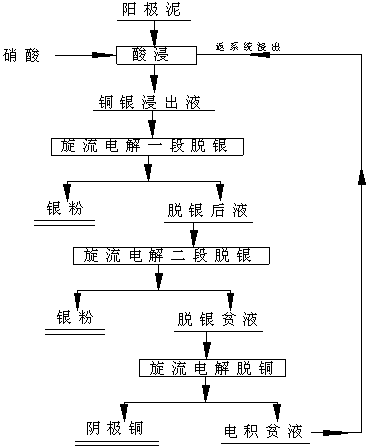

Image

Examples

Embodiment 1

[0034] Take 1000g of anode slime, add nitric acid to slurry according to the liquid-solid ratio of nitric acid and anode slime at 5:1 (ml / g), wherein the concentration of nitric acid is 220g / L, react at 75°C for 3h, and filter to obtain silver copper Leachate;

[0035] The silver-copper leaching solution is filtered with a ceramic membrane precision filter to remove impurities, and the filter residue is returned to step 1) to be mixed with raw materials, and the filtrate is set aside;

[0036] The filtrate enters the cyclone electrolytic cell for electrolytic silver removal, and the pH value of the electrolyte is controlled to be 1.8, and the current density is 700A / m 2 , the electrolysis cycle rate is 300L / h, after continuous electrolysis for 2 hours, silver powder and desilvered solution are obtained, silver powder is washed and dried to obtain 125g of silver powder;

[0037] After desilvering, the liquid is desilvered by two-stage cyclone electrolysis, and the electrolysis...

Embodiment 2

[0040] Take 1000g of anode slime, add nitric acid to slurry according to the liquid-solid ratio of nitric acid and anode slime at 3:1 (ml / g), wherein the concentration of nitric acid is 200g / L, react at 65°C for 4h, filter to obtain silver copper Leachate;

[0041] The silver-copper leachate is finely filtered with a precision filter to remove impurities, and the filter residue is returned to step 1) to be mixed with raw materials, and the filtrate is used for standby;

[0042] The filtrate enters the cyclone electrolytic cell for electrolytic silver removal, and the pH value of the electrolyte is controlled to be 1.5, and the current density is 600A / m 2 , the electrolysis cycle rate is 250L / h, after continuous electrolysis for 2 hours, silver powder and desilvered solution are obtained, silver powder is washed and dried to obtain 100g of silver powder;

[0043] After desilvering, the liquid is desilvered by two-stage cyclone electrolysis, and the electrolysis parameters are:...

Embodiment 3

[0046] Take 1000g of anode slime, add nitric acid to slurry according to the liquid-solid ratio of nitric acid and anode slime at 7:1 (ml / g), wherein the concentration of nitric acid is 250g / L, react at 85°C for 2.5h, filter to obtain silver copper leaching solution;

[0047] The silver-copper leachate is finely filtered with a precision filter to remove impurities, and the filter residue is returned to step 1) to be mixed with raw materials, and the filtrate is used for standby;

[0048] The filtrate enters the cyclone electrolytic cell for electrolytic silver removal, and the pH value of the electrolyte is controlled to be 2.0, and the current density is 800A / m 2 , the electrolysis cycle rate is 400L / h, after continuous electrolysis for 2 hours, silver powder and desilvered solution are obtained, silver powder is washed and dried to obtain 128g of silver powder;

[0049] After desilvering, the liquid is desilvered by two-stage cyclone electrolysis, and the electrolysis para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com