Underflow-type anti-vortex central stopper and nozzle lifting mechanism of electromagnetic induction slag smelter

An electromagnetic induction and slag technology, applied in furnaces, furnace components, charge manipulation, etc., can solve the problems of blocked channels and inability to control the flow of high-temperature slag flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

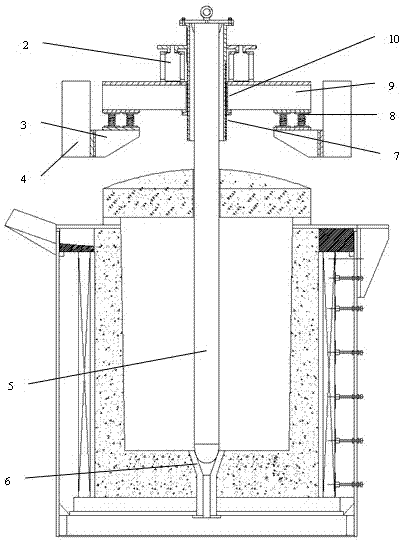

[0028] control attached image 3 , 4 , Electromagnetic induction slag melting furnace bottom flow anti-vortex center stopper nozzle rotation lifting mechanism, its structure includes gear 1, oil motor 2, bracket 3, fixed beam 4, stopper rod 5, graphite material stopper cone single hole nozzle 6, lifting sleeve 7 and spring 8, crossbeam 9, transmission nut 10, oil motor support 11, wherein support 3 is fixed on the fixed beam 4, crossbeam 9 is fixed on the support 3 by spring 8, transmission nut 10 is fixed on the crossbeam 9, lifting sleeve 7 The threaded part on the top is screwed and connected with the transmission nut 10, the oil motor 2 is fixed on the oil motor bracket 11, the gear 1 is connected with the output shaft of the oil motor 2, the gear 1 meshes with the gear of the lifting sleeve 7, and the plug rod 5 is fixed on the lifting sleeve 7 The top, the stopper rod 5 is located at the top of the stopper cone single-hole nozzle 6; the graphite material stopper cone si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com