Method for detecting manganese content in graphene oxide and graphene samples

A manganese content and graphene technology, which is applied in the field of new energy materials, can solve the problems of reduced manganese content accuracy, loss, sample scattering, etc., and achieves the effect of simple method, easy implementation, and satisfactory detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

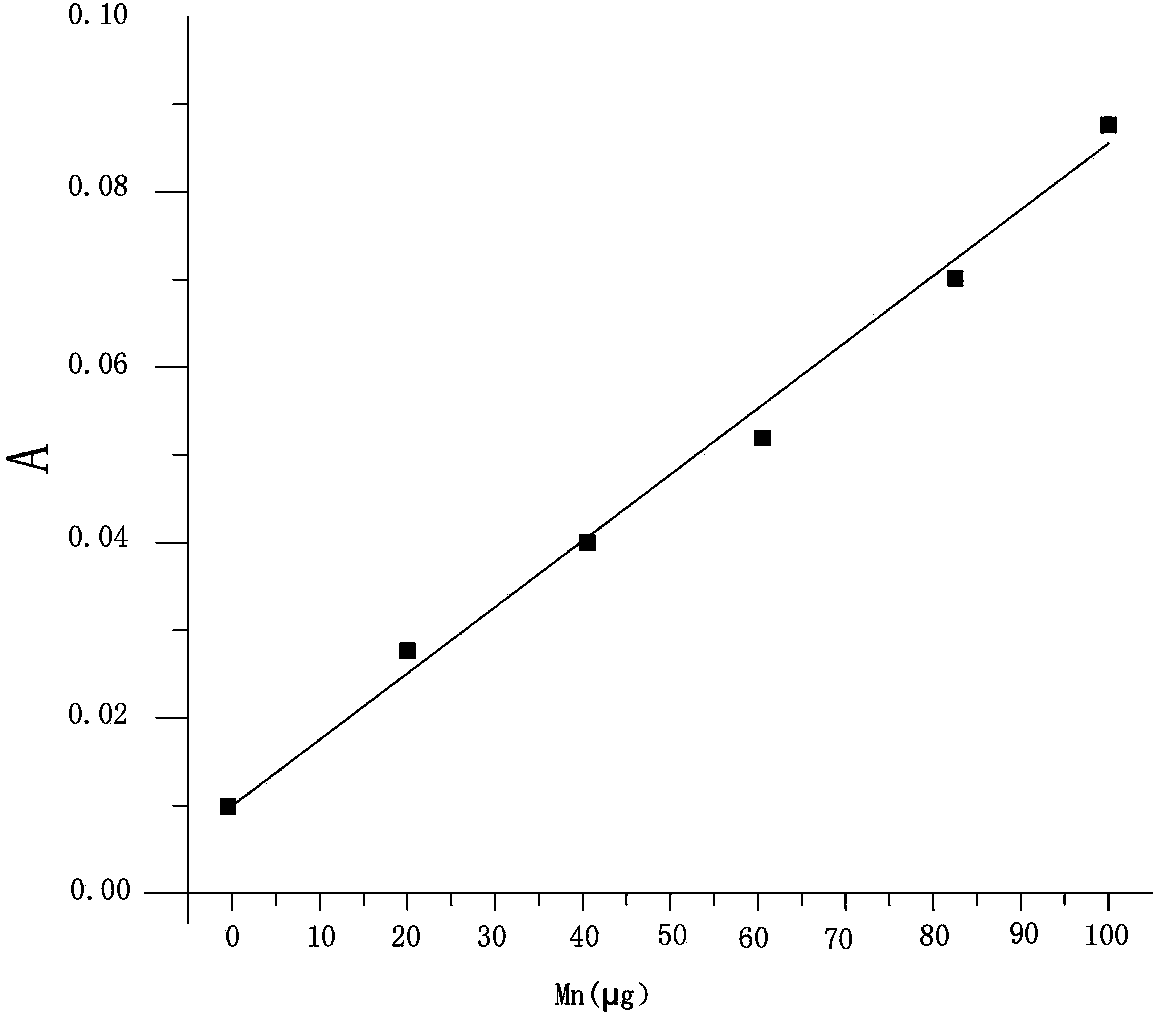

Image

Examples

Embodiment 1

[0022] (1) Accurately weigh 0.5000g of graphene oxide, accurate to 0.0001g;

[0023] (2) Place the sample in a quartz crucible, spread it flat, and add concentrated sulfuric acid dropwise until the sample is completely covered and blackened;

[0024] (3) Place the quartz crucible in an electric furnace and heat it until the yellow smoke dissipates;

[0025] (4) Take it out and place it in a muffle furnace and burn it at 900°C for 4 hours until the sample is completely burned and cooled;

[0026] (5) Add 10 mL of sulfuric acid with a density of 1.84 g / mL and 5 g of ammonium sulfate, cover with a watch glass, heat in an electric furnace until the residue is completely dissolved, cool, and rinse the watch glass and the crucible wall with distilled water;

[0027] (6) Add 1.5mL of nitric acid, add 40mL of distilled water, heat to near boiling, remove, add 0.3g of potassium periodate, heat and boil for 12min, cool, transfer to a 50mL volumetric flask, add distilled water to dilute...

Embodiment 2

[0030] (1) Accurately weigh 0.5000g of graphene, accurate to 0.0001g;

[0031] (2) Place the sample in a quartz crucible, spread it flat, and add concentrated sulfuric acid dropwise until the sample is completely covered and blackened;

[0032] (3) Place the quartz crucible in an electric furnace and heat it until the yellow smoke dissipates;

[0033] (4) Take it out and place it in a muffle furnace and burn it at 900°C for 4 hours until the sample is completely burned and cooled;

[0034] (5) Add 10 mL of sulfuric acid with a density of 1.84 g / mL and 5 g of ammonium sulfate, cover with a watch glass, heat in an electric furnace until the residue is completely dissolved, cool, and rinse the watch glass and the crucible wall with distilled water;

[0035] (6) Add 1.5mL of nitric acid, add 40mL of distilled water, heat to near boiling, remove, add 0.3g of potassium periodate, heat and boil for 12min, cool, transfer to a 50mL volumetric flask, add distilled water to dilute to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com