Temperature compensation system and method of hydrogen sensor with palladium nano structure based on quantum transportation

A technology of temperature compensation and quantum transport, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as error, aging of gas sensitive materials, deviation of numerical relationship between hydrogen pressure or concentration, etc., to achieve a solution The effect of measuring error, reducing production cost, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

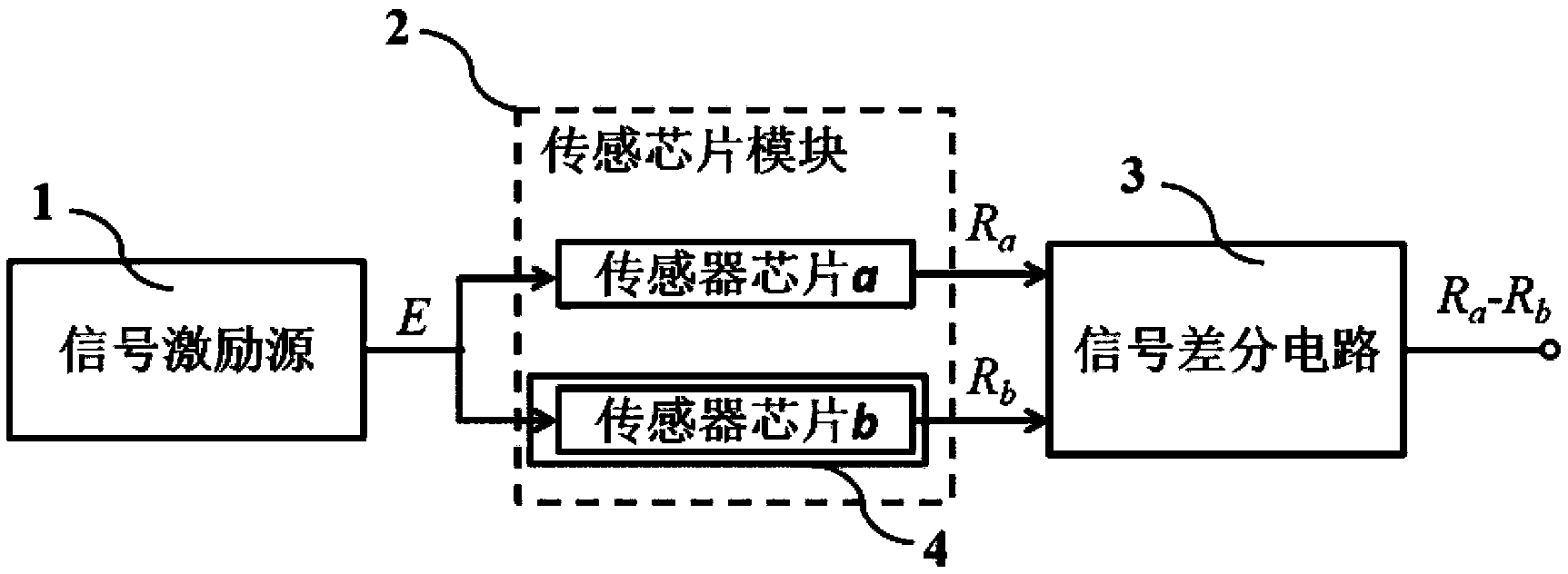

[0034] see figure 1 , a temperature compensation system of a palladium nanostructure hydrogen sensor based on quantum transport, the system includes: a signal excitation source (1), a palladium nanostructure hydrogen sensor chip module (2), a signal differential circuit (3); a signal excitation source (1) is connected with the palladium nanostructure hydrogen sensor chip module (2), and the palladium nanostructure hydrogen sensor chip module (2) is connected with the signal differential circuit (3).

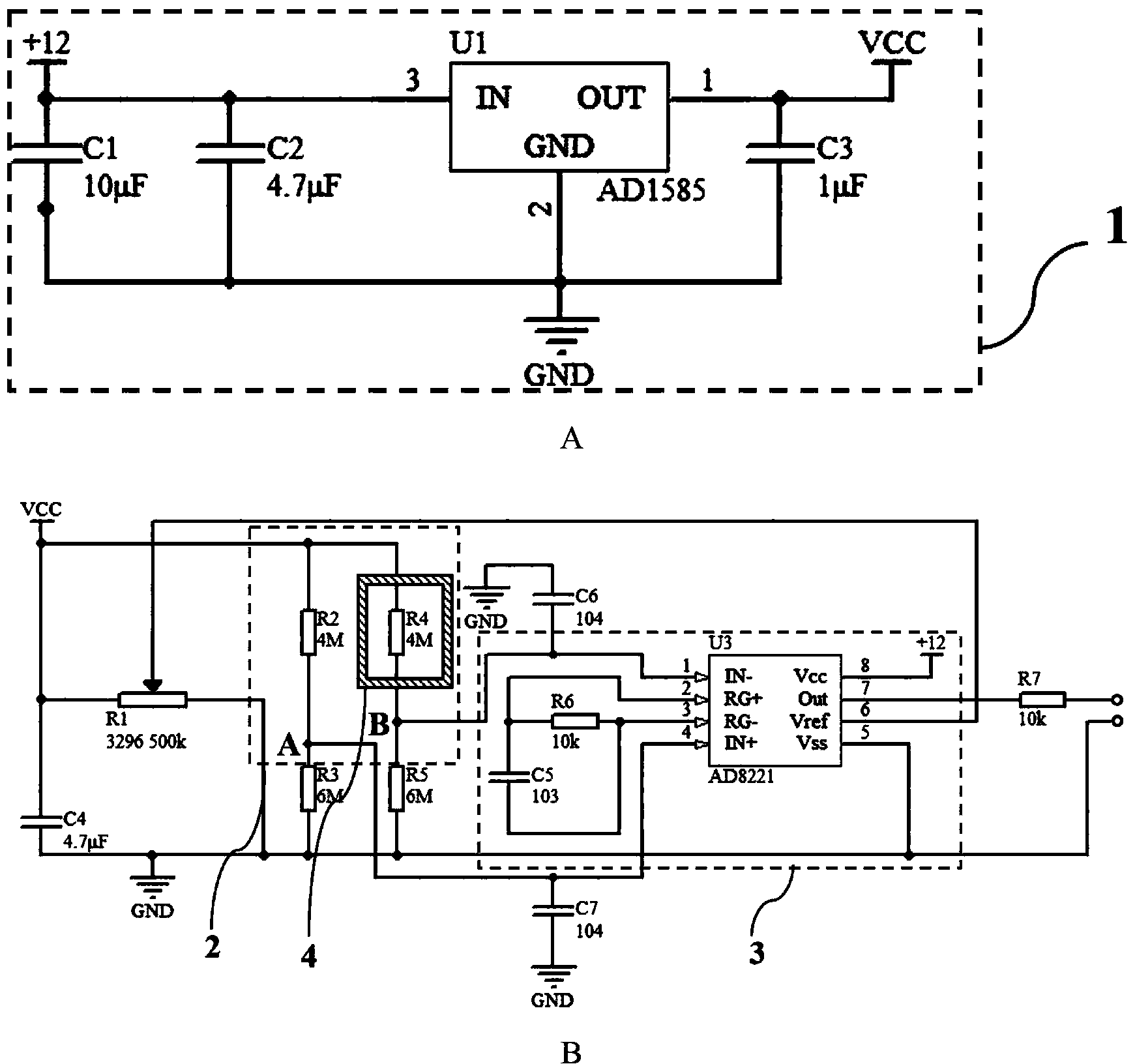

[0035] Such as figure 2 As shown in A, the signal excitation source (1) consists of a voltage regulator chip AD1585 and three capacitors C1, C2 and C3. The input terminal IN of AD1585 is powered by 12V DC voltage, 10μF capacitor C1 and 4.7μF capacitor C2 are connected between the IN terminal and GND terminal, the GND port of AD1585 is grounded, and a 1μF capacitor C3 is connected between the OUT port of AD1585 and GND. The OUT port can output the DC 5V regulated source VCC. ...

Embodiment 2

[0039] A method for temperature compensation with a temperature compensation system of a palladium nanostructure hydrogen sensor based on quantum transport, the specific steps are as follows:

[0040] A. Firstly, using metal palladium as the target, palladium nanoparticles are prepared by plasma gas aggregation method, and the palladium nanoparticles are deposited between the interdigital electrodes, and then a palladium nanostructure hydrogen sensor chip based on the tunneling principle can be obtained a (see patent CN 200910028487), under room temperature conditions, the prepared palladium nanostructure hydrogen sensor chip a The initial resistance value of R2=4MΩ. Another palladium nanostructured hydrogen sensor chip with the same initial resistance R4=4MΩ was prepared by the same method b ;

[0041] B. If figure 2 B, Pd nanostructured hydrogen sensor chip b Sealed in a shell (4) made of copper (or ceramic material), the shell (4) has electrical terminals, through whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial resistance value | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com