Novel carbon fiber nanocone electrode as well as preparation method and application thereof

A carbon fiber and nanocone technology, applied in the fields of electrochemistry and material science, can solve the problems of complex technology, cumbersome operation, difficult batch preparation, etc., and achieve the effects of high temporal and spatial resolution, simplified production steps, and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

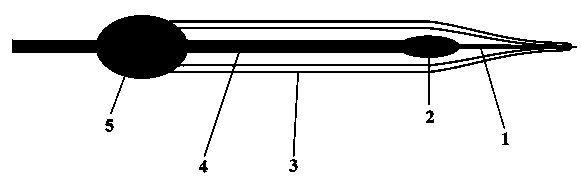

[0034] A new type of carbon fiber nanocone electrode, the schematic diagram of its structure is shown in figure 1 As shown, it includes carbon fiber 1, electrode lead 4 and glass capillary 3; carbon fiber 1 and electrode lead 4 are connected by conductive glue 2, and the front part of carbon fiber 1 is etched into a needle shape at 50-100 μm, and the diameter of the needle-shaped tip is 100-100 μm. 300nm; one end of the glass capillary 3 is drawn into a tip with a diameter less than or equal to 1 μm; the carbon fiber 1 connected to the electrode lead 4 penetrates the pointed glass capillary 3, and the carbon fiber 1 exposes the tip of the glass capillary 3, and the electrode lead 4 exposes the glass capillary 3, this end is sealed with AB glue 5.

[0035] The carbon fiber 1 has a diameter of 5-7 μm and a length of 2-3 cm; the electrode lead 4 is a copper wire with a diameter of 0.3-0.5 mm and a length of 8-12 cm; the conductive glue 2 is graphite Conductive glue (ie epoxy res...

Embodiment 2

[0038] (1) Glue the carbon fiber (Goodfellow Co., Oxford, U.K.) with a diameter of 7 μm and a length of 2 to 3 cm to the electrode lead copper wire (0.4 mm in diameter and about 10 cm in length) with graphite conductive adhesive, and place it at room temperature until the conductive adhesive solidifies; The carbon fibers were ultrasonically cleaned with acetone, ethanol, and double distilled water in sequence, and dried in air.

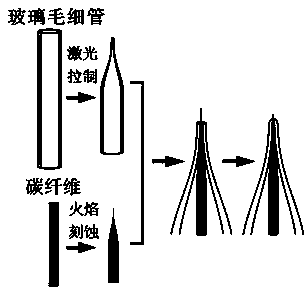

[0039] (2) Put the carbon fiber close to the oxygen-enriched blue flame of the alcohol lamp, and immediately withdraw from the flame when the tip of the carbon fiber is slightly red, and etch the 50-100 μm of the front part of the carbon fiber into a needle shape, and the tip diameter is 100-300nm.

[0040] (3) Pull a clean glass capillary (length 10cm, outer diameter 1.0mm, inner diameter 0.58mm) into a tip with a diameter of about 1 μm (specific parameters are heat=380 ,fil=4,vel=40,del=200,pul=0).

[0041] (4) Insert the carbon fiber connected wit...

Embodiment 3

[0045] (1) Bond the carbon fiber (Goodfellow Co., Oxford, U.K.) with a diameter of 7 μm and a length of 2 to 3 cm to the electrode lead copper wire (0.35 mm in diameter and about 10 cm in length) with graphite conductive adhesive, and place it at room temperature until the conductive adhesive solidifies; Then the carbon fibers were ultrasonically cleaned with acetone, ethanol, and twice distilled water in sequence, and dried in the air.

[0046] (2) Put the carbon fiber close to the oxygen-enriched blue flame of the alcohol lamp, and immediately withdraw from the flame when the tip of the carbon fiber is slightly red, and etch the 50-100 μm of the front part of the carbon fiber into a needle shape, and the tip diameter is 100-300nm.

[0047] (3) Pull a clean glass capillary (length 10cm, outer diameter 1.0mm, inner diameter 0.50mm) into a tip with a diameter of about 1 μm (the specific parameters are heat = 390, fil=5, vel=40, del=200, pul=0).

[0048] (4) Insert the carbon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com