Automatic control system and method of deep-sea net cage bait feeding machine

An automatic control, deep-sea cage technology, applied in general control systems, control/regulation systems, computer control and other directions, can solve the problems of large delivery range, large delivery amount, restricting the development of aquaculture industry, etc., to reduce labor intensity, The effect of strengthening management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

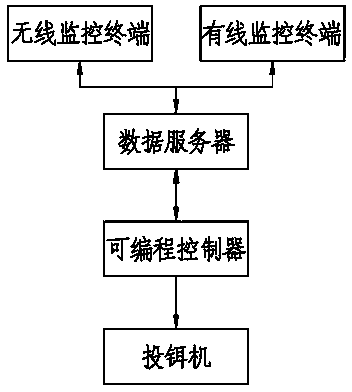

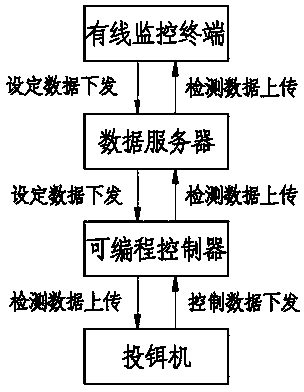

[0023] An automatic control system of a deep-sea cage bait-throwing machine is composed of a monitoring terminal, a data server, a programmable controller and a bait-throwing machine;

[0024] Bait-feeding control software is installed on the monitoring terminal, and the monitoring terminal is connected to the programmable controller through the data server, and sends bait-feeding control instructions to it; Control the bait feeding time interval of the bait feeding machine and the amount of bait feeding; the bait feeding machine feeds back the current working status to the monitoring terminal through the programmable controller.

[0025] According to the actual baiting needs, the operator sets the baiting time interval and baiting amount on the monitoring terminal, and at the same time pre-sets the baiting automation system; after confirming the parameters set on the monitoring terminal, the monitoring terminal Send the parameter information such as the set bait feeding time ...

Embodiment 2

[0027] As in the operation mode described in Embodiment 1, the programmable controller is a wireless programmable controller, and the operator sets the time interval and amount of bait feeding on the monitoring terminal according to the actual bait feeding needs. At the same time, the bait feeding automation system is pre-set. After the input parameters are determined, the monitoring terminal sends the set parameter instructions to the wireless programmable controller through the base transceiver station (BTS) set by the data server. Similarly, the wireless programmable controller feeds back the working information of the equipment and the feeding situation to the data server through the base transceiver station (BTS), and the operator can query the corresponding feeding situation and the operation of the feeding machine through the monitoring terminal Status and other information.

Embodiment 3

[0029] There are two forms of automatic control mode and manual control mode on the monitoring terminal, and operators can choose different control modes according to different practical needs. When manual intervention is required, the operator selects the manual control mode on the monitoring terminal, and then directly selects the operation button on the operation interface to manually control the system as required. At this time, the monitoring terminal sends the control signal to the data server. , and through the control signal output of the data server, directly instruct the programmable controller to perform on-off control of the bait feeder, so that the bait feeder can realize the feeding of bait under manual control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com