Method and device for recovering perfluoro caprylic acid from tail gas produced in fluoropolymer production

A perfluorooctanoic acid and polymer technology, which is applied in the fields of perfluorocarbon/hydrofluorocarbon capture, separation methods, chemical instruments and methods, etc., can solve the problems of affecting the absorption post-treatment process, large alkali consumption, and high industrialization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

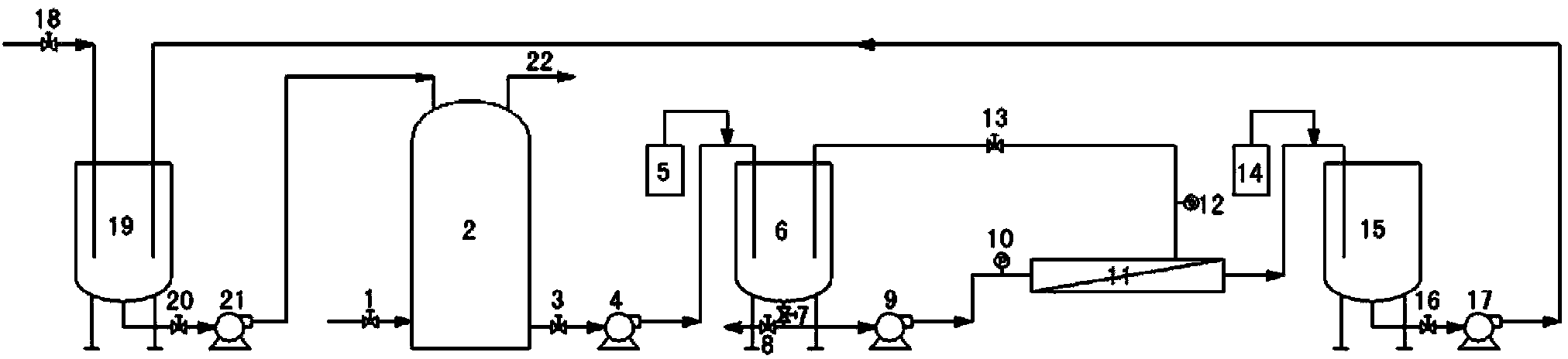

[0021] See figure. A device for recovering perfluorooctanoic acid from fluoropolymer production tail gas, comprising a tail gas inlet valve (1), a packed absorption tower (2), an absorption liquid outlet valve (3), an absorption liquid transfer pump (4), and a pH adjustment system (5 ), absorption liquid buffer tank (6), membrane system feed valve (7), concentrate liquid discharge valve (8), membrane system booster pump (9), membrane inlet pressure gauge (10), flat nanofiltration membrane module (11), membrane outlet pressure gauge (12), membrane system backflow regulating valve (13), pH adjustment system (14), membrane produced water storage tank (15), produced water storage tank outlet valve (16), membrane produced water Transfer pump (17), absorption liquid replenishment valve (18), absorption liquid storage tank (19), absorption liquid storage tank discharge valve (20), absorption liquid feed pump (21), tail gas exhaust port (22).

[0022] Open the absorption liquid reple...

Embodiment 2

[0024] See figure. A device for recovering perfluorooctanoic acid from tail gas produced by fluoropolymers, comprising a tail gas inlet valve (1), a turbulent ball absorption tower (2), an absorption liquid outlet valve (3), an absorption liquid transfer pump (4), and a pH adjustment system ( 5), absorption liquid buffer tank (6), membrane system feed valve (7), concentrate liquid discharge valve (8), membrane system booster pump (9), membrane inlet pressure gauge (10), tubular reverse osmosis Membrane module (11), membrane outlet pressure gauge (12), membrane system backflow regulating valve (13), pH adjustment system (14), membrane product water storage tank (15), product water storage tank outlet valve (16), membrane Product water transfer pump (17), absorption liquid replenishment valve (18), absorption liquid storage tank (19), absorption liquid storage tank discharge valve (20), absorption liquid supply pump (21), exhaust gas outlet (22 ).

[0025]Open the absorption l...

Embodiment 3

[0027] See figure. A device for recovering perfluorooctanoic acid from tail gas produced by fluoropolymers, comprising tail gas inlet valve (1), plate absorption tower (2), absorption liquid outlet valve (3), absorption liquid transfer pump (4), pH adjustment system (5 ), absorption liquid buffer tank (6), membrane system feed valve (7), concentrate liquid discharge valve (8), membrane system booster pump (9), membrane inlet pressure gauge (10), roll-type nanofiltration membrane Component (11), membrane outlet pressure gauge (12), membrane system backflow regulating valve (13), pH adjustment system (14), membrane product water storage tank (15), product water storage tank outlet valve (16), membrane production Water transfer pump (17), absorption liquid replenishment valve (18), absorption liquid storage tank (19), absorption liquid storage tank discharge valve (20), absorption liquid supply pump (21), tail gas vent (22) .

[0028] Open the absorption liquid replenishment va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com