Static flow guide branch pipe dosing type pipeline dosing mixer

A pipeline dosing and mixer technology, which is applied in the directions of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of high dosing operation cost, uneven mixing effect, increased energy consumption, etc., and reduce the dosing operation. The effect of cost, saving drug consumption, low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

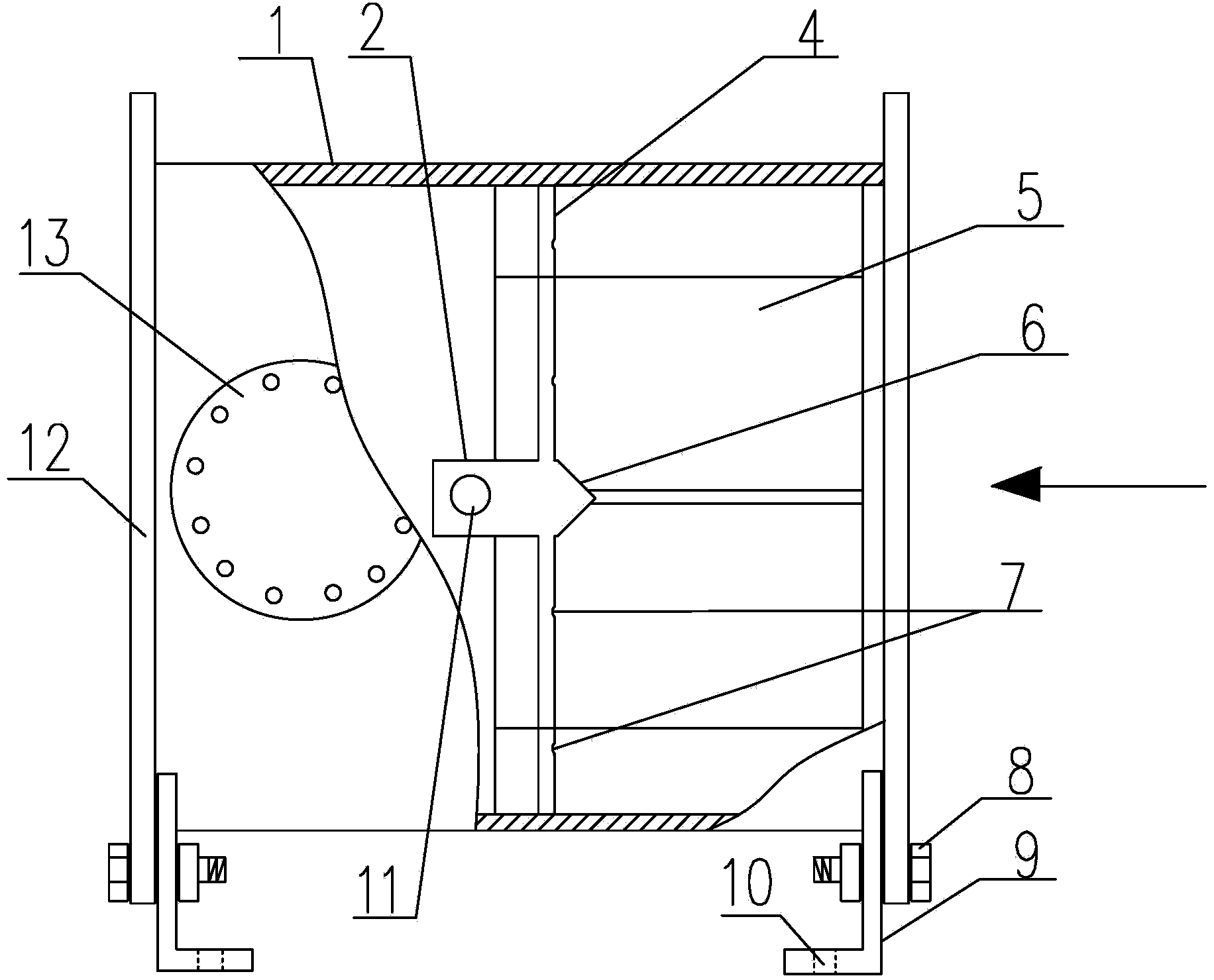

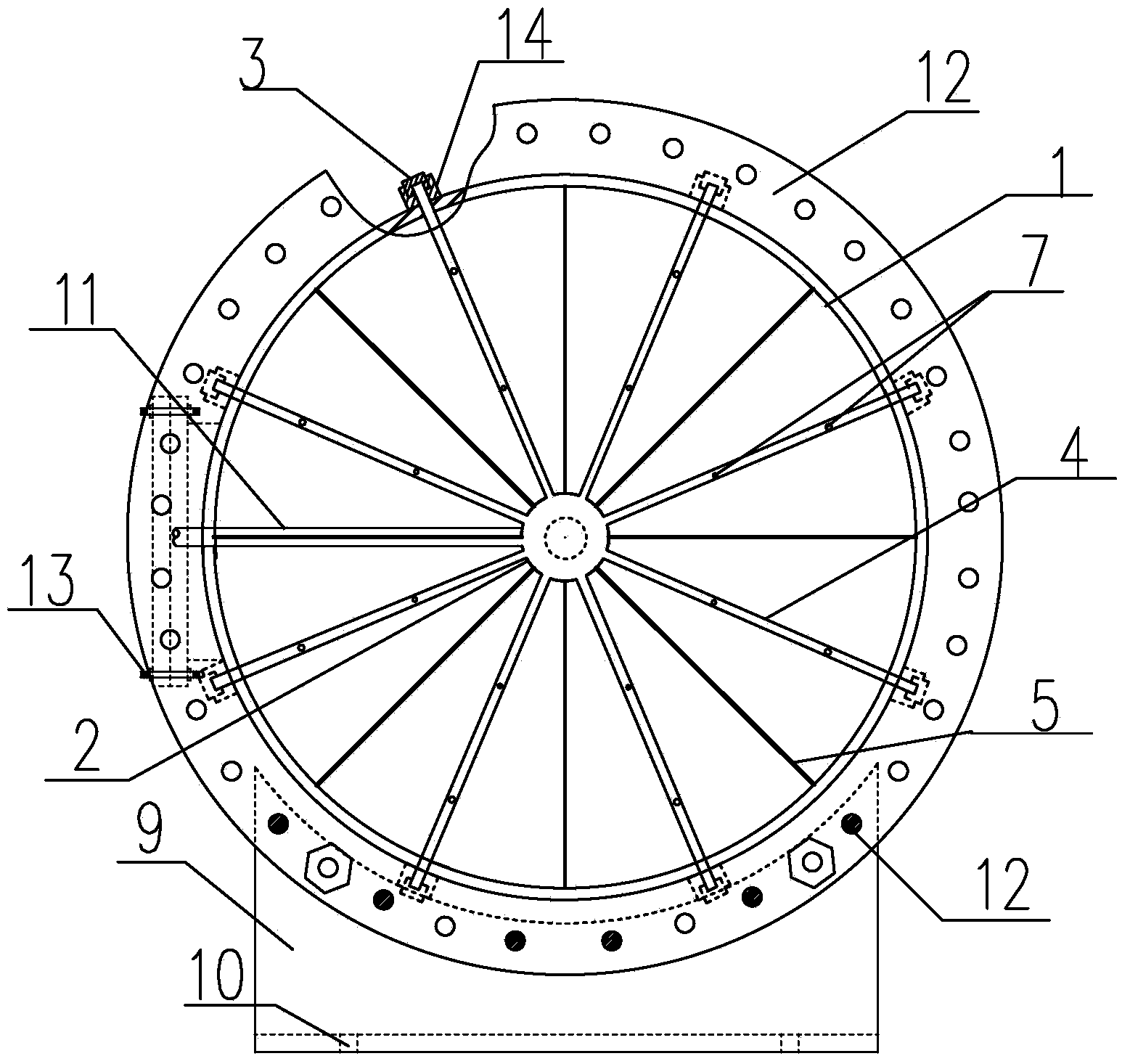

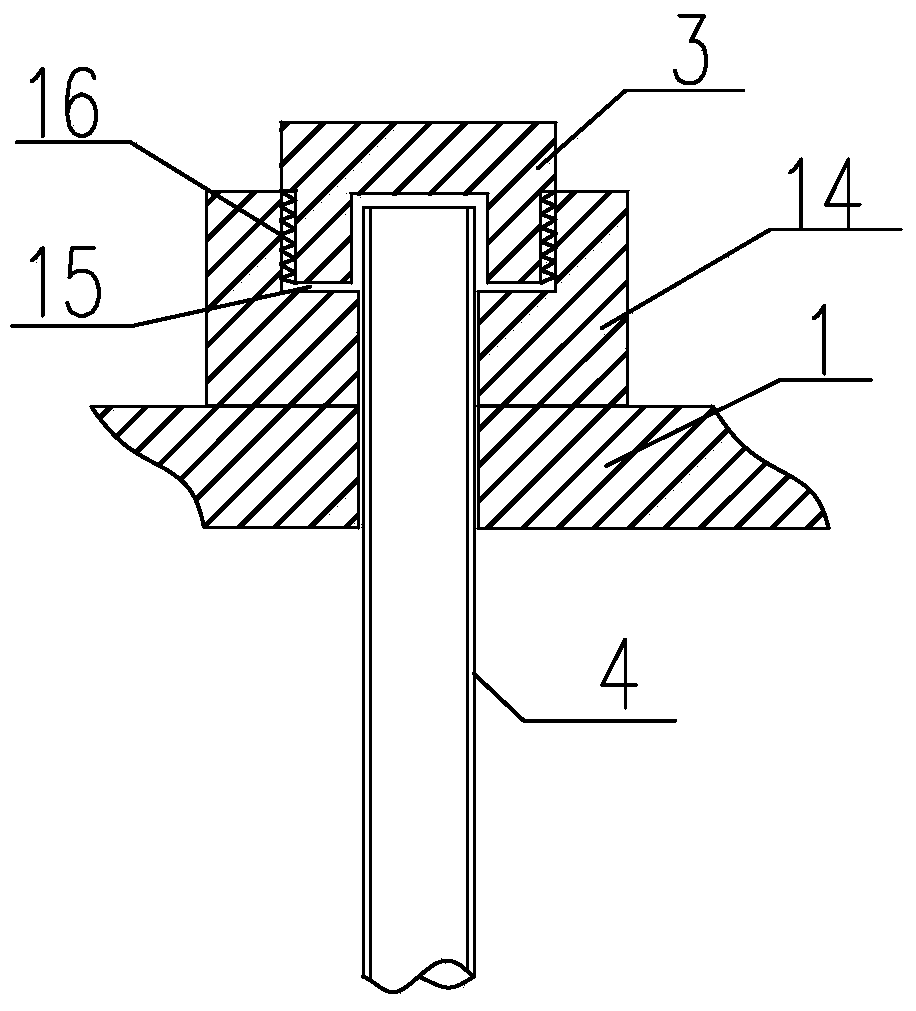

[0017] Figure 1 ~ Figure 3 It shows a static diversion type branch pipe dosing type pipeline dosing mixer, which is characterized in that it includes a cylindrical pipe body 1 connected in the fluid pipeline through flanges 12 at both ends, and at the center of the pipe body 1 A cylindrical dosing central distribution chamber 2 is provided on the same center line as the pipe body, and the outer wall surrounding the dosing central distribution chamber 2 is fixedly arranged between it and the inner wall of the pipe body 1 and radiates along the radial direction of the pipe body. A plurality of guide vanes 5 uniformly distributed in a radial shape and a plurality of dosing branch pipes 4 provided with a drug outlet hole 7 communicated with the distribution chamber 2 of the dosing center on the same plane that are also uniformly distributed radially, the guide vanes 5 extends axially along the pipe body to the water-facing port of the pipe body 1. The dispensing room of the dosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com