Pneumatic honeycomb ceramic biological rotating disc

A biological turntable and honeycomb ceramic technology, applied in the field of biofilm, can solve the problems of single disc shape, low processing efficiency, short service life, etc., and achieve the effects of reducing the floor space, increasing the specific surface area, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make those skilled in the art more clearly understand the purpose and advantages of the present invention, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

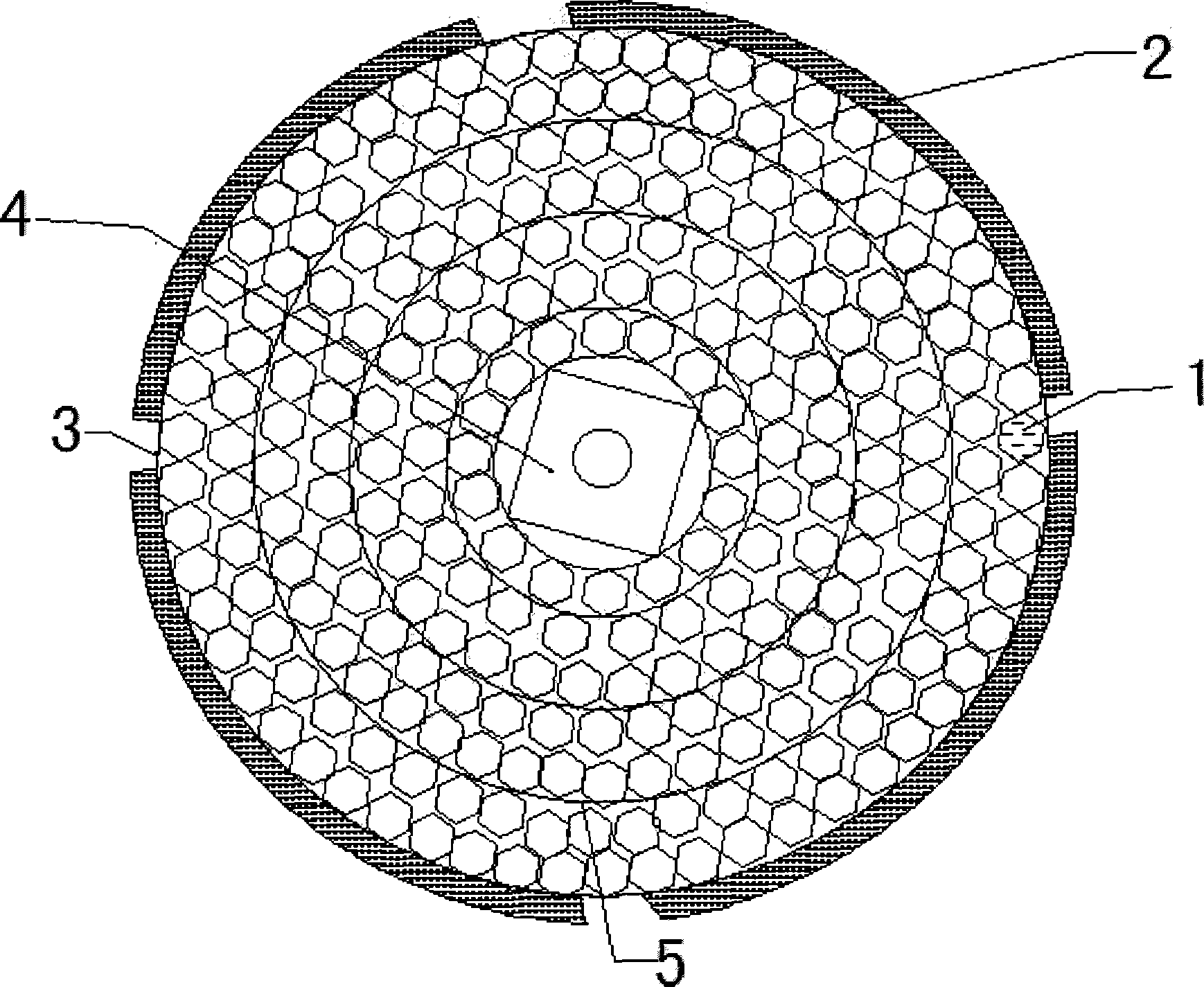

[0017] refer to figure 1 As shown, the pneumatic honeycomb ceramic biological rotary disc disclosed by the present invention comprises a porous honeycomb filler (1), an air groove (2), a disc frame (3), a rotating shaft (4), and a mesh cover (5). The frame (3) is cylindrical, and the two sides of the disc frame (3) are provided with net covers (5), and the center of the disc frame (3) is provided with a rotating shaft (4). Air grooves (2) are arranged on the outer circumference of the disc frame (3), and the porous honeycomb filler (1) is located in the mesh covers (5) on both sides of the disc frame (3). The particle diameter of the porous honeycomb filler (1) is 60 mm to 120 mm, and the material is ceramics. The honeycomb filler (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com