Double Base Tube - Energetic Colloidal Explosives

A double-base tube and colloidal technology, applied to explosives, etc., can solve problems such as safety accidents, high danger, and environmental pollution, and achieve the effects of safe production process, multiple varieties, and high explosive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

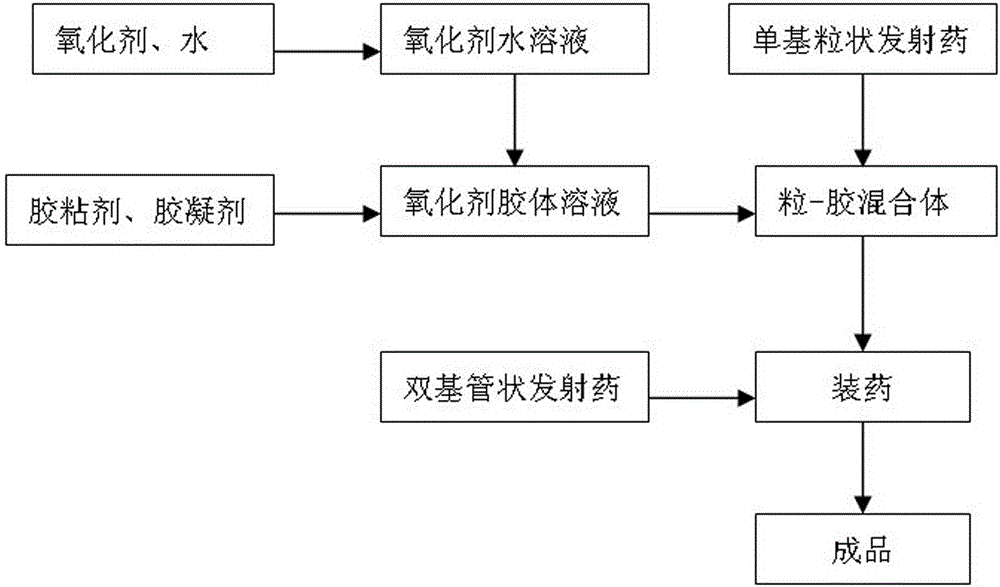

Method used

Image

Examples

Embodiment 1

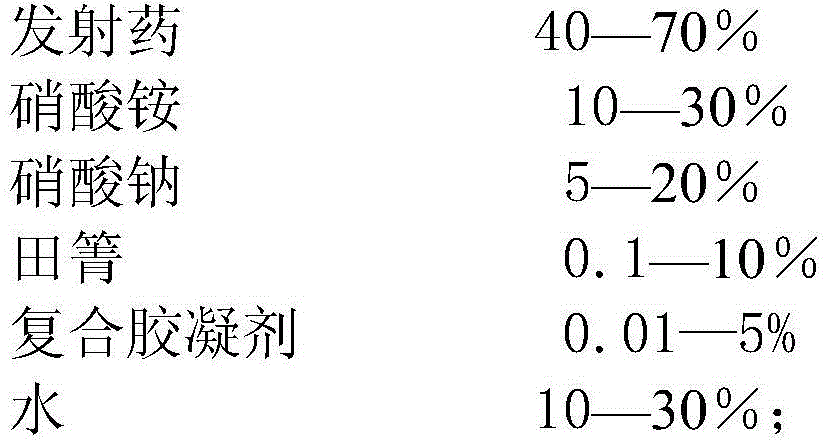

[0029] Double-base tube-energetic colloidal explosive, composed of decommissioned double-base tubular propellant, decommissioned single-base granular propellant, ammonium nitrate, sodium nitrate, Tianqing, urotropine, antimony potassium tartrate, potassium pyroantimonate and water. In this example, the decommissioned double-base tubular propellant uses a double-base tubular propellant with a diameter of 7.00mm and a length of 370mm. The single-base granular propellant uses a mixture of three granular propellants, with particle sizes of 13-15mm, 8- 10mm, 1-3mm, the content ratio is 1:1:1, the oxidizing agent is ammonium nitrate and sodium nitrate, the adhesive is Tianqing, the gelling agent is a compound composed of urotropine, antimony potassium tartrate and potassium pyroantimonate , the content ratio is 1:1:1. Take by weight percentage:

[0030] Double base tubular propellant 20

[0031] Single base granular propellant 30 50

[0032] Ammonium nitrate 18

[0033] Sodium n...

Embodiment 2

[0043] Double-base tube-energetic colloidal explosive, composed of decommissioned double-base tubular propellant, decommissioned single-base granular propellant, ammonium nitrate, sodium nitrate, Tianqing, urotropine, antimony potassium tartrate, potassium pyroantimonate and water. In this example, the decommissioned double-base tubular propellant uses a double-base tubular propellant with a diameter of 7.50 mm and a length of 370 mm. The decommissioned single-base granular propellant uses a mixture of three granular propellants, with particle sizes of 16-18 mm, 8 -10mm, 1-3mm, the content ratio is 1:1:1, the oxidizing agent is ammonium nitrate and sodium nitrate, the adhesive is Tianqing, the gelling agent is a compound composed of urotropine, antimony potassium tartrate and potassium pyroantimonate substance, and its content ratio is 1:2:3. Take by weight percentage:

[0044] Double base tubular propellant 30

[0045] Single base granular propellant 30 60

[0046] Ammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com