Industrial production method of 3-cyano-3,5,5-trimethylcyclohexanone

A technology of isophorone and isophoronenitrile, applied in the field of organic chemical synthesis, can solve problems such as difficult handling of solid cyanide-containing waste, high requirements for production equipment, and difficulty in industrialized production, and achieve low production cost and simple process , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

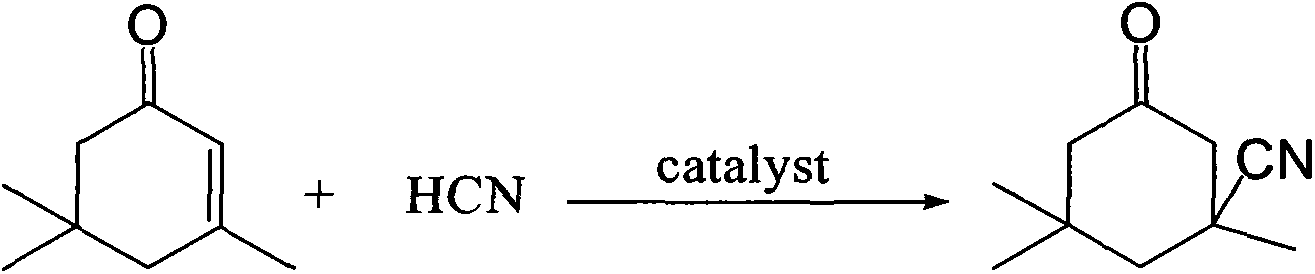

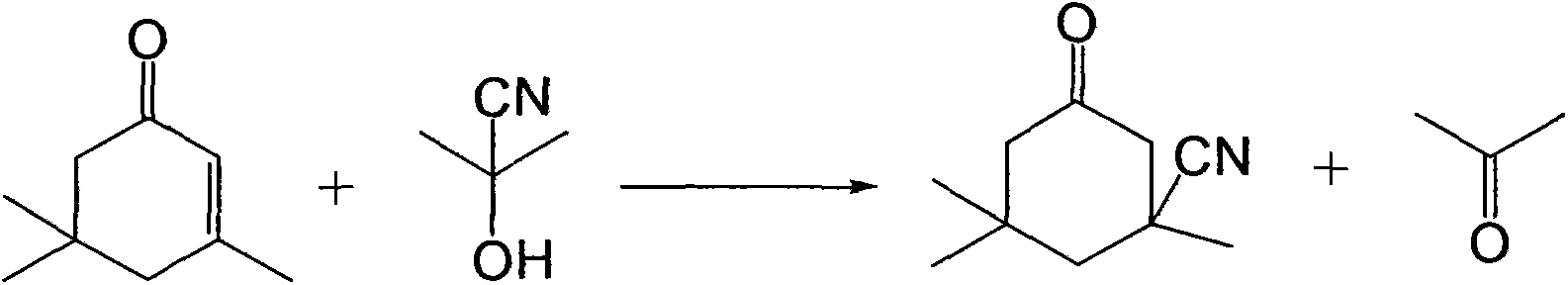

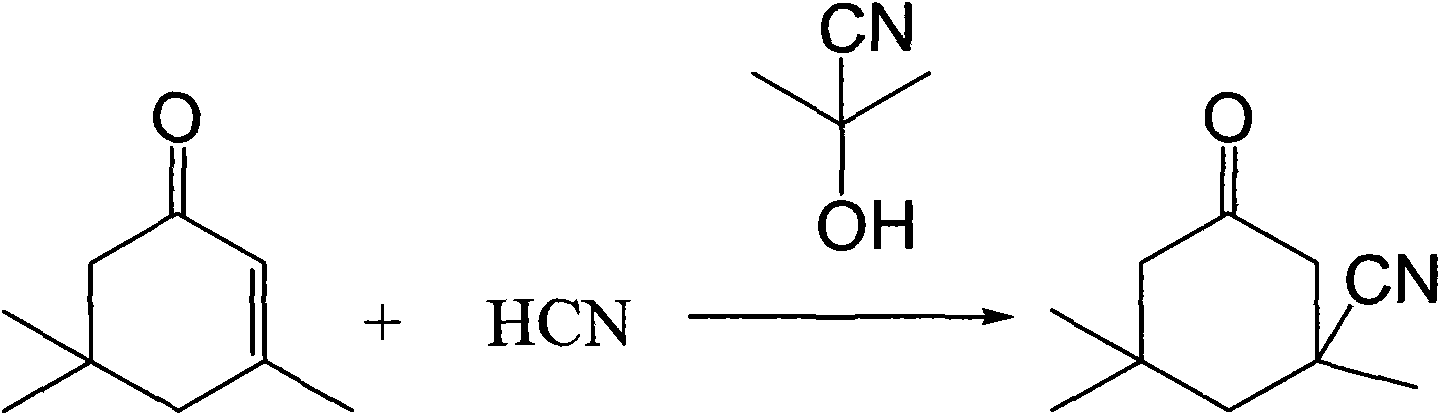

Method used

Image

Examples

Embodiment 1

[0028] Add 138g (1.0mol) of isophorone to a four-neck flask with stirring and a thermometer, raise the temperature to 100°C, add 4.3g (0.05mol) of acetone cyanohydrin, and feed hydrogen cyanide gas to control the amount of gas At 40g (1.5mol), keep the temperature at 100°C, react for 1 hour, cool down to 5°C, filter, and dry to obtain 153g of light yellow isophoronenitrile product with a content of 97.3% and a yield of 95.6%.

Embodiment 2

[0030] Add 138g (1.0mol) of isophorone to a four-necked flask with stirring and a thermometer, raise the temperature to 200°C, add 0.85g (0.01mol) of acetone cyanohydrin, and feed hydrogen cyanide gas to control the amount of gas At 33g (1.2mol), keep the temperature at 200°C, react for 0.5 hours, cool down to 0°C, filter, and dry to obtain 146.4g of light yellow isophoronenitrile product with a content of 95.3% and a yield of 93.2%.

Embodiment 3

[0032] Add 138g (1.0mol) of isophorone to a four-neck flask with stirring and a thermometer, raise the temperature to 150°C, add 1.7g (0.02mol) of acetone cyanohydrin, and feed hydrogen cyanide gas to control the amount of gas At 35g (1.3mol), keep the temperature at 150°C, react for 0.7 hours, cool down to -5°C, filter, and dry to obtain 152.8g of light yellow isophoronenitrile product with a content of 98.3% and a yield of 94.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com