Broad-spectrum antimicrobial fragrant polypropylene resin for washing machine, and preparation method thereof

A polypropylene resin and washing machine technology, which is applied in the field of broad-spectrum antibacterial and fragrant polypropylene resin for washing machines and its preparation field, can solve the problems of insignificant effect of inorganic antibacterial agents on mold and insignificant effect of organic antibacterial agents on bacteria, and achieve a wide range of antibacterial agents. , not easy to lose, not easy to deform the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 comparative example 1 and comparative example 2

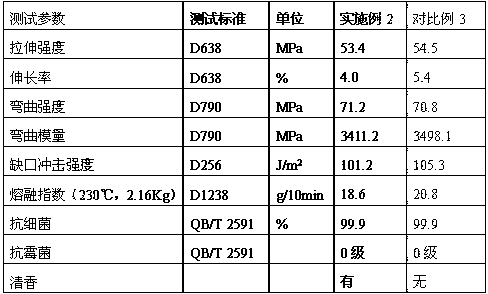

[0029] The impact of embodiment 1, comparative example 1 and comparative example 2 antibacterial agent

[0030] Polypropylene is homopolypropylene, small molecule organic antibacterial agent is triclosan, inorganic antibacterial agent is silver ion glass inorganic powder, compatibilizer is polypropylene grafted maleic anhydride, dispersant is polyethylene wax, antioxidant The agent is Antioxidant 1010. Each raw material was weighed according to the weight percentage shown in Table 1.

[0031] The weight percent of each raw material in table 1 embodiment 1, comparative example 1 and comparative example 2

[0032]

[0033] Mix polypropylene, small-molecule organic antibacterial agent, inorganic antibacterial agent, fragrance agent, compatibilizer, dispersant and antioxidant in a high mixer for 2 minutes, and discharge; the resulting mixture is placed in a twin-screw extrusion Extrude and granulate in the machine. During the extrusion process, glass fiber is added at the si...

Embodiment 2 and comparative example 3

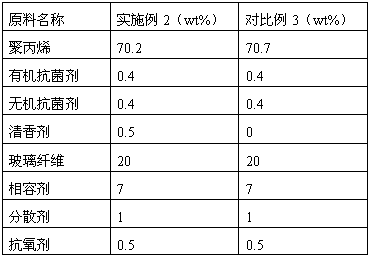

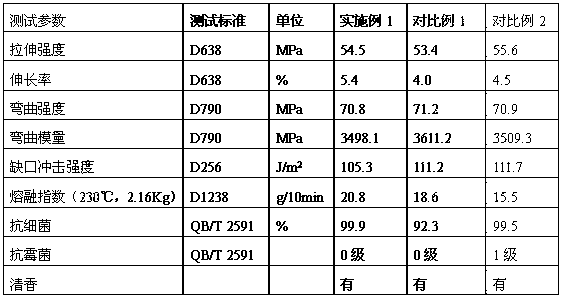

[0037] The impact of embodiment 2 and comparative example 3 fresh fragrance

[0038] Polypropylene is copolymerized polypropylene, small molecule organic antibacterial agent is quaternary ammonium salt, inorganic antibacterial agent is silver ion zeolite inorganic powder, glass fiber is alkali-free glass fiber, compatibilizer is polypropylene grafted maleic anhydride, dispersant It is stearic acid amide, and the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1. Each raw material was weighed according to the weight percentage shown in Table 3.

[0039] The weight percent of each raw material in table 3 embodiment 2 and comparative example 3

[0040]

[0041] Mix polypropylene, small molecule organic antibacterial agent, inorganic antibacterial agent, fragrance agent, compatibilizer, dispersant and antioxidant in a high mixer for 5 minutes and discharge; put the resulting mixture into a twin-screw extruder Extrude and granulate in th...

Embodiment 3

[0046] Polypropylene is homopolypropylene and copolymerized polypropylene with a weight ratio of 1:1, the small molecule organic antibacterial agent is triclosan, the inorganic antibacterial agent is silver ion glass inorganic powder, and the glass fiber is alkali-free glass fiber, which is compatible with The agent is polypropylene grafted maleic anhydride, the dispersant is polyethylene wax, and the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1. Take each raw material according to the following weight percentages:

[0047] Polypropylene 60%, small molecule organic antibacterial agent 1%, inorganic antibacterial agent 1%, fragrance agent 0.1%, glass fiber 30%, compatibilizer 7.7%, dispersant 0.1%, antioxidant 0.1%.

[0048] Mix polypropylene, small molecule organic antibacterial agent, inorganic antibacterial agent, fragrance agent, compatibilizer, dispersant and antioxidant in a high-mixer for 3 minutes, and discharge; put the resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com