A method for producing ethanol, butanol and acetone by segmenting mixed sugar containing pentose and hexose and mixed bacteria fermentation

A technology of mixed bacteria fermentation and mixed sugar, which is applied in the field of fermentation to produce ethanol, butanol and acetone, to reduce environmental pollution, ensure safety and promote diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

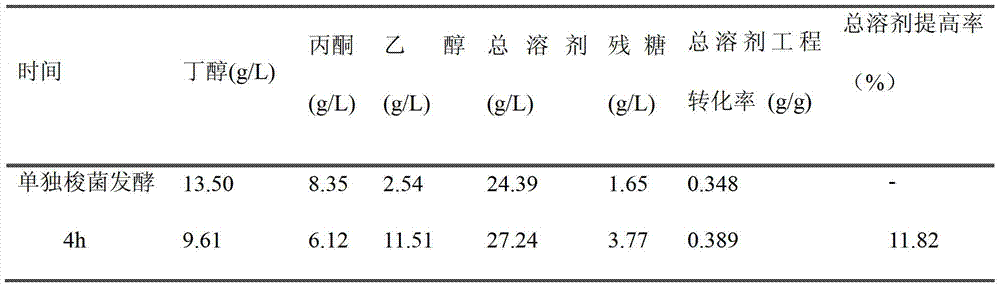

[0020] Example 1: Production of ethanol, butanol and acetone by segmenting corn stalk hydrolyzate and mixed bacteria fermentation

[0021] The fermentation medium is: total sugar is 70g / l, of which pentose is 30g / l (accounting for 42.8% of total sugar), adding organic additives (mixed preparation of various agricultural and sideline products, rich in phosphorus and nitrogen, including bran, rice bran , bean cake powder and bean cake, etc.) 7g / l (the quality of the nitrogen source and phosphorus source is 10% of the total sugar mass in the hydrolyzate). Mix well, dispense into 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml. Sterilize at 135°C for 20 minutes in a sterilizer. After sterilization, cool to 37°C, insert Clostridium acetobutylicum, and anaerobically ferment at 37°C for 4 hours, 24 hours, 48 hours, and 72 hours, then respectively insert Saccharomyces cerevisiae at 28°C to continue anaerobic fermentation until the total fermentation time 144 ho...

Embodiment 2

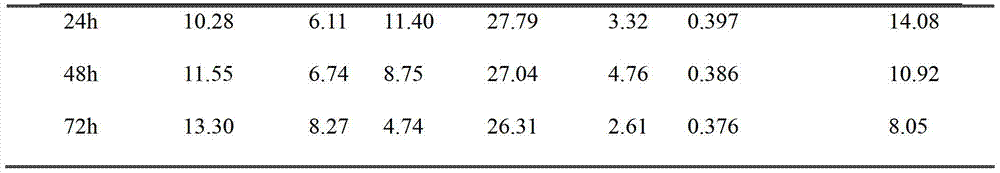

[0025] Example 2: Select corn stalk hydrolyzate to segment and mix bacteria to ferment to produce ethanol, butanol and acetone

[0026] The fermentation medium is: total sugar is 70g / l, wherein pentose is 35g / l (accounting for 50% of total sugar), bran 35g / l is added (the quality of the nitrogen source and phosphorus source is the total sugar mass in the hydrolyzate 50% of Mix well, dispense into 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml. Sterilize at 115°C for 60 minutes in a sterilizer. After sterilization, cool to 28°C, insert Saccharomyces cerevisiae, and carry out anaerobic fermentation at 28°C for 4 hours, 24 hours, 48 hours, and 72 hours, respectively insert Clostridium acetobutylicum and continue anaerobic fermentation at 37°C until the total fermentation time 168 hours. After the fermentation is complete, get 1ml of fermented liquid and place it in a centrifuge tube, centrifuge for 7 minutes at a speed of 11000 rpm, and measure the conte...

Embodiment 3

[0029] Example 3: Production of ethanol, butanol and acetone by segmenting corn stalk hydrolyzate and mixed bacteria fermentation

[0030]The fermentation medium is: total sugar is 70g / l, of which pentose is 30g / l (accounting for 42.8% of total sugar), bean cake powder is added 14g / l (the quality of the nitrogen source and phosphorus source is the total sugar mass in the hydrolyzate 20% of Mix well, dispense into 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml. Sterilize at 115°C for 60 minutes in a sterilizer. After sterilization, cool to 37°C, insert Clostridium acetobutylicum, insert Saccharomyces cerevisiae after anaerobic fermentation at 37°C for 18 hours, and continue anaerobic fermentation at 28°C for 30 hours, 48 hours, 72 hours, 96 hours, 120 hours , 144 hours, 168 hours. After the fermentation is complete, get 1ml of fermented liquid and place it in a centrifuge tube, centrifuge for 7 minutes at a speed of 11000 rpm, and measure the contents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com