Method for producing ethanol, butanol and acetone by utilizing segmented and mixed fermentation of mixed sugar containing pentose and hexose

A technology of mixed bacteria fermentation and sugar mixing, applied in the field of fermentation production of ethanol, butanol and acetone, to reduce environmental pollution, ensure safety, and promote diversification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

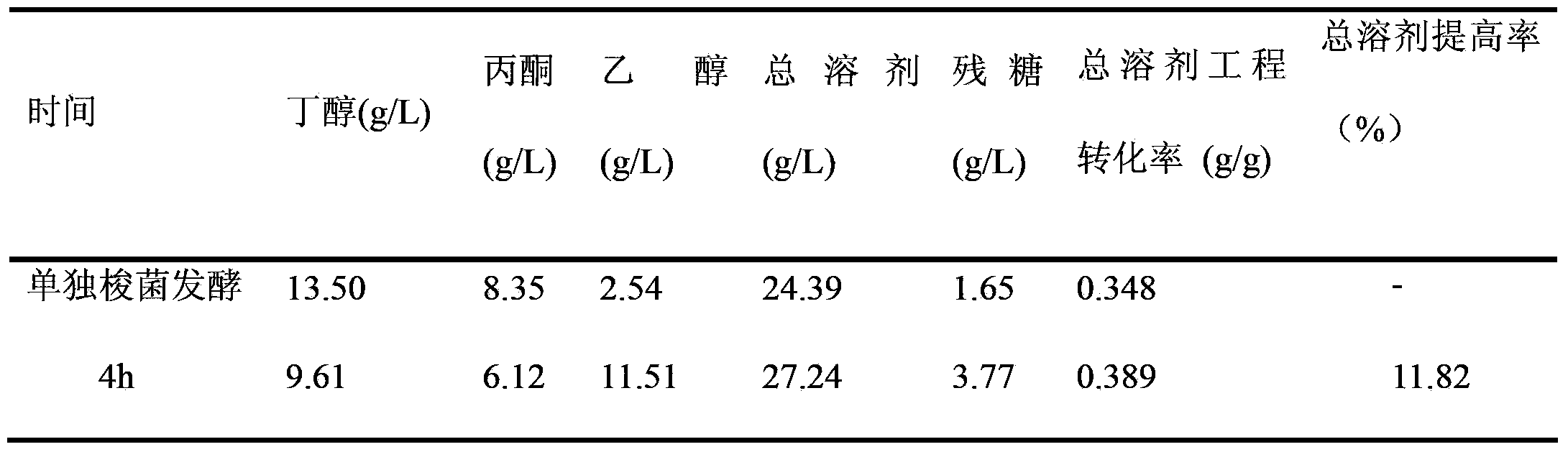

[0020] Example 1: Production of ethanol, butanol and acetone by segmenting corn stalk hydrolyzate and mixed bacteria fermentation

[0021] The fermentation medium is: total sugar is 70g / l, of which pentose is 30g / l (accounting for 42.8% of total sugar), adding organic additives (mixed preparation of various agricultural and sideline products, rich in phosphorus and nitrogen, including bran, rice bran , bean cake powder and bean cake, etc.) 7g / l (the quality of the nitrogen source and phosphorus source is 10% of the total sugar mass in the hydrolyzate). Mix well, dispense into 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml. Sterilize at 135°C for 20 minutes in a sterilizer. After sterilization, cool to 37°C, insert Clostridium acetobutylicum, and anaerobically ferment at 37°C for 4 hours, 24 hours, 48 hours, and 72 hours, then respectively insert Saccharomyces cerevisiae at 28°C to continue anaerobic fermentation until the total fermentation time 144 ho...

Embodiment 2

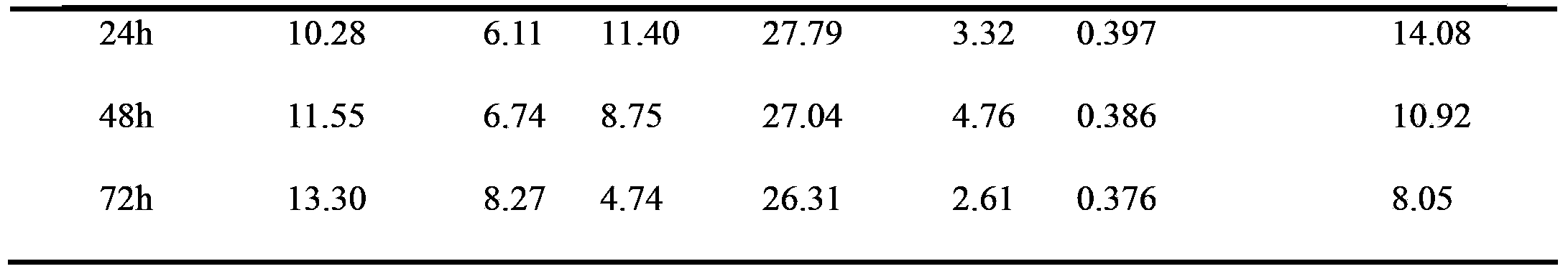

[0025] Example 2: Select corn stalk hydrolyzate to segment and mix bacteria to ferment to produce ethanol, butanol and acetone

[0026] The fermentation medium is: total sugar is 70g / l, wherein pentose is 35g / l (accounting for 50% of total sugar), bran is added 35g / l (the quality of the nitrogen source and phosphorus source is the total sugar mass in the hydrolyzate 50% of Mix well, dispense into 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml. Sterilize at 115°C for 60 minutes in a sterilizer. After sterilization, cool to 28°C, insert Saccharomyces cerevisiae, and carry out anaerobic fermentation at 28°C for 4 hours, 24 hours, 48 hours, and 72 hours, respectively insert Clostridium acetobutylicum and continue anaerobic fermentation at 37°C until the total fermentation time 168 hours. After the fermentation is complete, get 1ml of fermented liquid and place it in a centrifuge tube, centrifuge at a speed of 11000 rpm for 7 minutes, and use gas chromatog...

Embodiment 3

[0029] Example 3: Production of ethanol, butanol and acetone by segmenting corn stalk hydrolyzate and mixed bacteria fermentation

[0030]The fermentation medium is: total sugar is 70g / l, of which pentose is 30g / l (accounting for 42.8% of total sugar), bean cake powder is added 14g / l (the quality of the nitrogen source and phosphorus source is the total sugar mass in the hydrolyzate 20% of Mix well, dispense into 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml. Sterilize at 115°C for 60 minutes in a sterilizer. After sterilization, cool to 37°C, insert Clostridium acetobutylicum, insert Saccharomyces cerevisiae after anaerobic fermentation at 37°C for 18 hours, and continue anaerobic fermentation at 28°C for 30 hours, 48 hours, 72 hours, 96 hours, 120 hours , 144 hours, 168 hours. After the fermentation is complete, get 1ml of fermented liquid and place it in a centrifuge tube, centrifuge at a speed of 11000 rpm for 7 minutes, and use gas chromatograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com