A composite treatment method for diamond surface metallization

A technology for surface metal and composite treatment, applied in the field of diamond particle surface modification, can solve the problems of diamond surface metallization that have not been publicly reported, and achieve the effects of shortening treatment time, simple equipment and low deposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

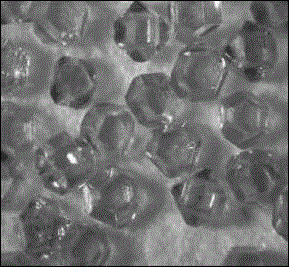

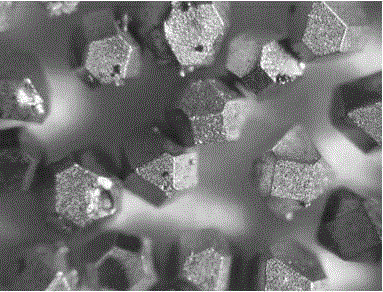

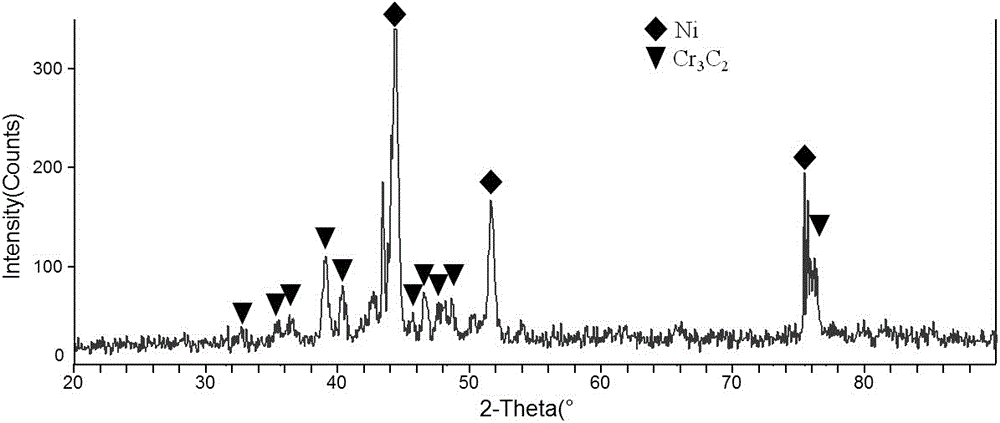

[0022] The Ni-Cr-P coating is prepared on the diamond surface by chemical plating, and the diamond particles are 150-180 μm. figure 1 Its stereomicroscopic appearance. Bath composition includes NiSO 4 ·7H 2 O 10-20g / L, CrCl 3 ·6H 2 O 10-15g / L, NaH 2 PO 2 ·H 2 O 35-45g / L, C 6 H 8 O 7 ·H 2 O 30-35g / L, C 3 H 6 O 3 10-20g / L, NH 4 Cl 30-50g / L, use ammonia water and 30% acetic acid to adjust the pH value of the plating solution to 7-9, introduce diamond particles into the plating solution, apply ultrasonic plating with mechanical stirring, the temperature of the water bath is 85 ° C, the time is 1 hour, take out after cooling Electroless plated diamond particles, washed with water and dried. Mix the diamond particles with the zirconia ball mill to make the diamond particles completely embedded, then place the mixture in a corundum crucible with a capacity of 500ml to cover, and then place it in a vacuum microwave heating furnace for 20 minutes, and the microwave powe...

Embodiment 2

[0024] The Ni-Cr-W-P coating is prepared on the diamond surface by electroless plating, the diamond particles are 150-180 μm, and the composition of plating solution 1 includes NiSO 4 ·7H 2 O 20-30g / L, Na 2 WO 4 ·2H 2 O 50-70g / L, NaH 2 PO 2 ·H 2 O 15-25g / L, Na 3 C 6 H 5 O 7 ·H 2 O 100-110g / L, (NH 4 ) 2 SO 4 30-35g / L, pH value is 8.8-9.2, temperature is 90℃; the composition of bath 2 is CrF 3 10-20 g / L, NaH 2 PO 2 ·H 2 O 5-10 g / L, Na 3 C 6 H 5 O 7 ·H 2 O 5-10g / L, CrCl 3 ·6H 2O 1-5 g / L, pH 8-10, mix the two plating solutions and stir well, and place in a water bath thermostat with a temperature of 90 °C. The diamond particles were introduced into the plating solution, plated by ultrasonic and mechanical stirring, and the temperature of the water bath was kept at 90° C. for 1 hour. After cooling, the electroless diamond particles were taken out, washed with water and dried. Mix the diamond particles with the zirconia ball mill to make the diamond partic...

Embodiment 3

[0026] The Ni-P coating is prepared on the diamond surface by chemical plating, the diamond particles are 150-180μm, and the composition of the plating solution includes NiSO 4 ·6H 2 O 20-30g / L, NaAc 40-50 g / L, NaH 2 PO 2 ·H 2 O 30-40 g / L, CH 3 COONH 4 10-20 g / L, a small amount of sulfuric acid, adjust the pH value of the plating solution to 5-6, introduce the diamond particles into the plating solution, apply ultrasonic and mechanical stirring for plating, the water bath temperature is 80 °C, and the time is 1 hour. After cooling, take out the electroless diamond plating Granules, washed with water and dried. Mix the diamond particles with the zirconia ball mill to make the diamond particles completely embedded, then place the mixture in a corundum crucible with a capacity of 500ml to cover, and then place it in a vacuum microwave heating furnace for 20 minutes, with a microwave power of 1.5 KW, sintering temperature 800℃, vacuum degree 1.3×10 -3 Pa, and finally coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com