Preparation method of diamond surface coated Ni-W-P metal plating layer

A technology of surface coating and metallization, which is applied in the field of preparation of Ni-W-P metallization coating on the surface of diamond, can solve the problem that the matrix material has no obvious effect on diamond holding force, and achieve shortening of processing time, effective heat energy, and promotion of speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

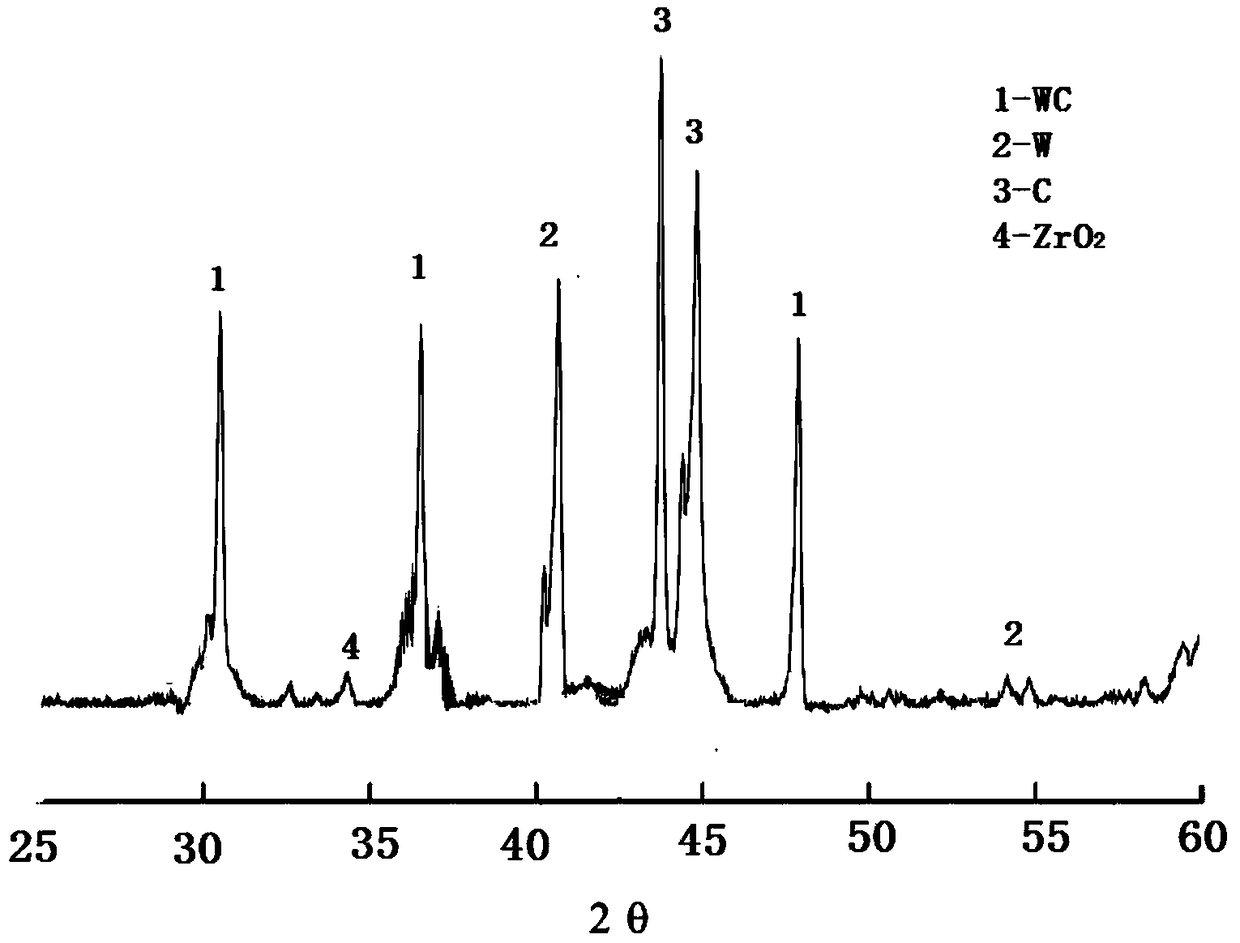

[0020] A preparation method of a diamond surface coated Ni-W-P metallized coating, comprising the steps of:

[0021] S1. Soak diamond particles with an average particle size of 200 μm in a degreasing solution at a temperature of 75° C. for 10 minutes for degreasing. The degreasing solution includes sodium hydroxide 5 g / L, sodium carbonate 20 g / L, sodium phosphate 5 g / L, Sodium sulfite 20g / L, sodium dodecylsulfonate 1g / L; take it out, rinse it with water, put it in a micro-etching solution at a temperature of 70°C for 2 minutes for roughening, and the micro-etching solution includes potassium persulfate 150g / L, copper sulfate pentahydrate 15g / L, concentrated sulfuric acid 5mL / L, take it out, rinse it with water, and then put it in the sensitization-activation solution and stir for 5min for sensitization and activation. The sensitization-activation solution includes palladium chloride 1g / L, tin chloride 5g / L, concentrated hydrochloric acid 50ml / L, sodium chloride 100g / L, take it...

Embodiment 2

[0026] A preparation method of a diamond surface coated Ni-W-P metallized coating, comprising the steps of:

[0027] S1. Soak diamond particles with an average particle size of 500 μm in a degreasing solution at a temperature of 85°C for 8 minutes for degreasing. The degreasing solution includes 15 g / L of sodium hydroxide, 10 g / L of sodium carbonate, and 15 g / L of sodium phosphate , Sodium Sulfite 10g / L, Sodium Dodecyl Sulfonate 5g / L; Take it out, rinse it with water, put it in a micro-etching solution at a temperature of 60°C for 5 minutes for roughening, and the micro-etching solution includes persulfuric acid Potassium 100g / L, copper sulfate pentahydrate 25g / L, concentrated sulfuric acid 1mL / L, take it out, wash it with water, and then put it in the sensitization-activation solution and stir for 10min for sensitization and activation. The sensitization-activation solution includes chloride Palladium 0.5g / L, tin chloride 10g / L, concentrated hydrochloric acid 30ml / L, sodium c...

Embodiment 3

[0031] A preparation method of a diamond surface coated Ni-W-P metallized coating, comprising the steps of:

[0032] S1. After degreasing, roughening, sensitizing, activating and reducing diamond particles with an average particle size of 50 μm, they are added to the chemical plating solution for chemical plating. The chemical plating solution includes: nickel sulfate hexahydrate 15g / L, Sodium hypophosphite 15g / L, sodium tungstate 10g / L, sodium citrate 60g / L, lactic acid 7mL / L, ammonium sulfate 25g / L, o-benzoylsulfonimide 0.8g / L, succinic acid 10g / L, potassium iodide 15mg / L, during the plating process, adjust the temperature of the plating solution to 70°C, the pH value to 9, the stirring rate to 200r / min, and the plating time to 80min. After the plating is completed, let stand, wash, and vacuum dry , to obtain diamond particles coated with Ni-W-P chemical coating on the surface;

[0033] S2, the ZrOCl 2 The stable ZrO was prepared after hydrolysis 2 Sol, with ZrO 2 The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com