Corrosion control method for annular space tubing and casings of oil field water injection well

An annular space and corrosion control technology, used in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve problems such as corrosion and perforation of water injection well tubing, inability to inject sewage, and casing strength reduction, and achieve control The reproduction of bacteria and the corrosion of the medium, the protection from corrosion, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

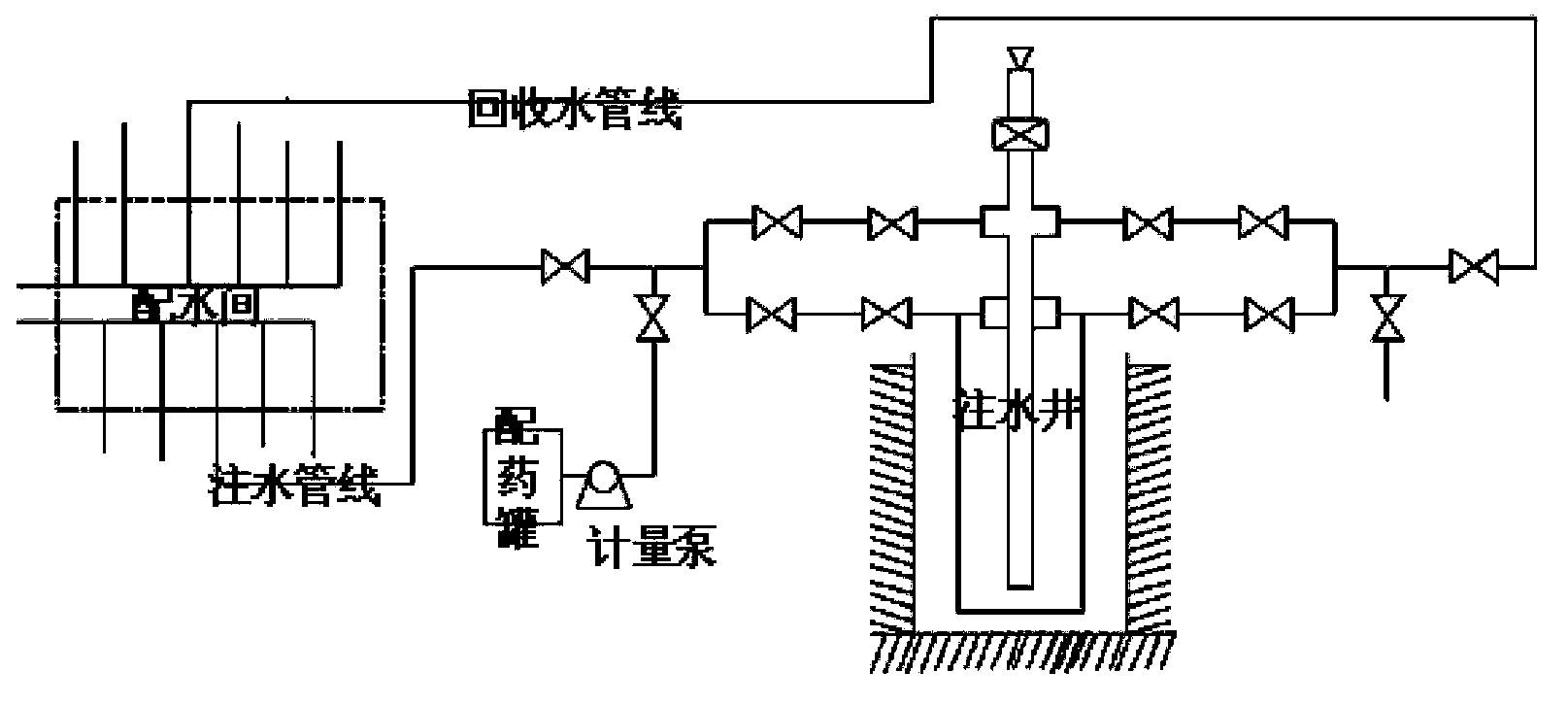

[0021] This embodiment is a water injection well (well depth 2200m) with recovery water pipeline.

[0022] The construction process of this embodiment, the steps are: the connection process shown in Figure 1, the original water injection process at the wellhead of the water injection well is adjusted to the backwashing well process, the recovery water single well pipeline valve in the water distribution room is opened, and the well flushing displacement is adjusted to 25m 3 / h, after 1.5 hours of well flushing, reduce the flushing displacement to 10m 3 / h, start the high-pressure plunger metering pump to match the displacement of well flushing water, and add the A agent formula, add the mass concentration as 25%, and add the time for 2.1 hours, then reduce the plunger pump displacement to make the A agent add the mass concentration as 5%, the addition time is 4 hours, stop the plunger pump dosing, increase the flushing water discharge to 25m 3 / h, after 1.56 hours of well flu...

Embodiment 2

[0027] This embodiment is a water injection well (well depth 1800m) with a recovery water pipeline.

[0028] The construction process of this embodiment, the steps are: the connection process shown in Figure 1, the original water injection process at the wellhead of the water injection well is adjusted to the backwashing well process, the recovery water single well pipeline valve in the water distribution room is opened, and the well flushing displacement is adjusted to 25m 3 / h, after 1.5 hours of well flushing, reduce the flushing displacement to 10m 3 / h, start the high-pressure plunger metering pump to match the displacement of well-washing water, and add the A agent formula, add the mass concentration to be 25%, and the addition time is 1.72 hours, then reduce the plunger pump displacement to make the A agent add the mass concentration to be 5%, the addition time is 4 hours, stop the plunger pump dosing, increase the flushing water discharge to 25m 3 / h, after 1.36 hours...

Embodiment 3

[0033] This embodiment is a water injection well (well depth 2480m) with recovery water pipeline.

[0034] The construction process of this embodiment, the steps are: the connection process shown in Figure 1, the original water injection process at the wellhead of the water injection well is adjusted to the backwashing well process, the recovery water single well pipeline valve in the water distribution room is opened, and the well flushing displacement is adjusted to 25m 3 / h, after 1.5 hours of well flushing, reduce the flushing displacement to 10m 3 / h, start the high-pressure plunger metering pump to match the displacement of well flushing water, and add the A agent formula, add the mass concentration to be 25%, and the addition time is 2.4 hours, then reduce the plunger pump displacement to make the A agent add the mass concentration as 5%, the addition time is 4 hours, stop the plunger pump dosing, increase the flushing water discharge to 25m 3 / h, after 1.7 hours of we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com