Hydraulic double-pump confluence control device and all-terrain crane

A double-pump confluence and control device technology, which is applied to cranes, fluid pressure actuators, mechanical equipment, etc., can solve problems such as low reliability, poor interchangeability, and bulkiness, and achieve small spool diameters and reduced flow rates , the effect of less power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further detail below with reference to the drawings and embodiments.

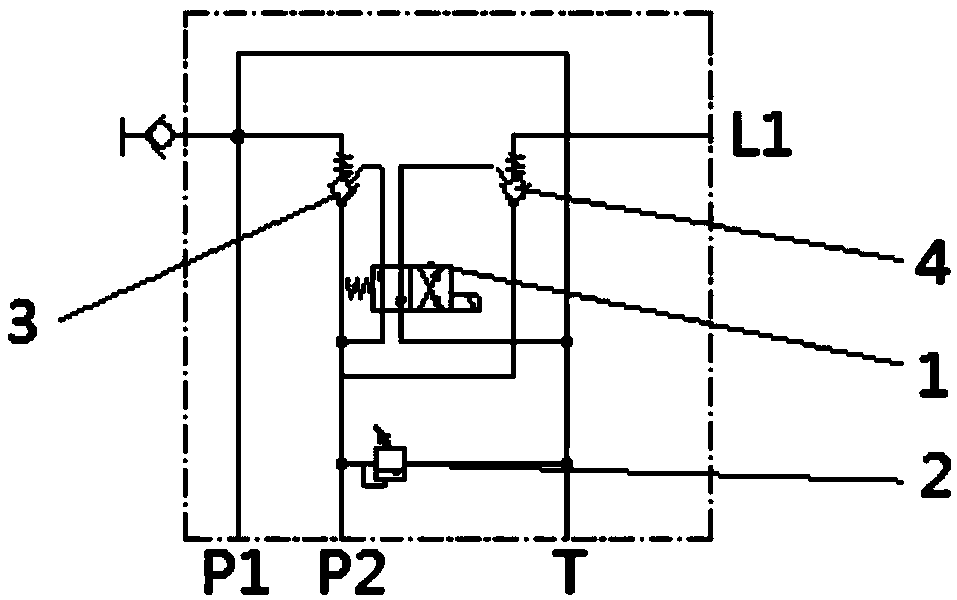

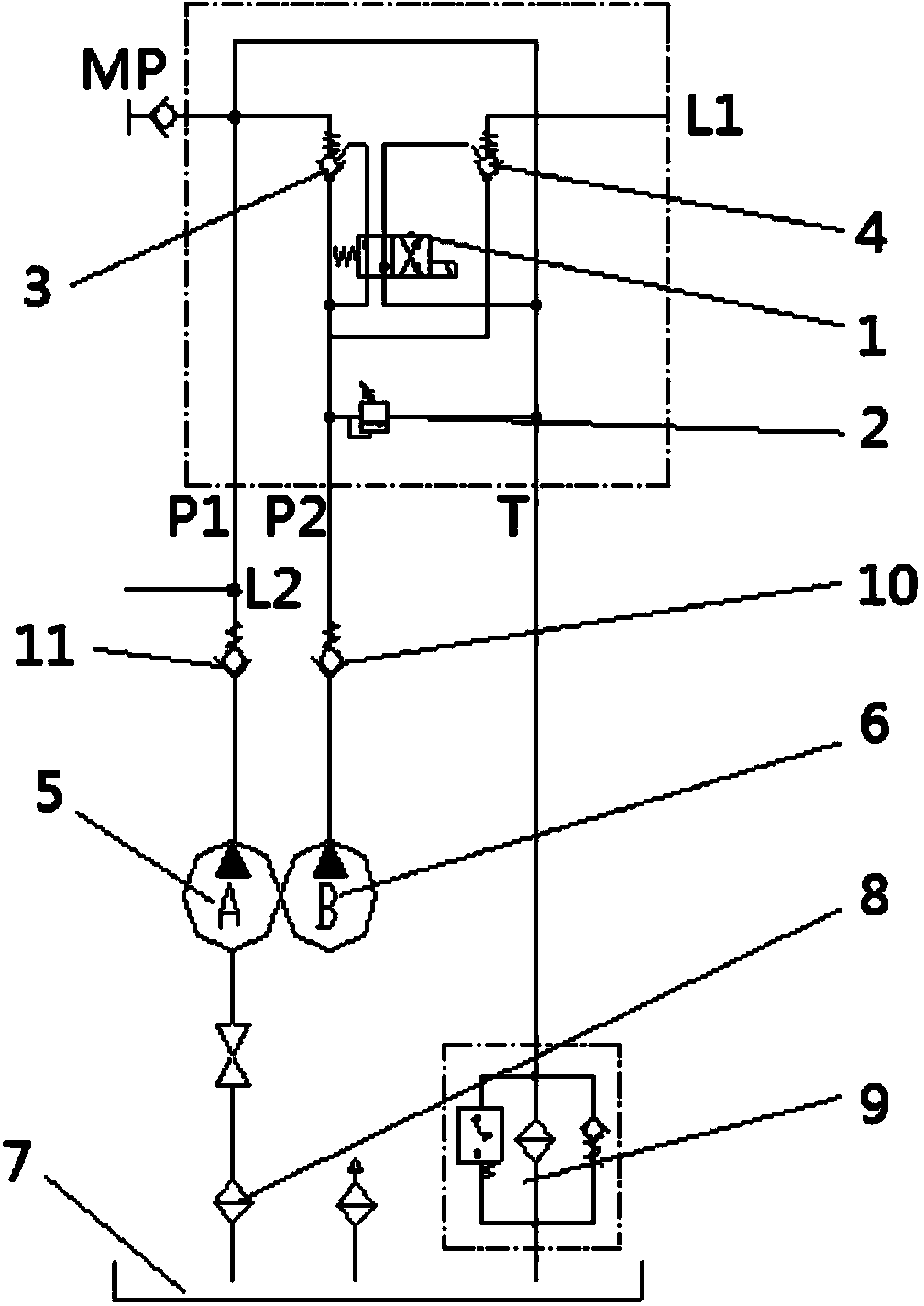

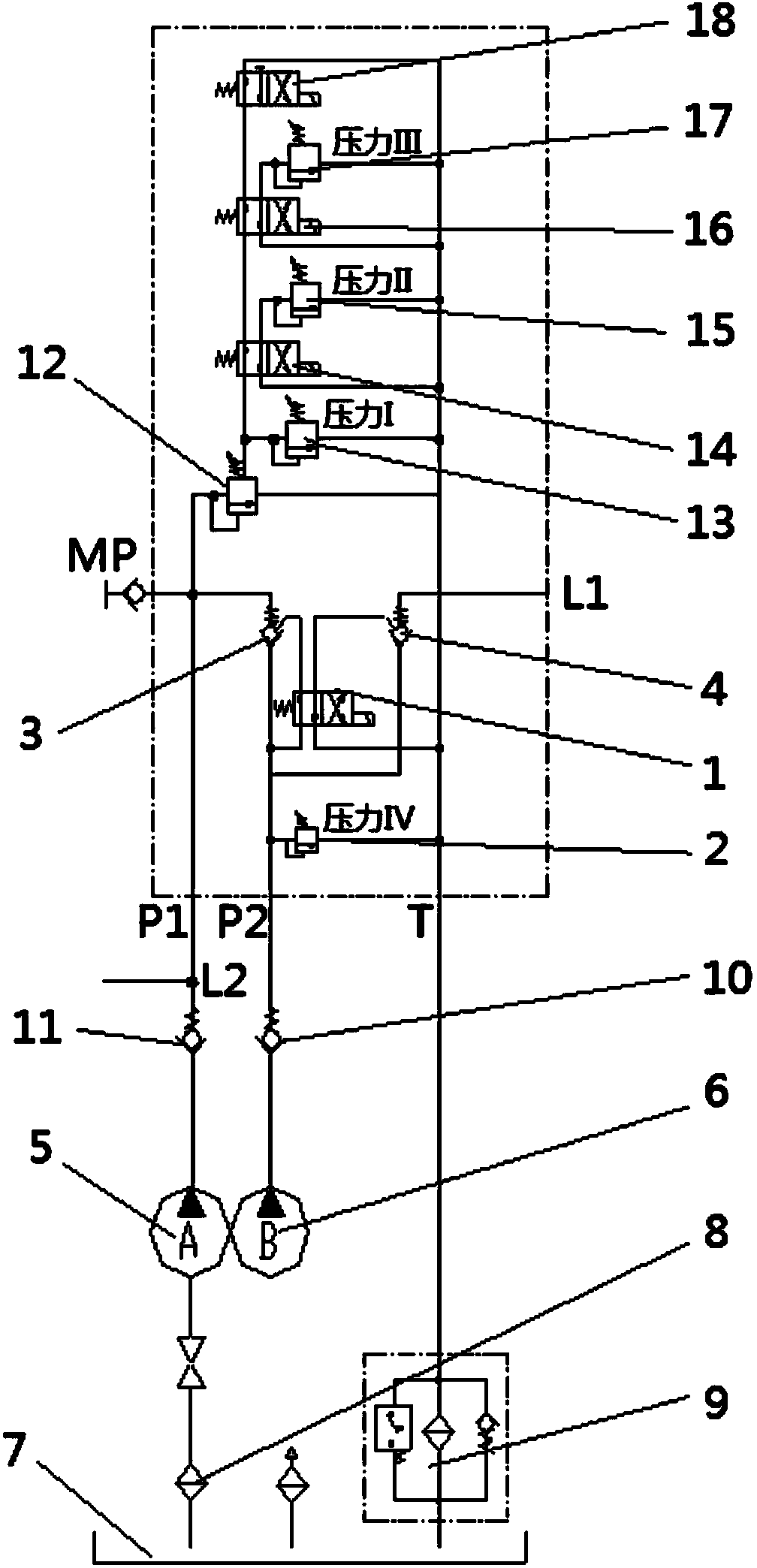

[0026] Such as figure 1 As shown, it is a schematic diagram of the hydraulic principle of an embodiment of the hydraulic double-pump confluence control device of the present invention. In this embodiment, the hydraulic dual-pump confluence control device includes a confluence solenoid valve 1 , a main overflow valve 2 , a first pilot-closed hydraulic control check valve 3 and a second pilot-close hydraulic control check valve 4 . These valve parts can be arranged in the same valve block, or can be arranged in a combined valve block etc. as required.

[0027] The oil inlet and oil outlet of the main relief valve 2 respectively pass through figure 1 The P2 oil port and the T oil port on the middle valve block communicate with the second oil pump B with a relatively small flow rate and the oil tank T, and are mainly used to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com