Weak X-ray 3D (three-dimensional) imaging method

An imaging method and 3D technology, applied in the direction of using radiation for material analysis, can solve problems such as low resolution, and achieve the effect of wide application fields, speed improvement, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

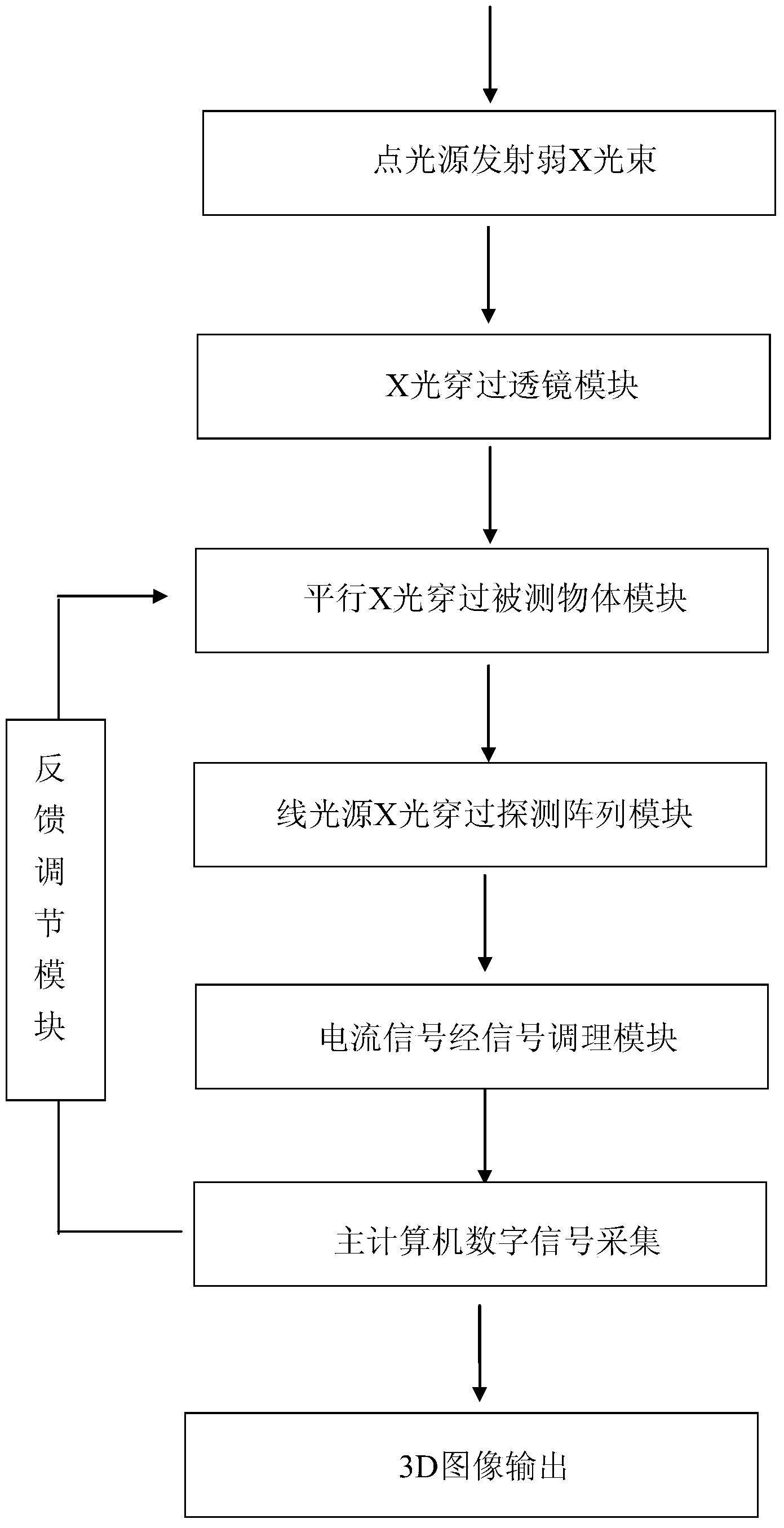

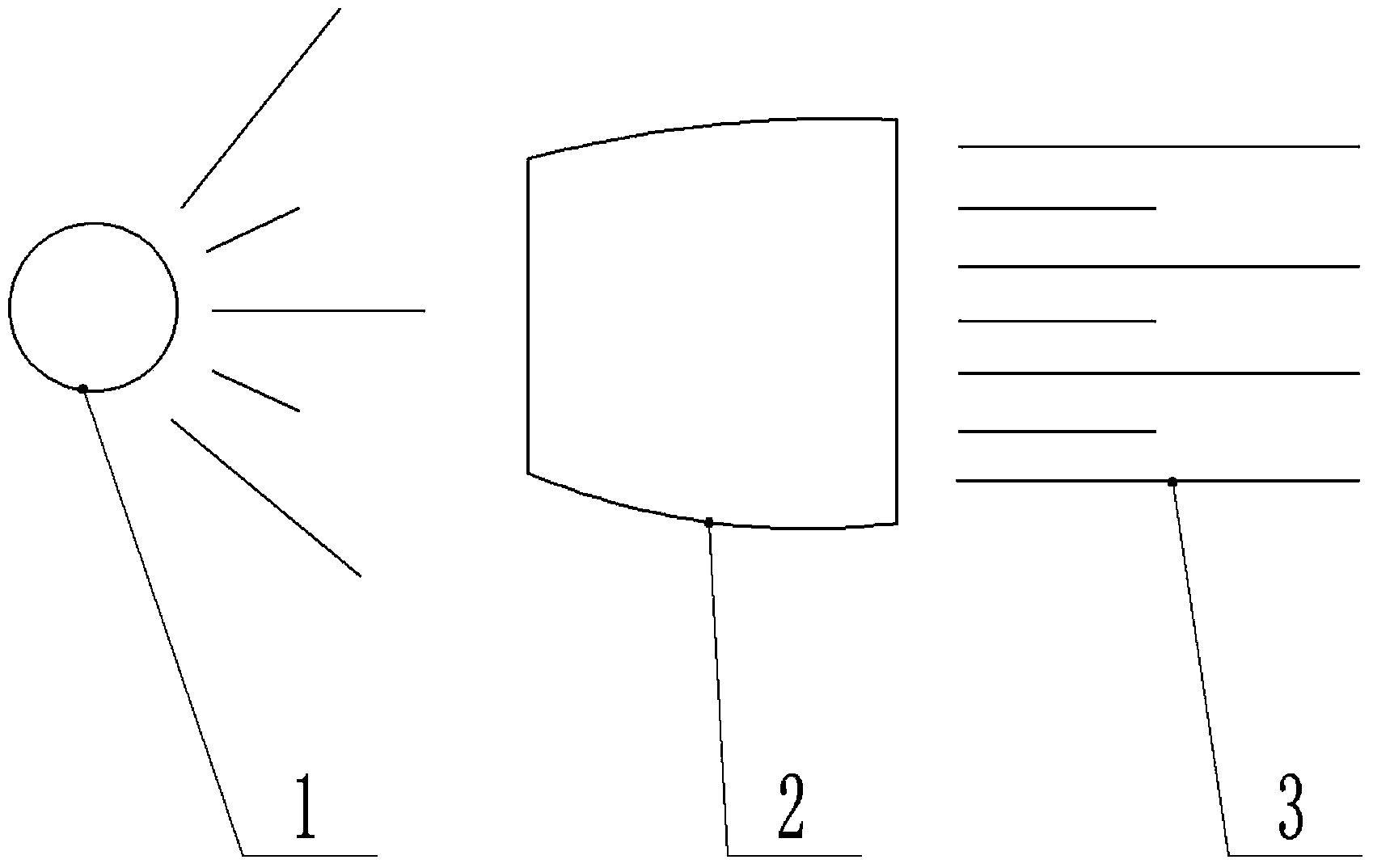

[0036] Embodiment 1: The working principle of the lens module is as follows figure 2 shown. The module is mainly composed of weak X-ray point light source 1, X-ray lens device 2 and parallel X-ray 3. Wherein the energy of the X-ray point light source 1 is below 100KeV, which is a weak X-ray. The X-ray lens device 2 is composed of a parallel-beam X-ray lens with a semi-lens structure. Its function is to convert the scattered X-rays into parallel-beam X-rays. When the weak X-ray from the X-ray point source 1 enters the X-ray lens device , the weak X-ray propagates inside the lens, part of it is absorbed by the lens wall, and the remaining part is transmitted in parallel by the inner track of the lens to form parallel X-ray 3 .

Embodiment 2

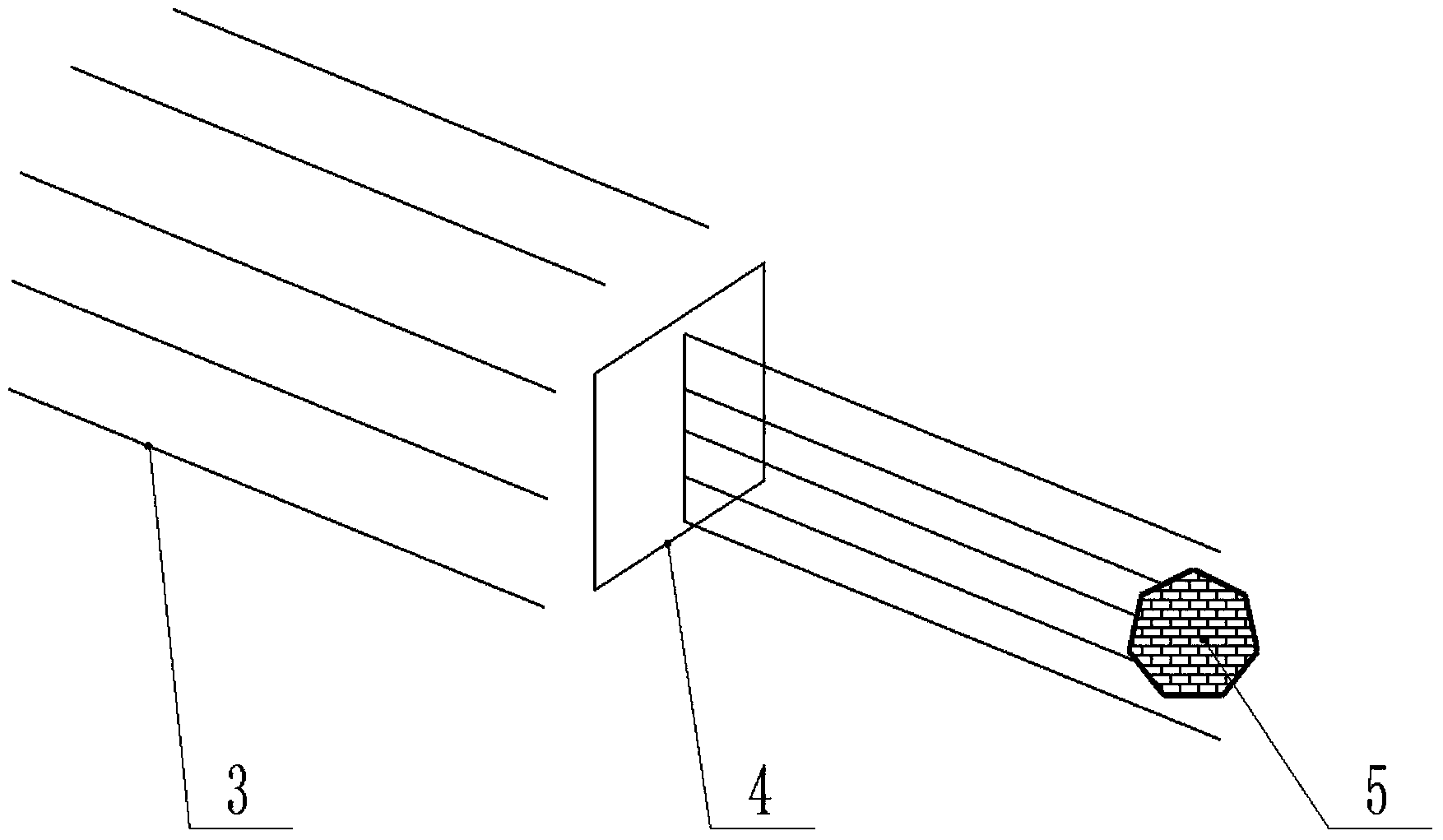

[0037] Embodiment 2: The working principle of the measured object module is as follows image 3 shown. The module is mainly composed of parallel X-rays 3 , long slit lead plates 4 and objects to be measured 5 . The parallel X-ray 3 that comes out from embodiment one enters in the long slit lead plate 4, and the lead material can shield X-ray, and there is a slit in the middle of the long slit lead plate 4, and the width between the slits is greater than the X-ray wavelength. It can ensure that X-rays can be converted into line light sources without diffraction. The X-ray passes through the slit to form a line X-ray, which penetrates the object to be measured 5 and is received by the detection array module to form a line X-ray source 6 containing tomographic image information. In the case where the length of the slit is long enough, the object to be measured 5 can scan the entire object only by parallel movement of the workbench where the object to be measured 5 is located du...

Embodiment 3

[0038] Embodiment 3: The working principle of the detector array module is as follows Figure 4 shown. The module is mainly composed of an X-ray light source 6 , a scintillator 7 and a photodiode 8 . The X-ray light source 6 enters the scintillator 7 to excite the atoms or molecules, and the excited atoms or molecules emit light during the de-excitation process, and convert the X-rays with a very short wavelength into fluorescence. The fluorescence has a long wavelength, so it is easy to be detected. Photodiode 8 receives. The photons pass through the scintillator 7 and reach the photodiode 8, where they are converted into current signals.

[0039] A weak X-ray 3D imaging method of the present invention, the current signal generated after passing through the detector array module is an extremely weak current analog signal, the signal passes through the signal conditioning module, and the current signal is converted into a voltage signal by the signal conditioning circuit, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com