Grid-control cold cathode X-ray tube

An X-ray tube and cold cathode technology, which is applied in the field of X-ray tubes, can solve the problems of complex ray tube assembly process, many electrons intercepted by the grid, and difficulty in realizing a small focus, and achieves low cost, small focus, and prevention of inter-electrode strikes. fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

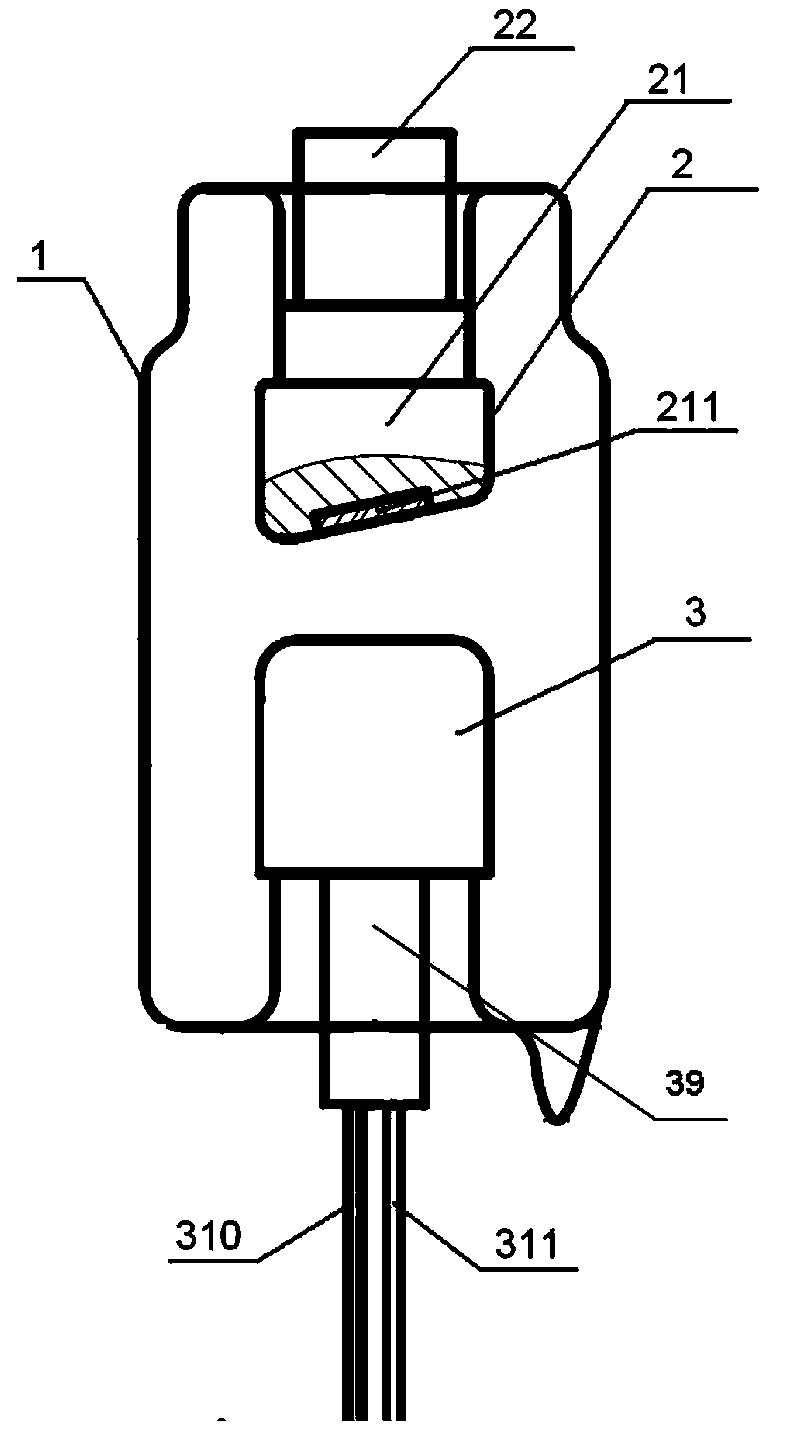

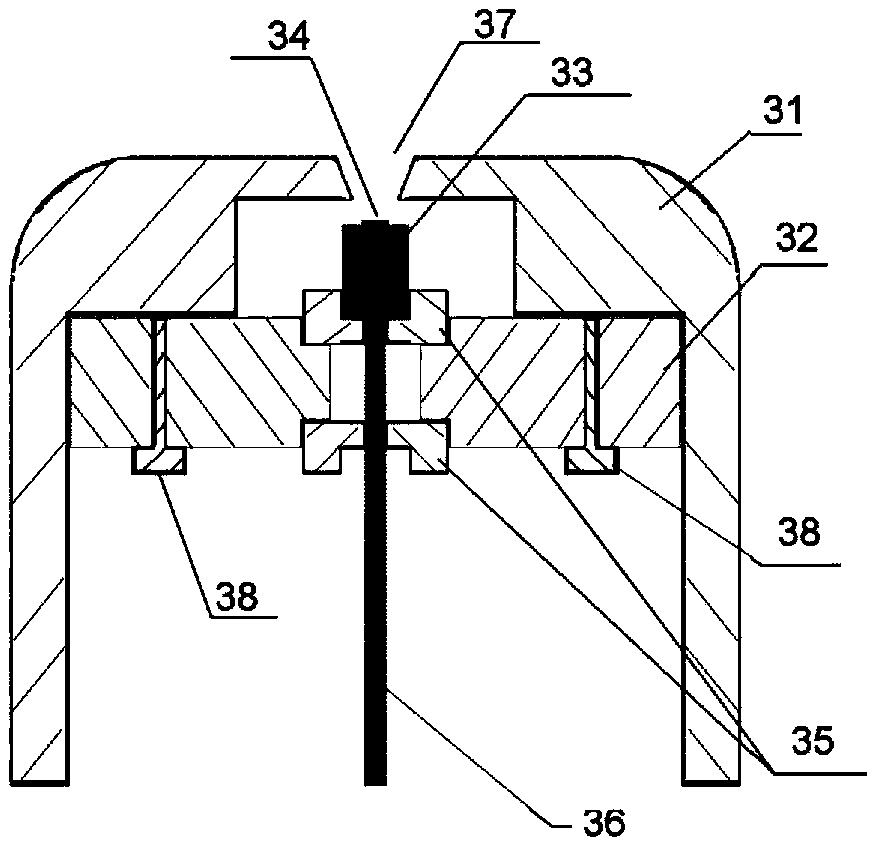

[0033] The gate-controllable cold-cathode X-ray tube of the present invention utilizes the excellent electron emission performance of the cold cathode, and packages it in a vacuum container as a part of the cathode assembly. The high electric field formed by the gate voltage on the surface of the cold cathode field emitter excites the electron beam from the inside of the emitter. A voltage of 0-3000V is applied between the grid substrate and the emitter electrode to excite electrons from the cold cathode emitter.

[0034] In the grid-controllable cold cathode X-ray tube, the high voltage is introduced through the anode connection column, the cathode cover can be used as a grid control electrode, and is connected to a grid lead-out electrode, the cathode base is connected to the cathode connection rod, and connected to the cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com