Light reflecting thin film of photovoltaic module and method for fixing light reflecting thin film and soldering strip

A photovoltaic module and fixing method technology, applied in photovoltaic power generation, electrical components, semiconductor devices and other directions, can solve the problems of low product quality rate, reduced cost of reflective tape, complicated process, etc., and achieve simple and flexible fixing steps, low cost, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

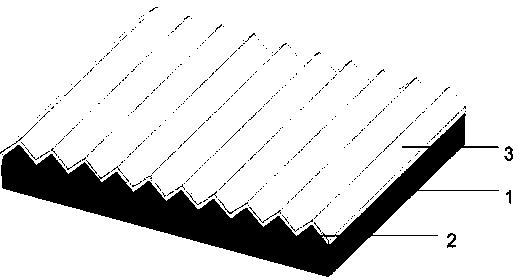

[0043] Example of the preparation method of the reflective film: 1) Prepare a 100um thick PET substrate 1, 2) Coat the acrylic liquid on the PET surface, 3) Cover the PET surface with a sawtooth molding mold, fill the acrylic liquid into the grinding In the saw-toothed cavity, 4) Use ultraviolet light to instantly solidify the acrylic to form a triangular reflective prism 2, 5) Load the film substrate forming the reflective prism into the vacuum evaporation machine, with the saw-toothed surface facing the crucible, 6) Put the film substrate with a purity greater than 99.99% high-purity aluminum is loaded into the crucible, 7) vacuumize with a vacuum pump to make the vacuum in the evaporation chamber reach 1.3*10 -2 to 1.3*10 -3 Pa, 8) Heating the crucible to melt the high-purity aluminum wire at 1200°C to 1400°C and evaporate it into gaseous aluminum, 9) Control the moving speed of the film substrate at 300mm / min to 1000mm / min, and control the evaporation time at 1 to 1 5 min...

Embodiment 2

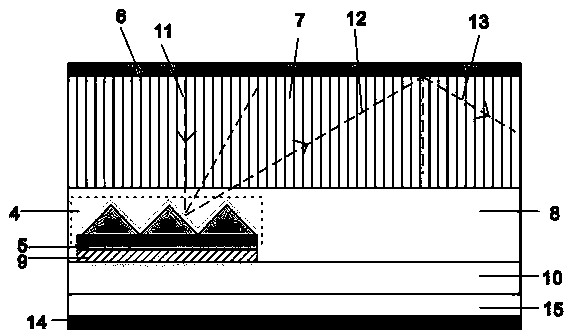

[0046] Example of using the reflective film: 1) Prepare the cells and carry out test classification; 2) Solder one end of the soldering tape to the main grid on the upper surface of the cells at a temperature of 350°C; The reflective film is laid flat on the welding strip on the upper surface of the cell, 4) The position of the reflective film is fixed with a transparent adhesive film, 5) The other end of the welding strip is welded to the main grid on the lower surface of the adjacent cell, 6) Spread a layer of EVA8 (ethylene-vinyl acetate copolymer) on the glass 7, and then spread the welded battery sheet 10, 7) connect the internal circuit of the component, 8) spread another layer of EVA15 and Component backplane 14, 9) Send the laminated components into the laminator, heat the temperature to 142°C for 20 to 30 minutes, 10) carry out the follow-up process of the laminated component according to the conventional method and complete Preparation of components.

[0047] The ou...

Embodiment 3

[0049] Example of how to use the reflective film: 1) Prepare the cells and carry out test binning, 2) Solder one end of the soldering tape to the main grid on the upper surface of the cell at a temperature of 350°C, 3) Lay the components on a flat surface In the glass 7, spread a layer of EVA8 (ethylene-vinyl acetate copolymer) on the glass 7, and then spread the welded battery sheet 10, 4) connect the internal circuit of the component, 8) spread the battery on the battery sheet Another layer of EVA15 and module backplane 14, 5) Paste the luminescent film of the present invention on the area of the module backplane without cells, where the base angles of the prisms are 90 degrees and 30 degrees in the area around the module without cells , and the 30-degree angle is close to the inside of the component. The reflective film in the area between the cell and the cell has a prism bottom angle of 30 degrees. 6) After the stack is completed, each component is sent to the laminator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com