DFIG direct current grid-connected power generation system based on RMC and torque control method of DFIG direct current grid-connected power generation system

A torque control and grid-connected power generation technology, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problems of many converter conversion stages, difficult control, and reduced system reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to describe the present invention more specifically, the technical solution and its control method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

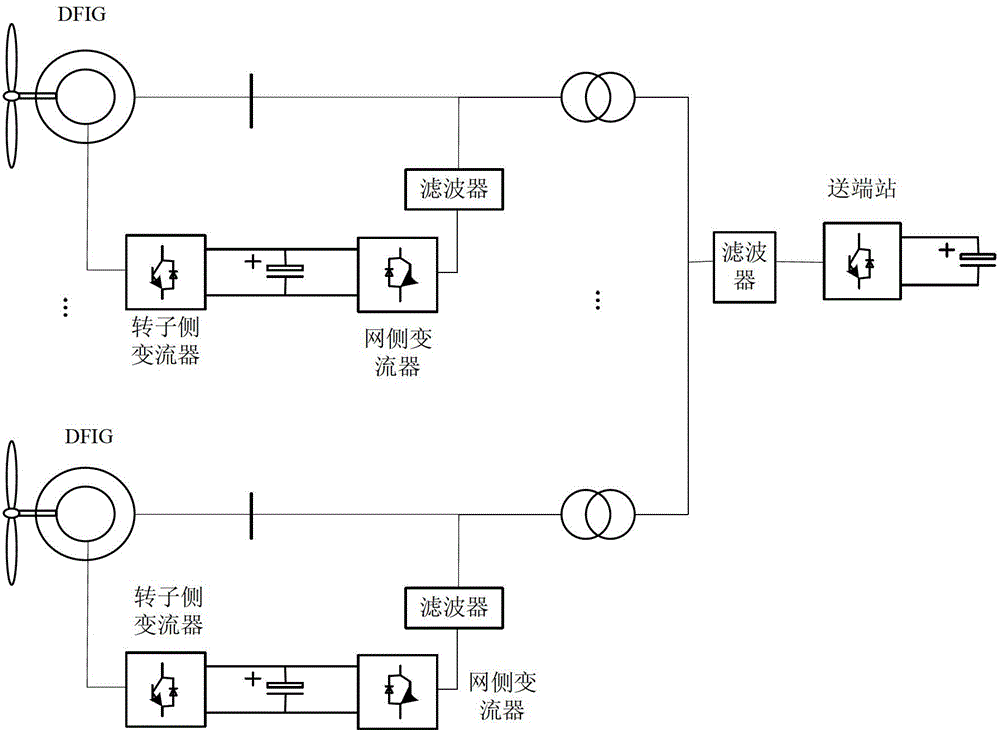

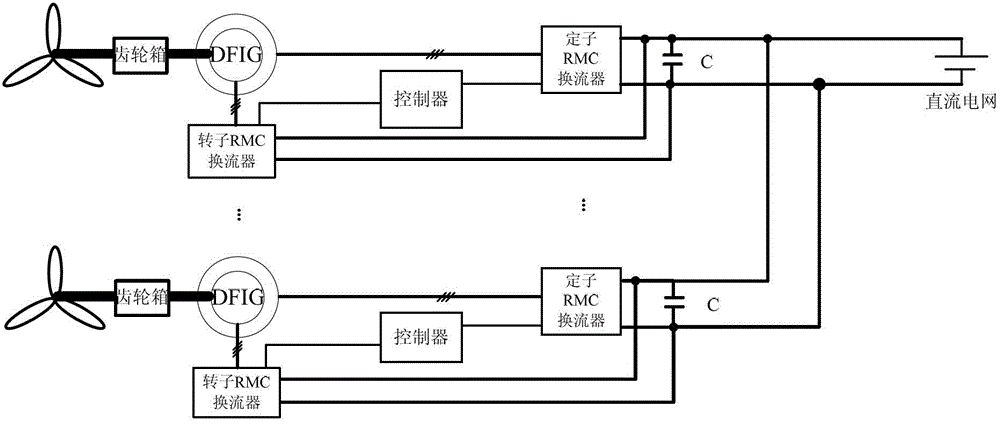

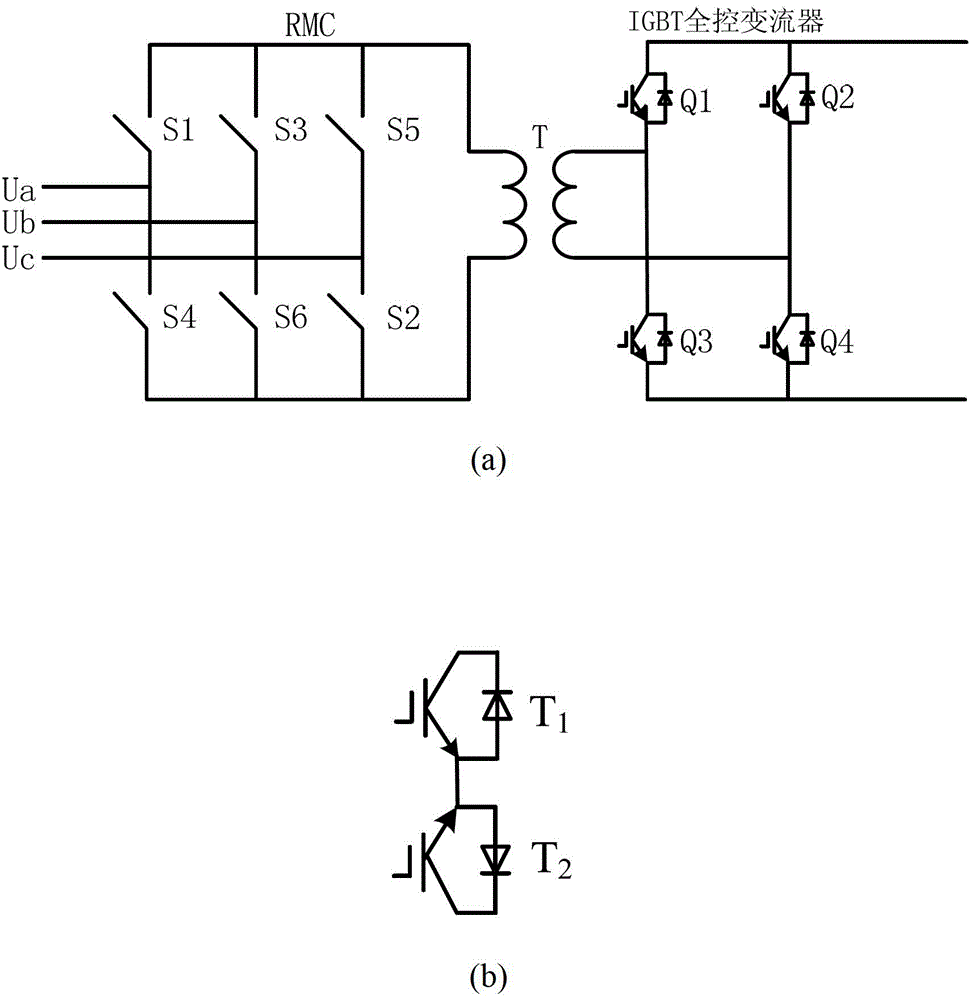

[0082] like figure 2 As shown, an RMC-based DFIG DC grid-connected power generation system includes multiple DFIGs and high-voltage DC grids. Each DFIG is connected with a stator RMC converter and a rotor RMC converter; a stator RMC converter and a rotor RMC converter There is a controller connected to the converters; DFIG has three-phase stator windings and three-phase rotor windings, and the three-phase stator windings and three-phase rotor windings are all connected in a star connection; where:

[0083] The stator RMC converter is used to convert the DC voltage on the high-voltage DC grid into a positive and negative alternating square wave voltage during the start-up phase of DFIG, and step down the square wave voltage, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com