A method of producing macaroni using rice

A technology for macaroni and rice protein powder, which is applied in the field of rice product processing, can solve the problems of no bite force, coarse grain feeling, high pulping rate, difficult to cut and shape, etc., and achieves the effect of improving insufficient nutritional function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

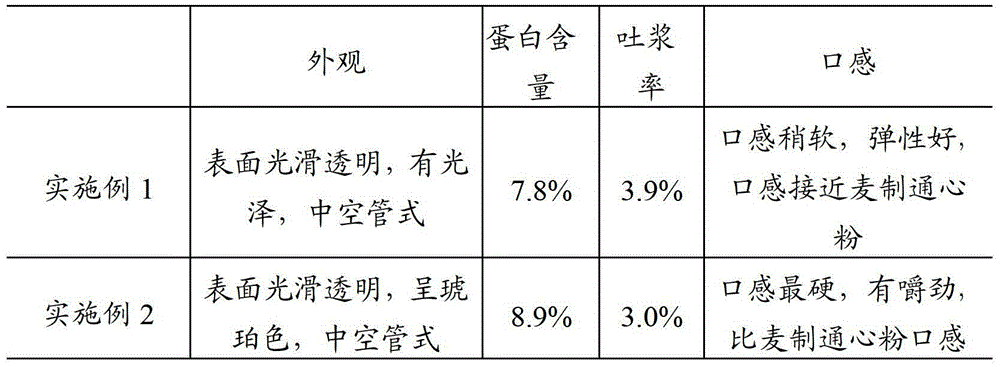

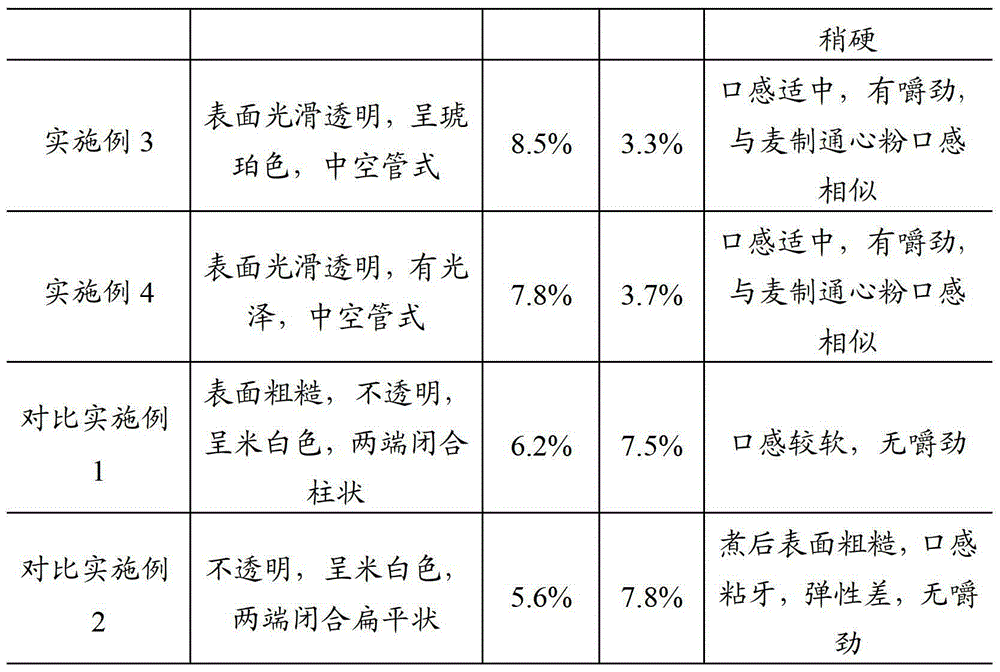

Examples

Embodiment 1

[0107] Embodiment 1: Adopt the method of the present invention to prepare high-protein rice macaroni

[0108] The implementation steps of this embodiment are as follows:

[0109] A. Rice raw material pretreatment

[0110] Early indica rice and late indica rice sold by Jiangxi Jinnong Rice Industry Group Co., Ltd. were used. Remove the denatured rice grains in the early indica rice and the late indica rice, and then use the desander machine sold by Jiangsu Muyang Group to remove impurities such as sand, stones, and metals. Indica rice mixed, its weight 200kg (protein content 6.4%, water content 13.6%), then use the rice washing machine sold by Quanzhou Bosida Food Machinery Manufacturing Co., Ltd. to wash with water to remove floating debris, and then wash the rice at room temperature Soak in water for 6 hours according to the weight ratio of washed rice and water of 1:1 under the conditions, and then filter and separate to obtain the soaked rice material;

[0111] B. smash ...

Embodiment 2

[0133] Embodiment 2: Adopt the method of the present invention to prepare high-protein rice macaroni

[0134] The implementation steps of this embodiment are as follows:

[0135] A. Rice raw material pretreatment

[0136] Early indica rice and late indica rice sold by Jiangxi Huiyin Rice Industry Co., Ltd. were used. Remove the denatured rice grains in the early indica rice and late indica rice, and then use the desander machine sold by Jining Hongkun Machinery Manufacturing Co., Ltd. to remove impurities such as sand, stones, and metals. The weight ratio of early indica rice to late indica rice is 1:0.67. Mix early indica rice with late indica rice, the weight is 300kg (protein content 6.0%, water content 13.3%), then use the rice washing machine sold by Zhejiang Xiangying Central Kitchen Equipment Co., Ltd. to wash with water, remove floating debris, and wash The rice is then soaked in water for 12 hours according to the weight ratio of washed rice and water of 1:0.8 at ro...

Embodiment 3

[0155] Embodiment 3: Adopt the method of the present invention to prepare high-protein rice macaroni

[0156] The implementation steps of this embodiment are as follows:

[0157] A. Rice raw material pretreatment

[0158] Early indica rice and late indica rice sold by Jiangxi Shengniu Rice Industry Co., Ltd. were used. Remove the denatured rice grains in the early indica rice and late indica rice, and then use the desander machine sold by Shixing County Baicheng Grain and Oil Machinery Manufacturing Co., Ltd. to remove sand, stone, metal and other impurities. Said early indica rice is mixed with late indica rice, its weight is 300kg (protein content 5.8%, water content 13.0%), then use the rice washing machine sold by Nanchang City Haotian Grain and Oil Engineering Service Department to wash with water, remove floating debris, wash The cleaned rice is then soaked in water for 8 hours according to the weight ratio of washed rice and water of 1:1.2 at room temperature, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com