Solid carbon dioxide absorbent and elimination and concentration method of carbon dioxide using the absorbent

A solid carbon dioxide and carbon dioxide technology, applied in chemical instruments and methods, through absorption, separation methods, etc., can solve the problems of by-products, reaction tower pressure drop, low economy, etc., and achieve the effect of stable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: take X-type zeolite as the K-containing 2 CO 3 manufacture of absorbent

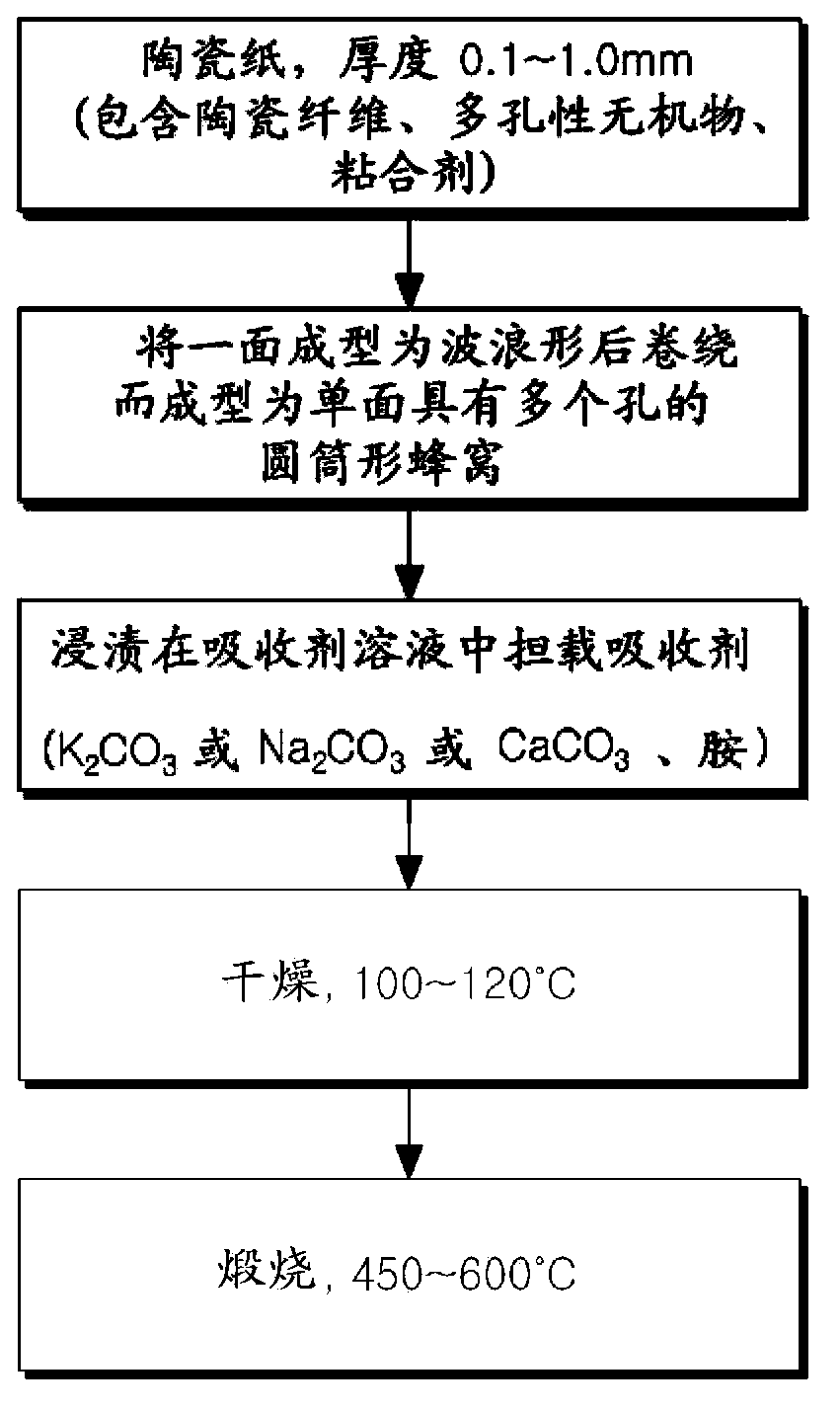

[0045] Manufactured containing 50% ceramic fiber, 35% X-type zeolite, 3% PVA as an organic binder, 5% cellulose, 5% sepiolite as an inorganic binder, 2% silica powder and a thickness of 0.21 mm of ceramic paper that can be used at high temperatures above 100°C. Using two sheets of ceramic paper, one of them was molded into a wave shape with a pitch of 3.8 mm and a height of 1.8 mm to produce a single-sided corrugated molded product in the form of corrugated paper. This single-face corrugated molded body was wound to form a cylindrical honeycomb with a diameter of 6 cm and a length of 40 cm, and then dried at 110° C. for 5 hours. Immerse the dried honeycomb in 30% K 2 CO 3 After remaining in the solution for 10 minutes, it was taken out, dehydrated at room temperature, and then dried at 150° C. for 24 hours. will load K 2 CO 3 The post-dried honeycombs were kept at 400°C for 2...

Embodiment 2

[0046] Embodiment 2: with gamma alumina as the K-containing 2 CO 3 manufacture of absorbent

[0047] Manufactured containing 50% ceramic fiber, 35% gamma alumina, 3% PVA as organic binder, 5% cellulose, 5% sepiolite as inorganic binder, 2% silica powder and a thickness of 0.21mm ceramic paper that can be used at high temperatures above 100°C. Subsequent steps were carried out in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com