High temperature resistant and degradable polylactic acid wood plastic material and preparation method thereof

A technology of wood-plastic materials and polylactic acid, which is applied in the fields of biodegradable polymer materials, polymer molding processing, and polymer blending, can solve the problems of low heat resistance, high production cost, and low tear strength, and achieve improved Effects of impact strength, heat resistance improvement, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

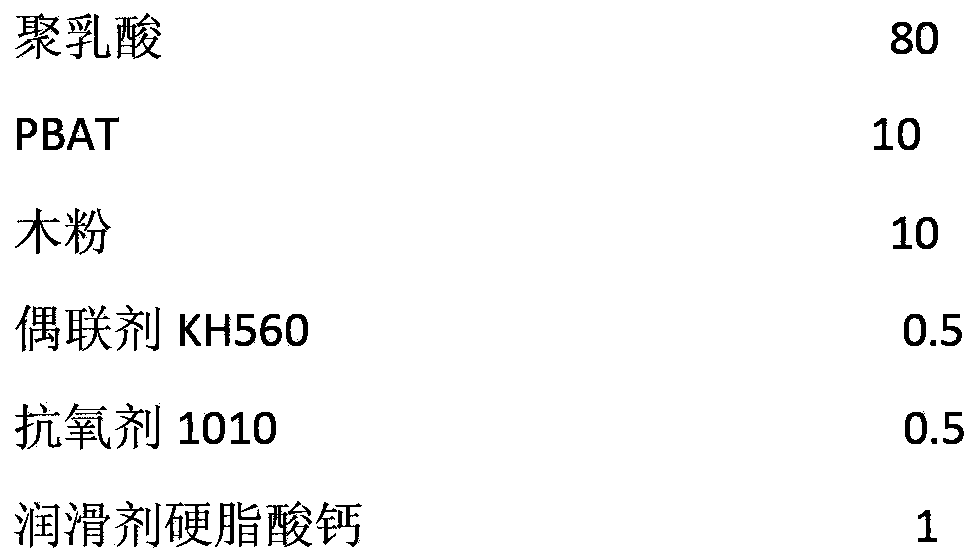

Embodiment 1

[0033] The material provided by the present invention is formed by the proportioning of following raw materials by weight:

[0034]

[0035] First, dry the polylactic acid and PBAT of the above-mentioned raw materials in a vacuum oven at 80°C for 8 hours, and dry the wood powder in a blast drying oven at 100°C for 4 hours; the polylactic acid and PBAT are mechanically mixed according to the proportion, and then sprayed with a coupling agent. Add wood powder and other additives and mix again, so that polylactic acid and PBAT particles can be coated with a layer of wood powder, and then use an extruder to prepare blended masterbatches, set the temperature of the extruder at 160°C-200°C, From the feeding section to the machine head, the temperature is gradually increased, the feeding screw speed is 25rpm, the main screw speed is 60rpm, and the cutting length is 4mm; the masterbatch is then injected into a standard spline by the injection molding machine, and the temperature of ...

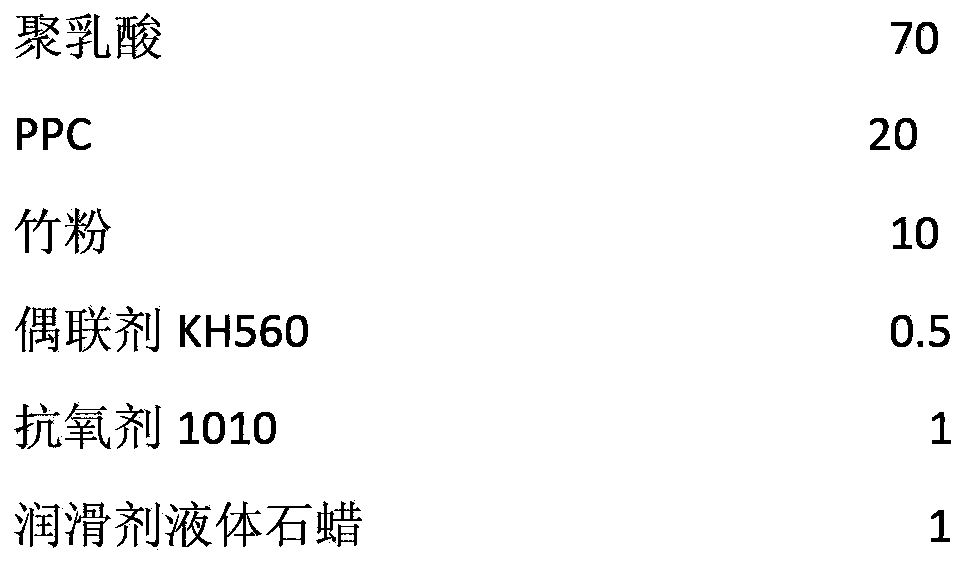

Embodiment 2

[0037] The material provided by the present invention is formed by the proportioning of following raw materials by weight:

[0038]

[0039] First, dry the polylactic acid and PPC of the above raw materials in a vacuum oven at 80°C for 8 hours, and dry the bamboo powder in a blast drying oven at 100°C for 4 hours; the polylactic acid and PPC are mechanically mixed according to the proportion, and then sprayed with a coupling agent. Bamboo powder and other additives are added and mixed again, so that polylactic acid and PPC particles can be coated with a layer of bamboo powder, and then the blending masterbatch is prepared using an extruder, and the temperature of the extruder is set at 160°C-200°C from The temperature from the feed section to the machine head is gradually increased, the feed screw speed is 15rpm, the main screw speed is 140rpm, and the cutting length is 2; the masterbatch is then injected into a standard spline by the injection molding machine, and the tempe...

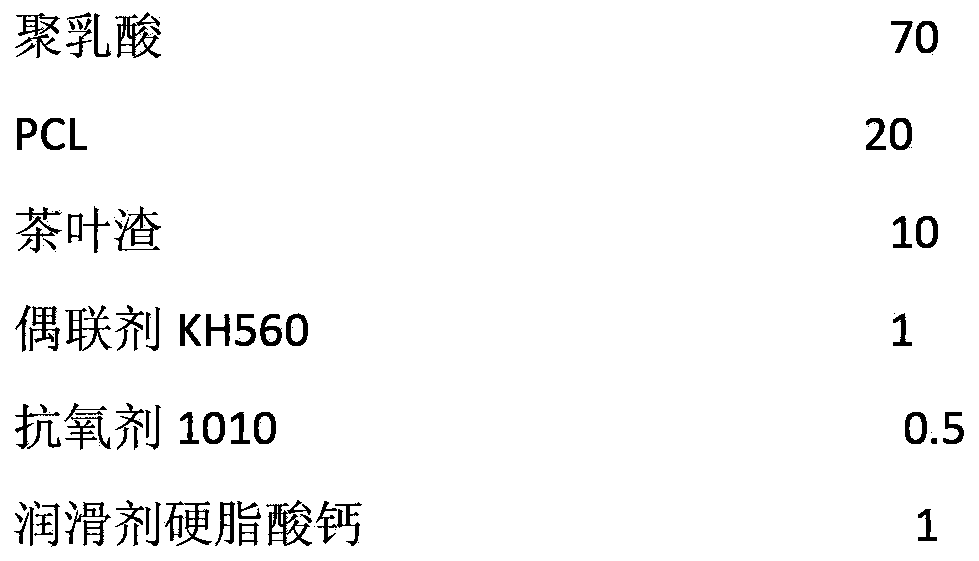

Embodiment 3

[0041] The material provided by the present invention is formed by the proportioning of following raw materials by weight:

[0042]

[0043] First, dry the polylactic acid and PCL of the above raw materials in a vacuum oven at 80°C for 8 hours, and dry the tea leaves in a blast drying oven at 100°C for 4 hours; the polylactic acid and PCL are mechanically mixed according to the proportion, and then sprayed with a coupling agent. After adding tea leaves and other additives, mix again so that polylactic acid and PCL particles can be coated with a layer of tea leaves, and then use an extruder to prepare blended masterbatches. Set the temperature of the extruder at 160°C-200°C. From the feeding section to the machine head, the temperature is gradually increased, the feeding screw speed is 20rpm, the main screw speed is 150rpm, and the cutting length is 2mm; the masterbatch is then injected into a standard spline by the injection molding machine, and the temperature of the injectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Izod notched impact strength | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com