Method for processing cider wine containing more ester

A technology of substance content and processing method, which is applied in the field of cider processing, can solve problems such as insufficient ester aroma, achieve the effects of retaining aroma, increasing ester aroma, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Utilize Saccharomyces cerevisiae CICC1750 (preserved in China Industrial Microorganism Culture Collection Management Center) to ferment and produce cider, the steps are as follows:

[0056] (1) Activation culture of strains: take the strains preserved on the slant and carry out streak culture on the YPD plate medium, the culture temperature is 24-30°C, and the culture time is 24h;

[0057] (2) Liquid culture: pick two rings of yeast strains that have been activated for 24 hours and inoculate them into YPD liquid medium. The culture conditions are: 24-30°C, 24 hours, 120rpm;

[0058](3) Cultivation of fermented seed liquid: absorb the seed liquid cultivated in YPD liquid medium and add it into a 500ml Erlenmeyer flask containing 400ml apple juice for expansion to obtain fermented seed liquid. The culture conditions are: 24-30°C, 24h, 120rpm, the soluble solids content of the apple juice used in this embodiment is 20~22 °;

[0059] (4) Fermentation of cider: put 400ml ap...

Embodiment 2

[0062] Utilize Saccharomyces cerevisiae CICC1845 (preserved in China Industrial Microorganism Strain Preservation Management Center) to ferment and produce cider, the steps are as follows:

[0063] (1) Activation culture of strains: take the strains preserved on the slant and carry out streak culture on the YPD plate medium, the culture temperature is 24-30°C, and the culture time is 24h;

[0064] (2) Liquid culture: pick two rings of yeast strains activated for 24 hours and inoculate them into YPD liquid medium, the culture conditions are: 24-30°C, 24h, 120rpm;

[0065] (3) Cultivation of fermented seed liquid: absorb the seed liquid cultivated in YPD liquid medium and add it into a 500ml Erlenmeyer flask containing 400ml apple juice for expansion to obtain fermented seed liquid. The culture conditions are: 24-30°C, 24h, 120rpm; the soluble solid content of the apple juice used in this embodiment is 22-24. ;

[0066] (4) Fermentation of cider: put 400ml of apple juice in a ...

Embodiment 3

[0069] Utilize Saccharomyces cerevisiae WLS21 strain to ferment and produce cider; The steps are as follows:

[0070] (1) Activation culture of strains: take the strains preserved on the slant and carry out streak culture on the YPD plate medium, the culture temperature is 24-30°C, and the culture time is 24h;

[0071] (2) Liquid culture: pick two rings of yeast strains activated for 24 hours and inoculate them into YPD liquid medium, the culture conditions are: 24-30°C, 24h, 120rpm;

[0072] (3) Fermented seed liquid culture: absorb the seed liquid cultivated in the YPD liquid medium and add it to a 500ml Erlenmeyer flask equipped with 400ml apple juice to expand the culture to obtain the fermented seed liquid. The culture conditions are: 24-30°C, 24h, 120rpm; the soluble solids content of the apple juice used in this embodiment is 23-25. ;

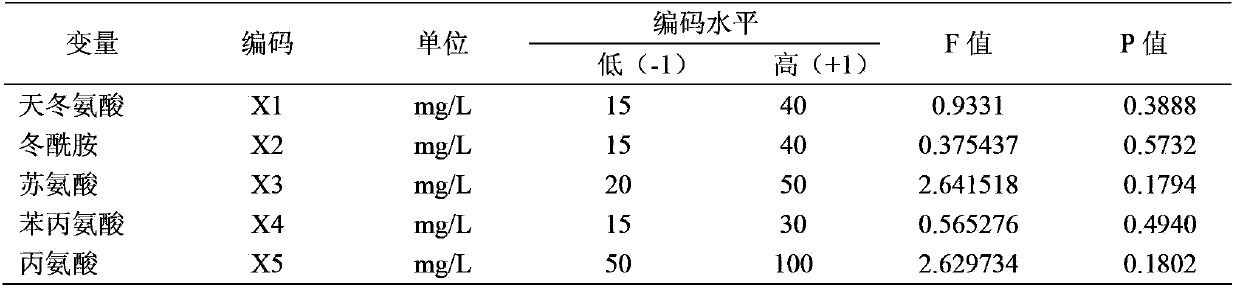

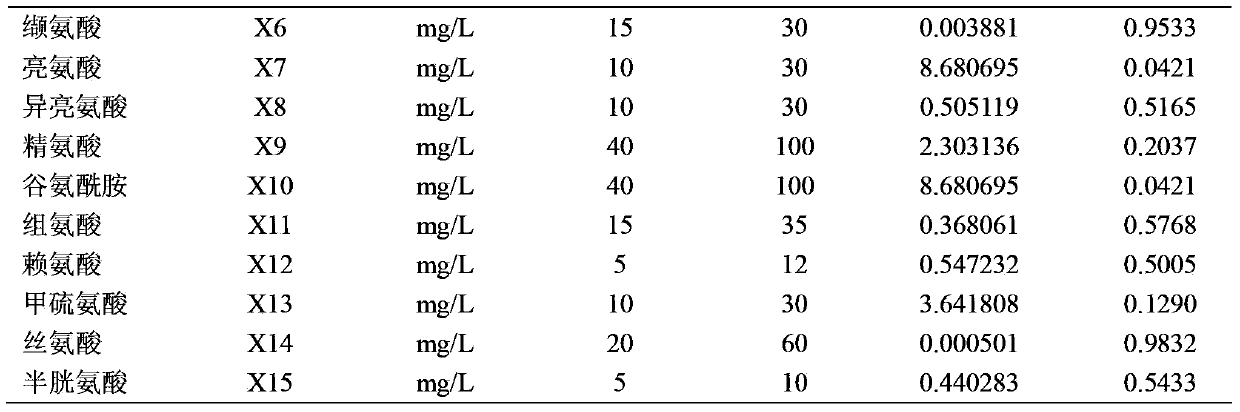

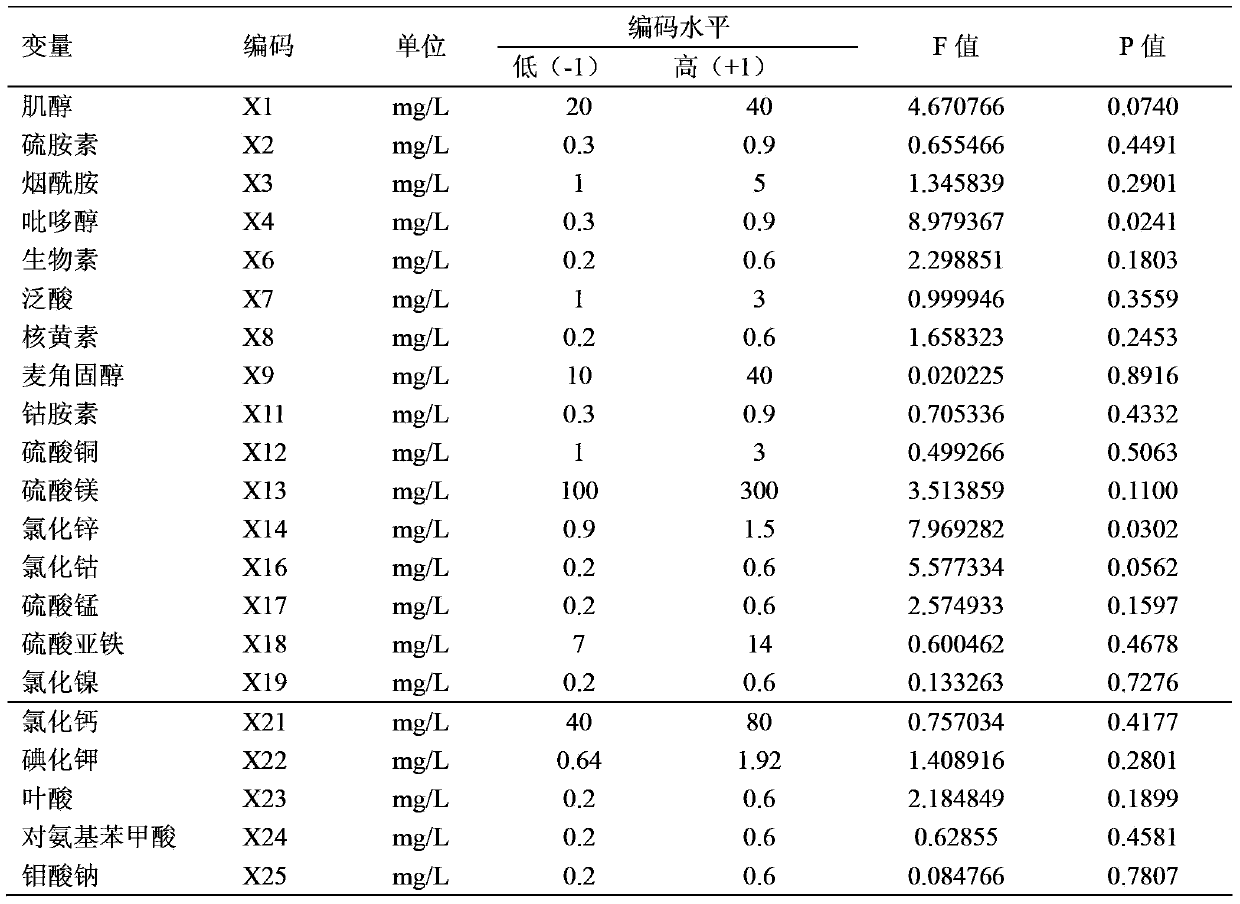

[0073] (4) Fermentation of cider: put 400ml of apple juice in a 500ml conical flask, the added nutrients are leucine 40mg / L, glutamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com