Optical processing system and method

A technology of optical processing and optical system, which is applied in the field of lithography, and can solve problems such as difficulty in realization, difficulty in making microlenses and zone plates, and high requirements for alignment adjustment accuracy of microlenses and zone plates with projection imaging systems , to achieve high energy utilization, high resolution, and improved lithography resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

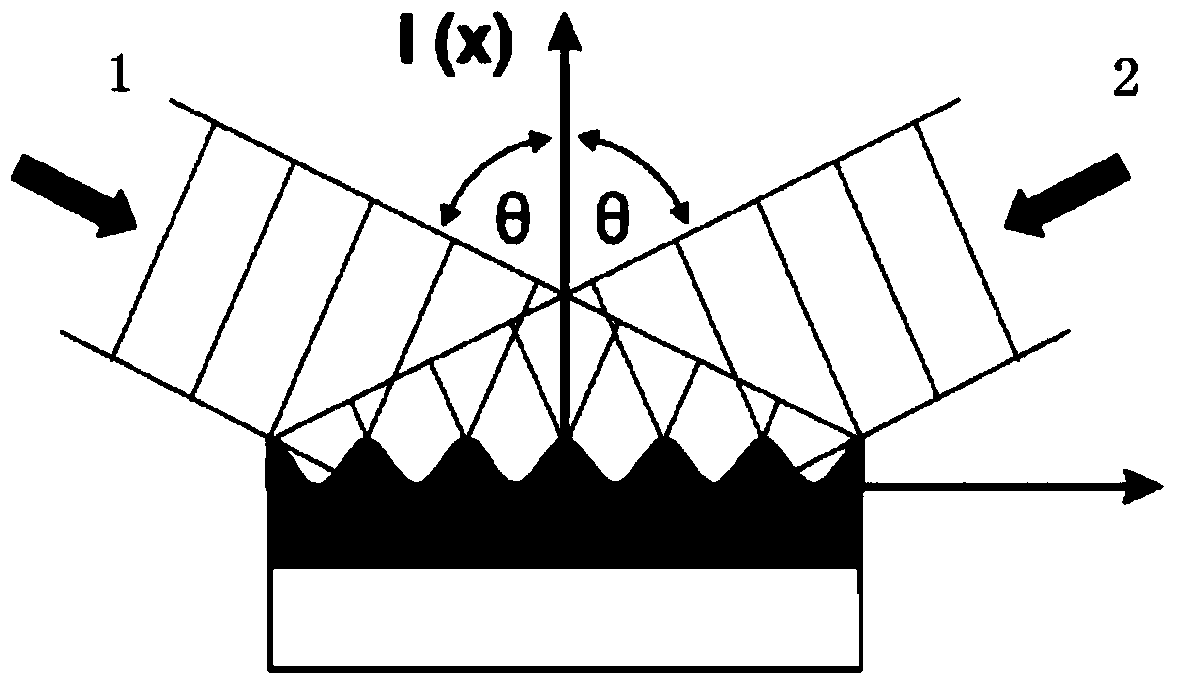

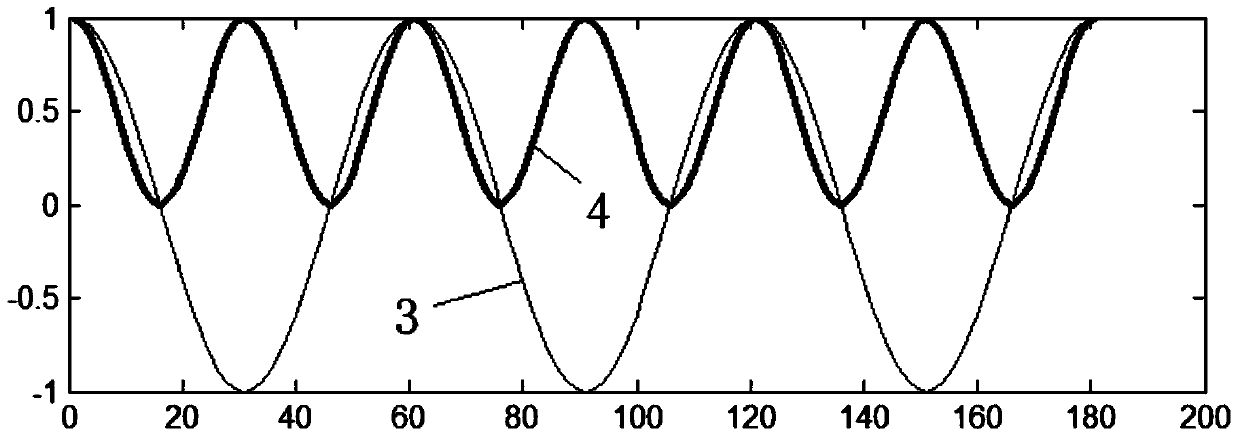

[0058] As mentioned in the background art, in the existing photolithography process, the resolution of the laser direct writing technology is limited by the wavelength of the light wave and the numerical aperture, and there is little room for improvement. Although the interference lithography technology can double the resolution of the laser direct writing technology, but because the etched image can only be an interference pattern, such as vertical stripes or periodic lattices with alternating light and dark, it is difficult to Use graphics with a high degree of freedom.

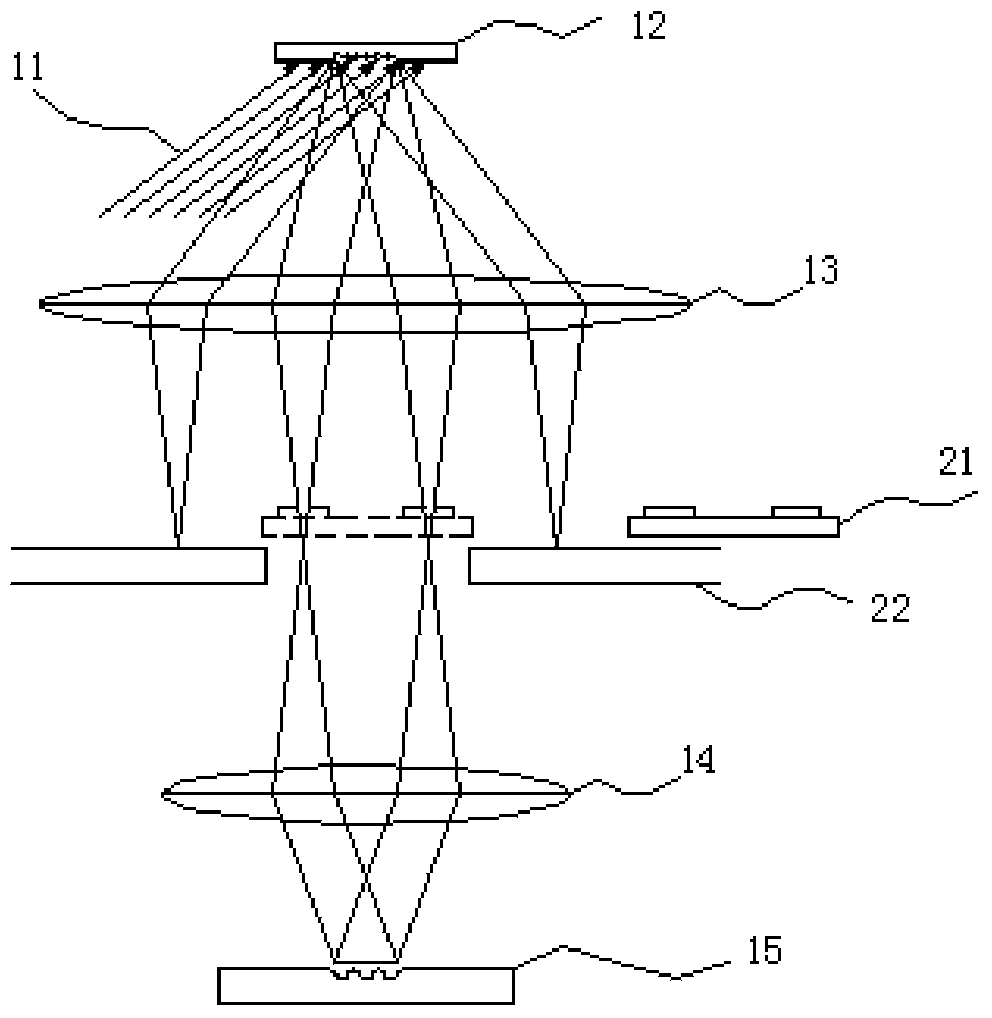

[0059] Therefore, the object of the present invention is to propose an optical processing system and method, which combines the advantages of laser direct writing technology and interference lithography technology, that is, it can pixelate the exposure pattern, thereby exposing any pattern , and can use interference lithography to improve the resolution of the exposure pattern. The optical processing syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com