Method of dicing semiconductor wafer, and dicing tape for processing semiconductor using the same

A cutting method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, stone processing equipment, fine working devices, etc., can solve problems such as complicated procedures, inability to remove support parts, and decreased adhesive force of semiconductor wafers with dicing tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

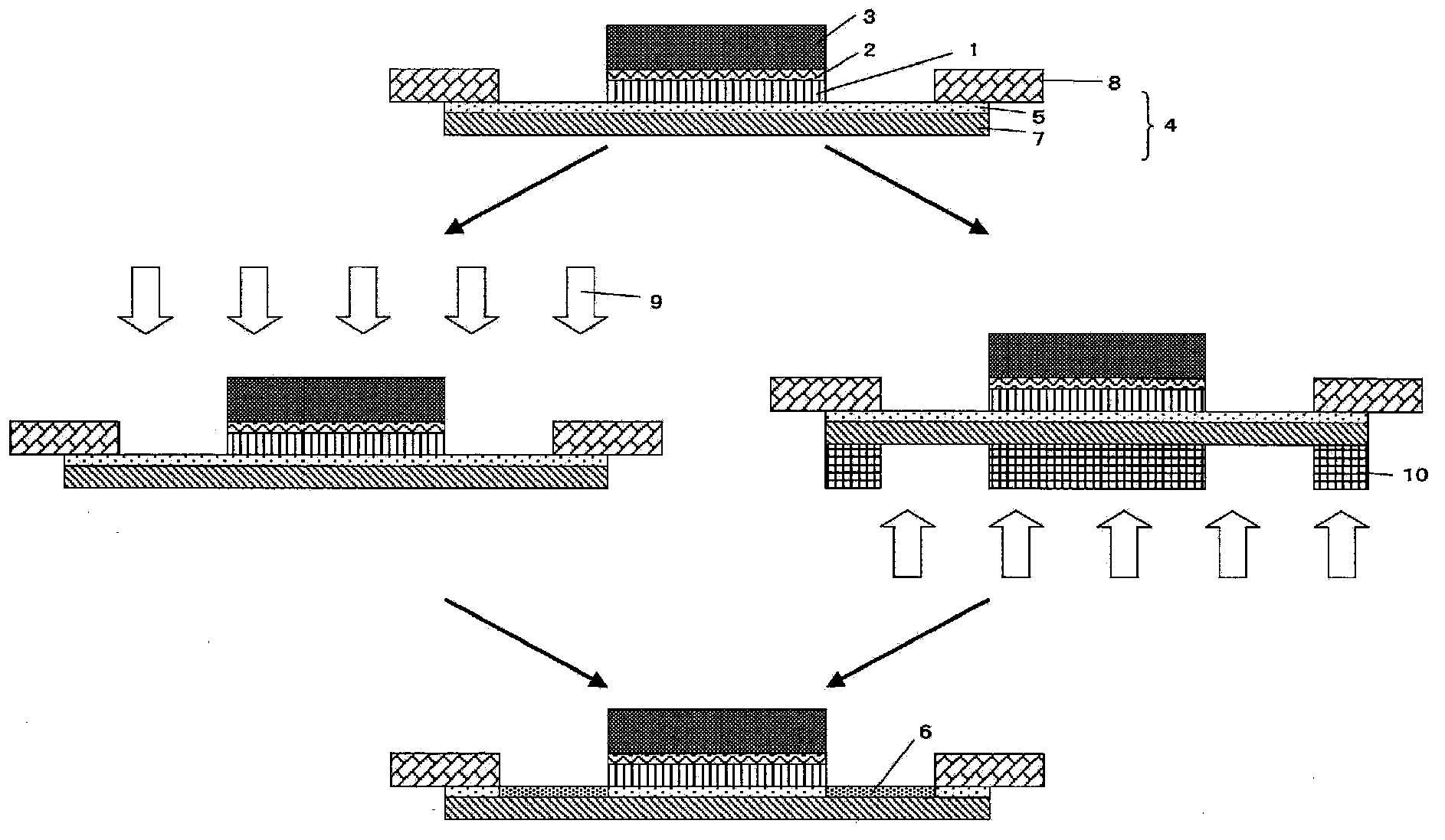

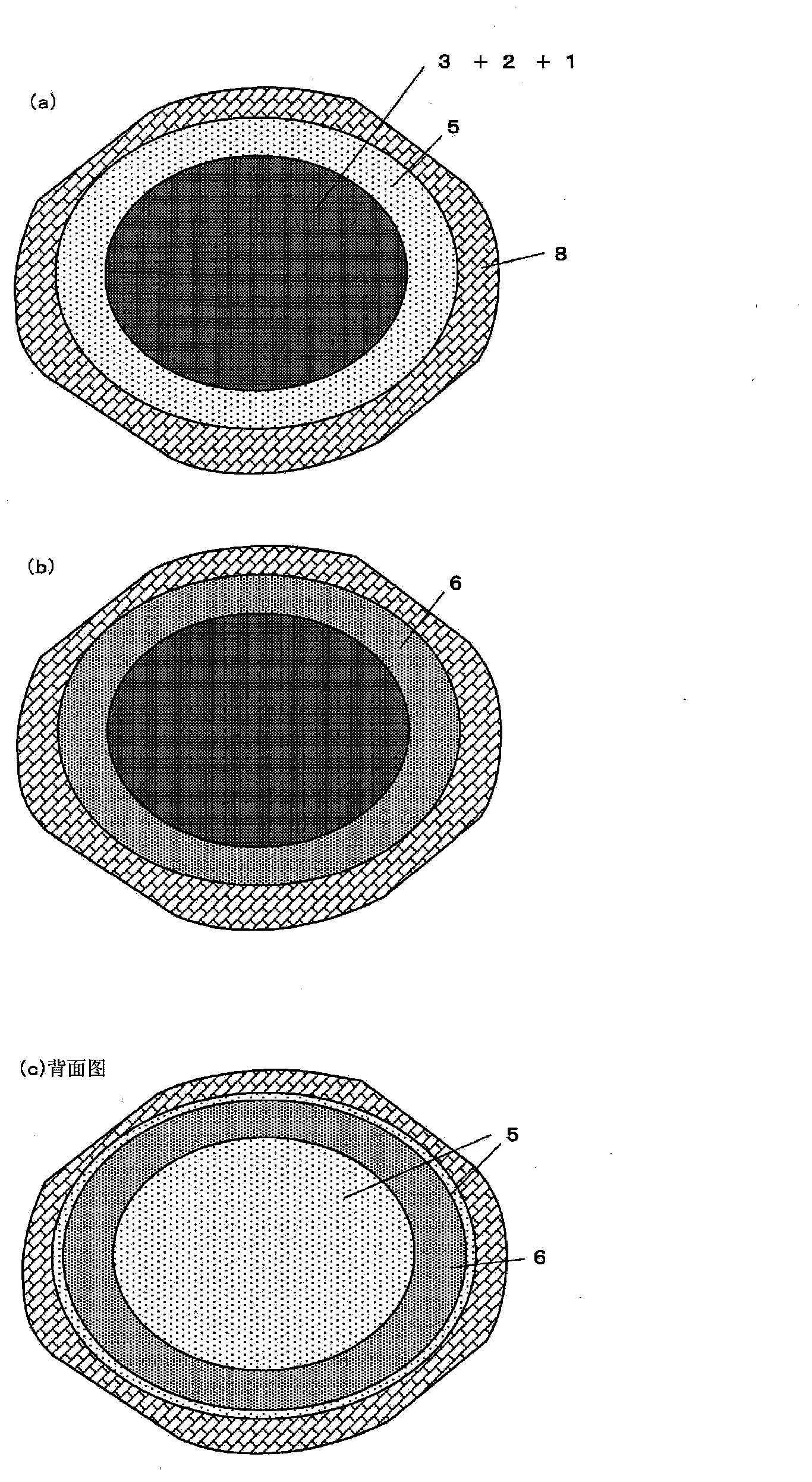

[0054] First, while referring to Figure 1~3 , while describing the first embodiment of the semiconductor wafer processing method (dicing method) of the present invention.

[0055] figure 1 It is a schematic sectional view showing the processing method of the semiconductor wafer 1 according to the first embodiment; figure 2 It is an overall process diagram, which is a cross-sectional view of the semiconductor wafer 1 fixed on the ring frame (dicing frame) 8 .

[0056] The semiconductor wafer 1 of the present invention is a silicon wafer or the like having a pattern surface (not shown) on which a circuit or the like is formed on one side, and a support member 3 is bonded to the circuit surface side via an adhesive (adhesive layer) 2 [ figure 2 (a)] After that, it is supplied to the back grinding (Back Grind) process [ figure 2 (b)].

[0057] After the back grinding (Back Grind) process is finished, on the back of the circuit surface of the semiconductor wafer 1, stick th...

no. 2 Embodiment approach

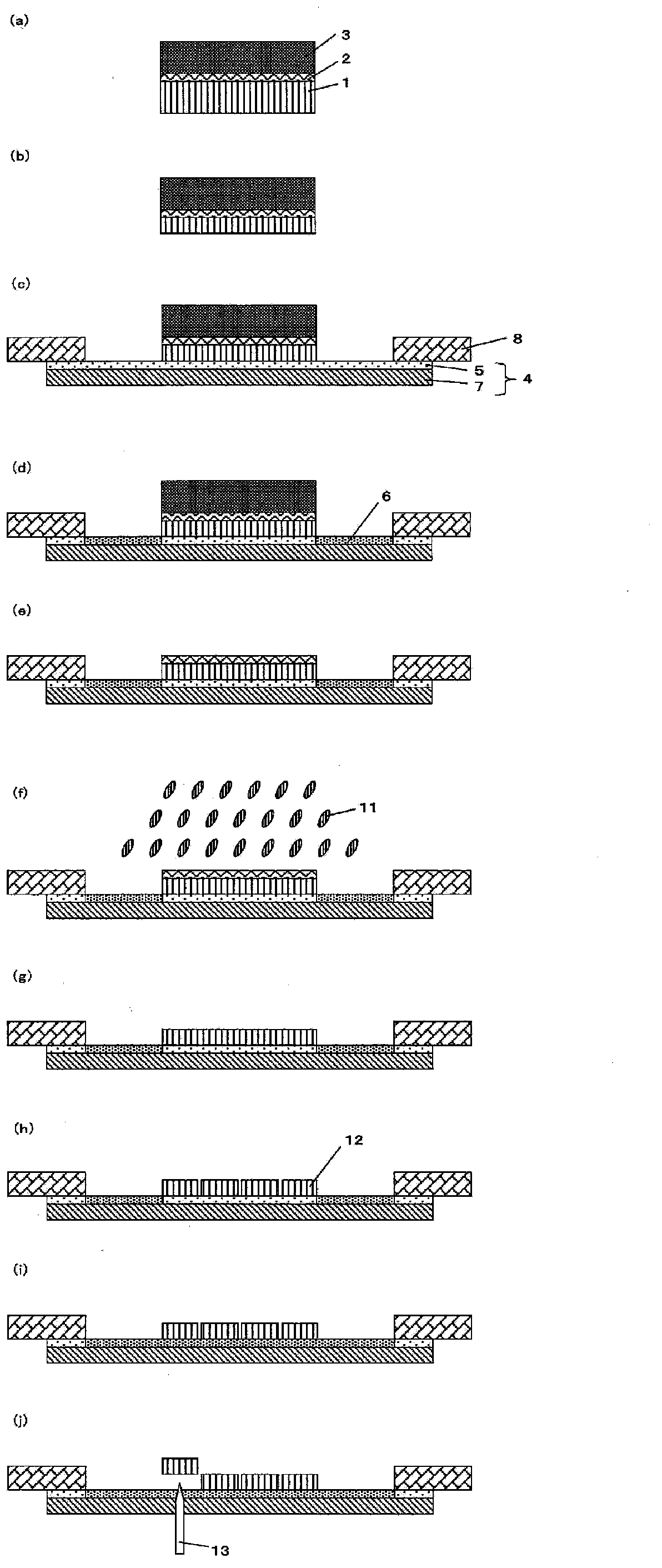

[0065] First, while referring to Figure 4 and Figure 5 A second embodiment of the processing method (dicing method) of the semiconductor wafer 1 of the present invention will be described.

[0066] Figure 4 It is a schematic sectional view of the dicing tape (dicing tape for semiconductor processing) 14 of the second embodiment; Figure 5 It is an overall process view of the second embodiment, and is a schematic cross-sectional view illustrating a method of processing the semiconductor wafer 1 .

[0067] Dicing tape of the present invention (dicing tape for semiconductor processing) 14[ Figure 4 (a)] is a dicing tape for semiconductor processing in which an adhesive layer is formed on at least one surface of a base film (base resin film) 7, the adhesive layer is a radiation-curable adhesive layer, and The adhesive layer in the region where the semiconductor wafer 1 and the ring frame (dicing frame) 8 are not bonded is cured by ultraviolet irradiation in advance.

[00...

Embodiment 1

[0148] For each dicing tape (C1 to C5), the PET film was peeled off from the dicing tape, and the UV-curable adhesive layer of the dicing tape was attached to the semiconductor wafer and the ring frame, and then, under a nitrogen atmosphere, from the semiconductor wafer side An evaluation sample was prepared by irradiating with ultraviolet rays to cure the adhesive layer in the region where the semiconductor wafer was not bonded in advance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com