Organic light-emitting device and preparation method thereof

An electroluminescent device and electroluminescent technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of affecting luminous efficiency, low luminous efficiency of light-emitting devices, and reduced probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

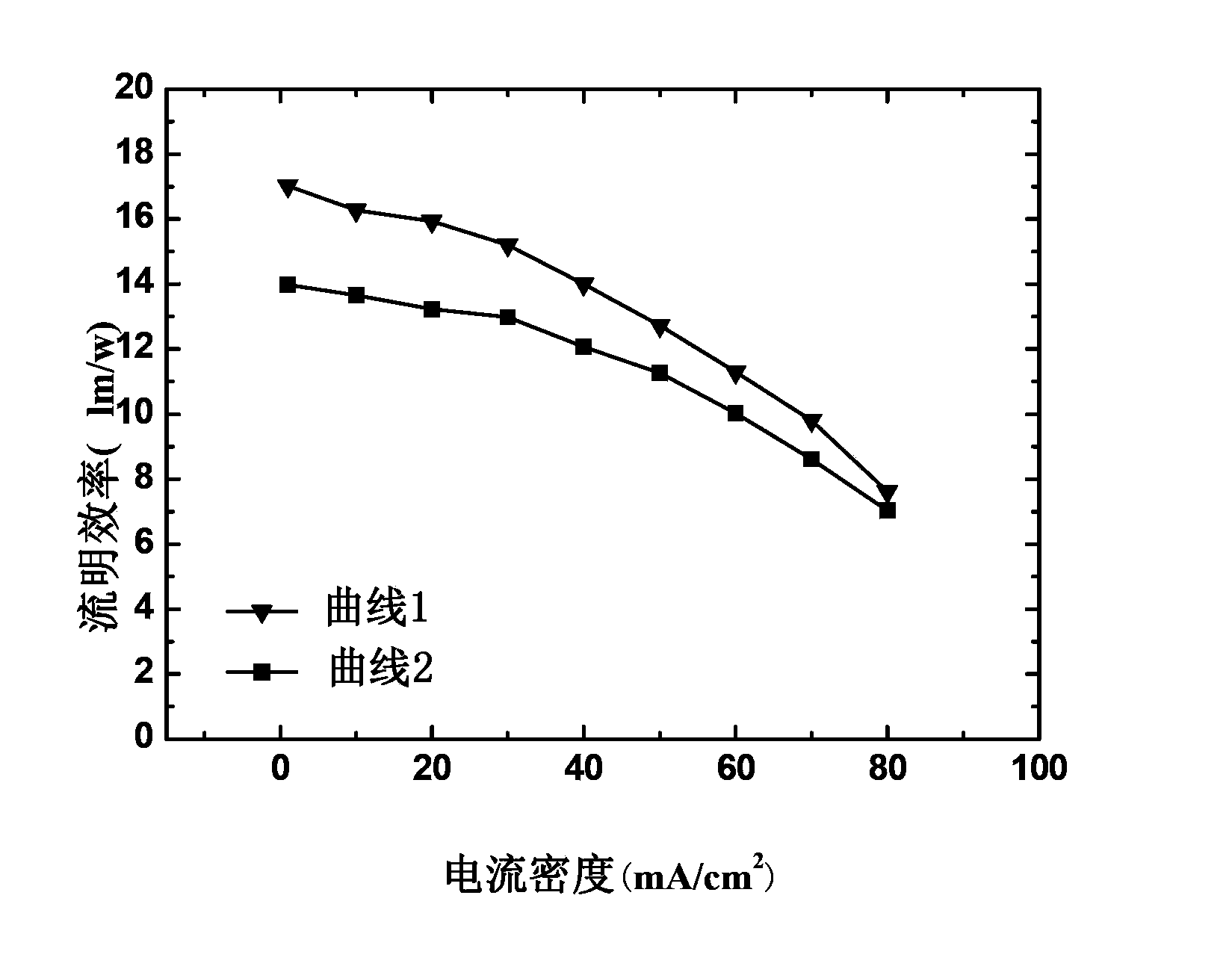

Examples

Embodiment 1

[0074] A method for preparing an organic electroluminescent device, comprising the following steps:

[0075] (1) Wash the glass substrate with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the glass surface; scrape the glass substrate to prepare a scattering layer, and then put it in an oven to dry the water.

[0076] Specifically, in this embodiment, the material of the scattering layer is a mixed material formed by doping carbon aerogel with a polytetrafluoroethylene (PTFE) aqueous solution with a mass fraction of 40%, wherein the doping mass fraction of the carbon aerogel The pore size of the carbon airgel is 120nm; the thickness of the scattering layer is 50μm.

[0077] (2) Prepare an anode conductive film on the scattering layer by magnetron sputtering;

[0078] Specifically, during the magnetron sputtering process, the vacuum degree is 4×10 -3 Pa, the sputtering power is 150W, and the material of the anode conductive film is ...

Embodiment 2

[0086] A method for preparing an organic electroluminescent device, comprising the following steps:

[0087] (1) Wash the glass substrate with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the glass surface; spin-coat the glass substrate to prepare a scattering layer, and then put it in an oven to dry the water.

[0088]Specifically, in this embodiment, the material of the scattering layer is a mixed material formed by doping carbon aerogel with a polytetrafluoroethylene (PTFE) aqueous solution with a mass fraction of 60%, wherein the doping mass fraction of the carbon aerogel The pore size of the carbon airgel is 20nm; the thickness of the scattering layer is 200μm. During the spin coating process, the rotational speed was 500 rpm, and the time was 15 s.

[0089] (2) Prepare an anode conductive film on the scattering layer by magnetron sputtering;

[0090] Specifically, during the magnetron sputtering process, the vacuum degree is...

Embodiment 3

[0096] A method for preparing an organic electroluminescent device, comprising the following steps:

[0097] (1) Wash the glass substrate with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the glass surface; spin-coat the glass substrate to prepare a scattering layer, and then put it in an oven to dry the water.

[0098] Specifically, in this embodiment, the material of the scattering layer is a mixed material formed by doping carbon aerogel with a polytetrafluoroethylene (PTFE) aqueous solution with a mass fraction of 20%, wherein the doping mass fraction of the carbon aerogel The pore size of the carbon airgel is 200nm; the thickness of the scattering layer is 200μm. During the spin coating process, the rotational speed was 3000 rpm and the time was 20 s.

[0099] (2) Prepare an anode conductive film on the scattering layer by magnetron sputtering;

[0100] Specifically, during the magnetron sputtering process, the vacuum degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com