Manufacturing method of quantum dot light-emitting component and quantum dot displaying device

A technology of quantum dot light-emitting and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problems of complex processes, many processes for quantum dot light-emitting components, and difficulty in reducing manufacturing costs, and simplify the manufacturing process. , The effect of improving the dissolution problem and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

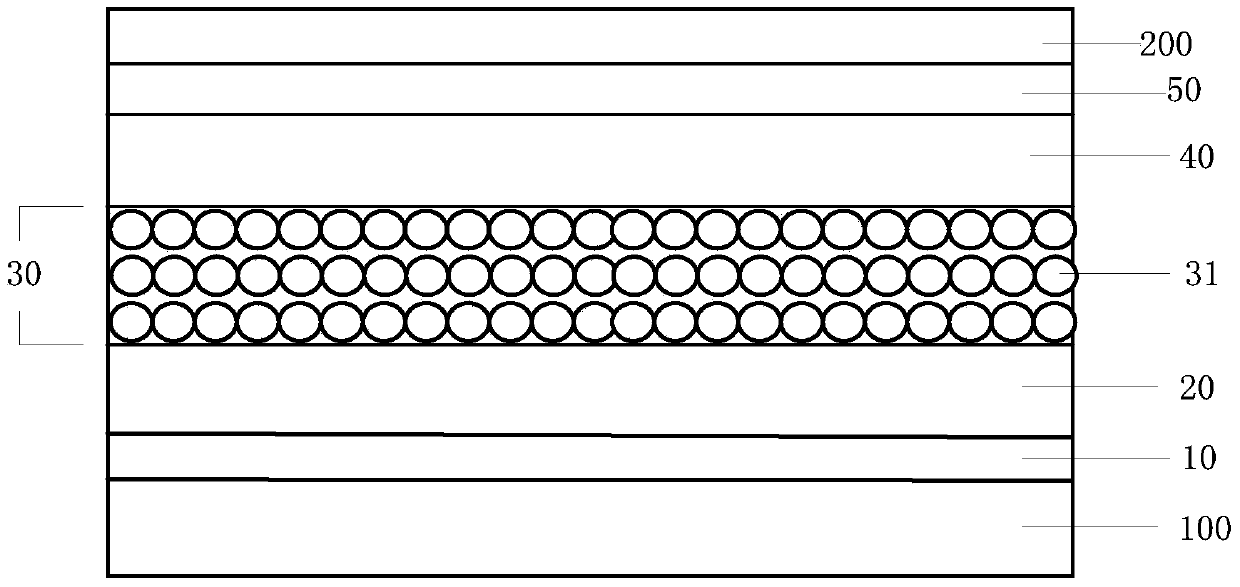

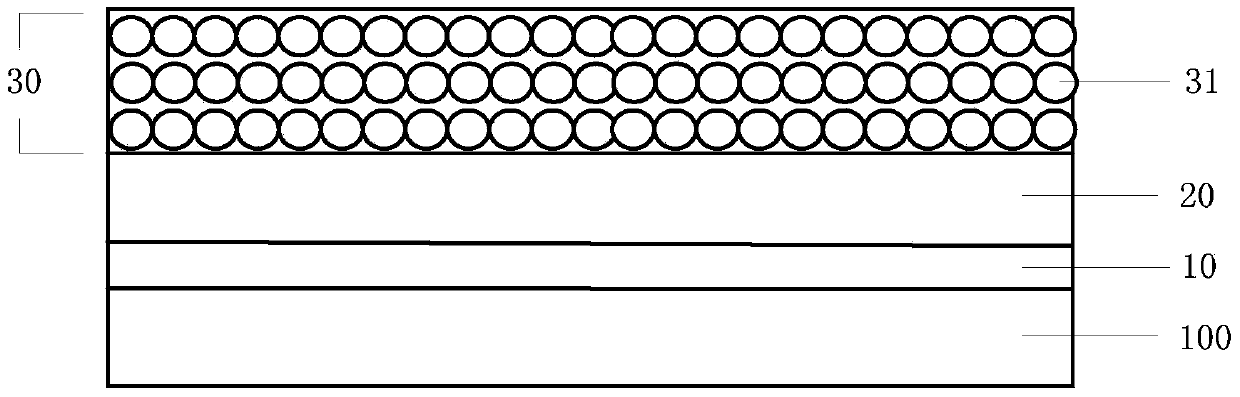

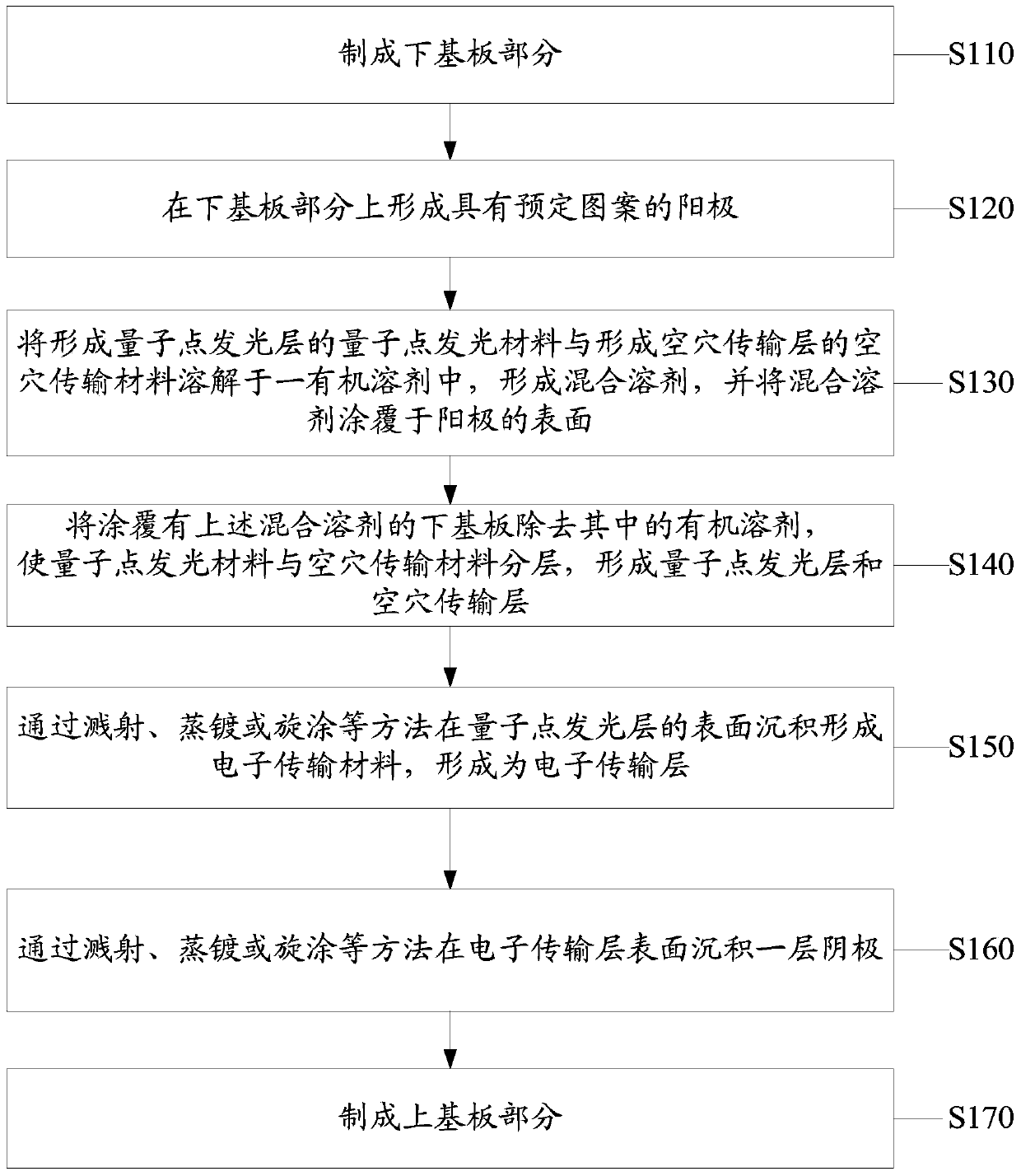

[0055] removing the organic solvent on the prepared substrate coated with the mixed solvent, layering the quantum dot luminescent material and the hole transport material or the quantum dot luminescent material and the electron transport material forming the electron transport layer on the prepared substrate, Forming the quantum dot light emitting layer and the hole transport layer or forming the quantum dot light emitting layer and the electron transport layer.

[0056] Using the above method, the quantum dot light-emitting layer and the hole transport layer (or the electron transport layer) can be formed through a one-step process without further layered manufacturing, thus simplifying the manufacturing process of the quantum dot light-emitting element, The manufacturing cost of the quantum dot light-emitting element can be further reduced.

[0057] In addition, the mixed solvent can be formed on the prepared substrate by common solution coating processes such as spin coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com