Compound mannitol injection and preparation method thereof

A technology of mannitol and injection, which is applied in the field of compound mannitol injection and its preparation, can solve the problems of poor stability and easy crystallization, and achieve the effect of mild process conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Recipe (by weight):

[0035] D-mannitol: 150 parts;

[0036] Anhydrous glucose: 50 parts;

[0037] Sodium chloride: 4.5 parts;

[0038] Propylene glycol: 0.75 part;

[0039] Water for injection: 1000 parts.

[0040] making process:

[0041] (1) Concentrated blend:

[0042] At a temperature of about 50°C, firstly dissolve the accurately weighed raw material mannitol and propylene glycol with water for injection (the amount of water for injection is enough to dissolve mannitol and propylene glycol), and then dissolve the dissolved solution with 0.22 μm The ultrafilter performs ultrafiltration to obtain the ultrafiltered mannitol solution.

[0043] Heat about 1 / 3 of the volume (relative to the total amount of water for injection) of water for injection to a temperature of about 50°C, pour it into the concentrated preparation tank, start stirring, and add the ultrafiltered mannitol solution, accurately weighed Water glucose and sodium chloride are added to the above-...

Embodiment 2

[0065] Recipe (by weight):

[0066] D-mannitol: 170 parts;

[0067] Anhydrous glucose: 80 parts;

[0068] Sodium chloride: 6.0 parts;

[0069] Propylene glycol: 0.5 parts;

[0070]Water for injection: 1000 parts.

[0071] making process:

[0072] (1) Concentrated blend:

[0073] At a temperature of about 50°C, first dissolve the accurately weighed raw material mannitol and propylene glycol with water for injection, and then perform ultrafiltration on the dissolved solution with a 0.22 μm ultrafiltration machine to obtain an ultrafiltered mannitol solution .

[0074] Heat about 1 / 4 volume (relative to the total amount of water for injection) of water for injection to a temperature of about 50°C, pour it into the concentrated preparation tank, start stirring, and add the ultrafiltered mannitol solution, accurately weighed Water glucose and sodium chloride are added to the above-mentioned concentrated preparation tank, stirred to fully dissolve, and 0.02% activated carbon ...

Embodiment 3

[0084] Recipe (by weight):

[0085] D-mannitol: 120 parts;

[0086] Anhydrous glucose: 40 parts;

[0087] Sodium chloride: 4 parts;

[0088] Propylene glycol: 0.5 part;

[0089] Water for injection: 1000 parts.

[0090] The preparation process is the same as in Example 1.

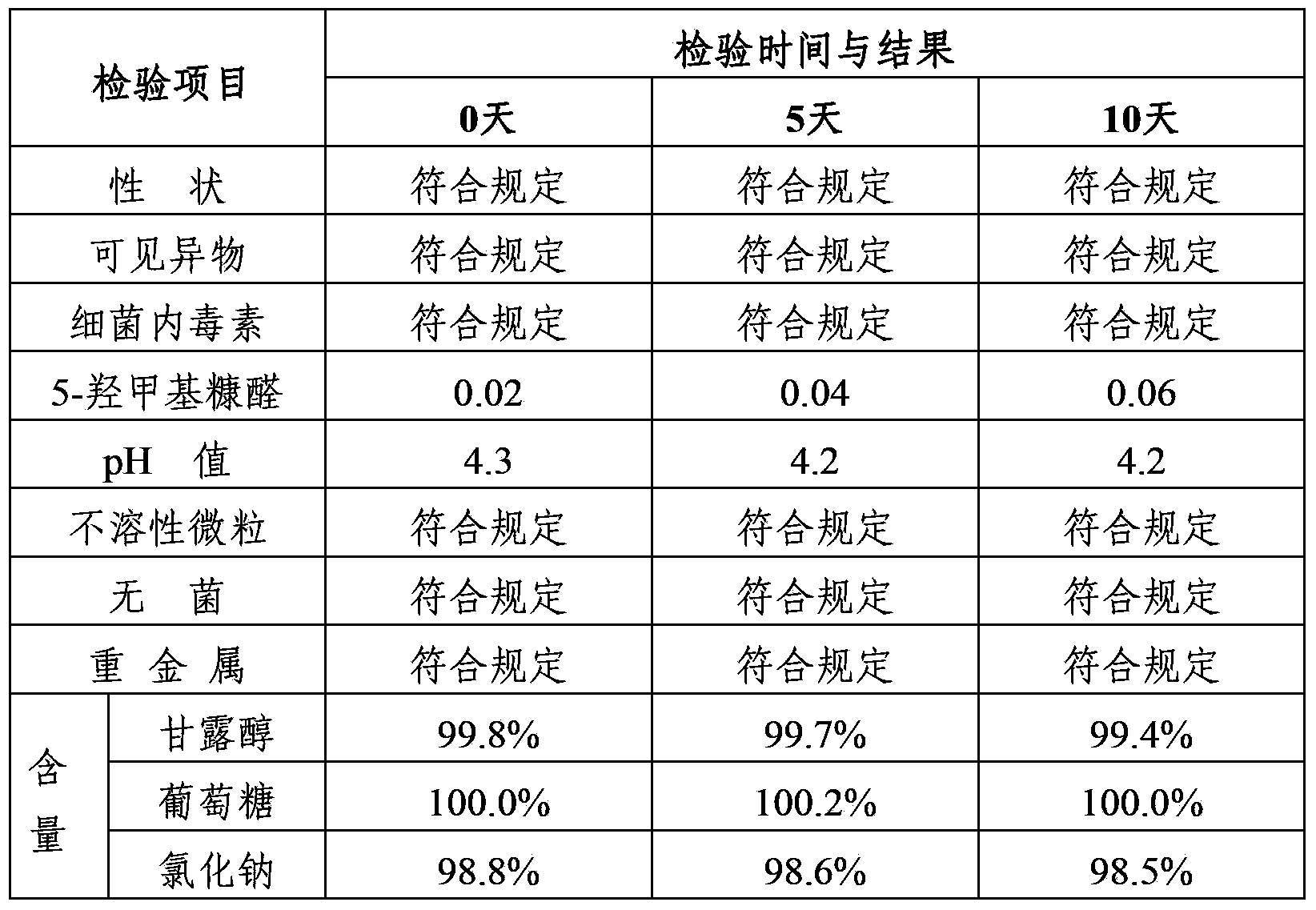

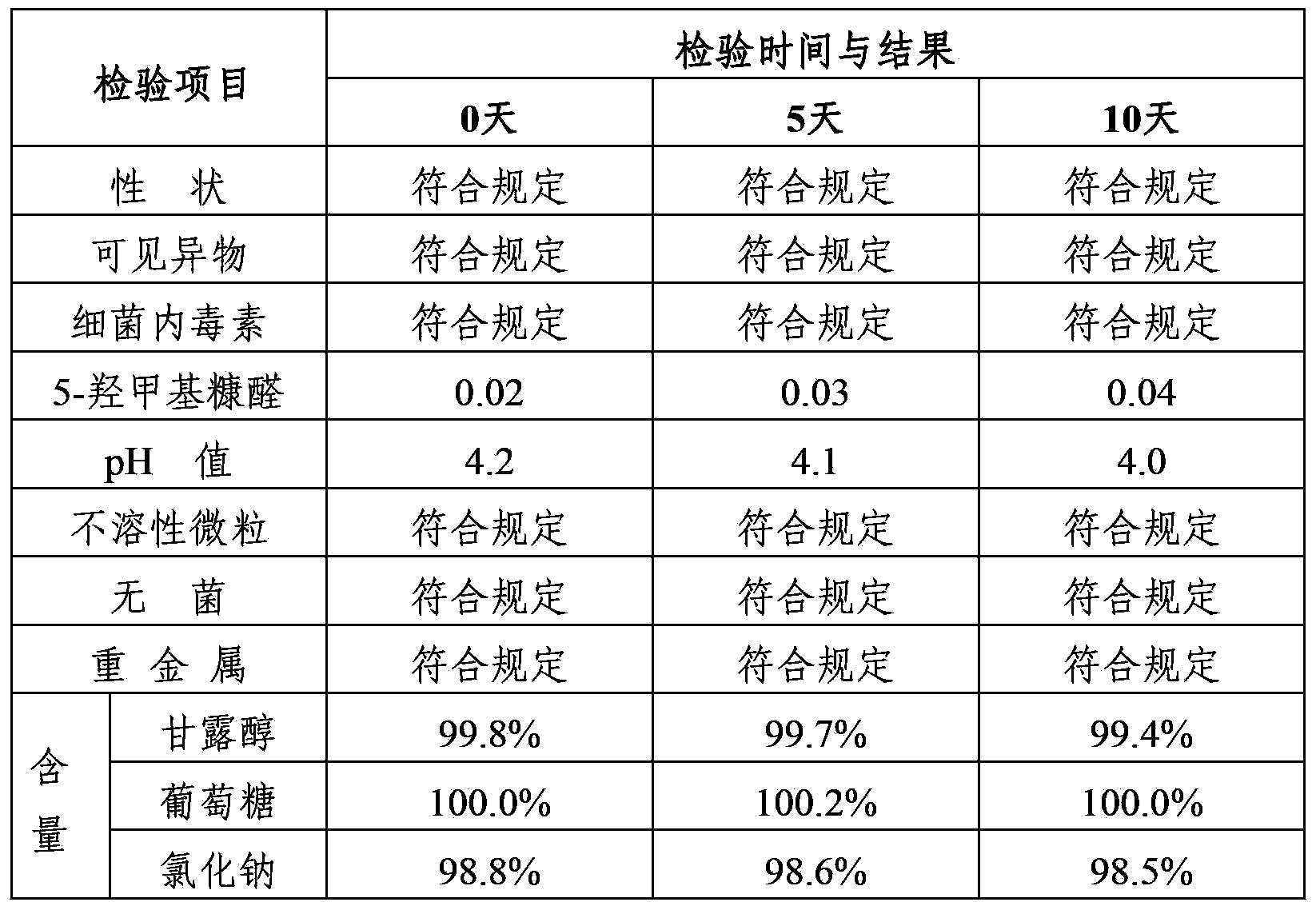

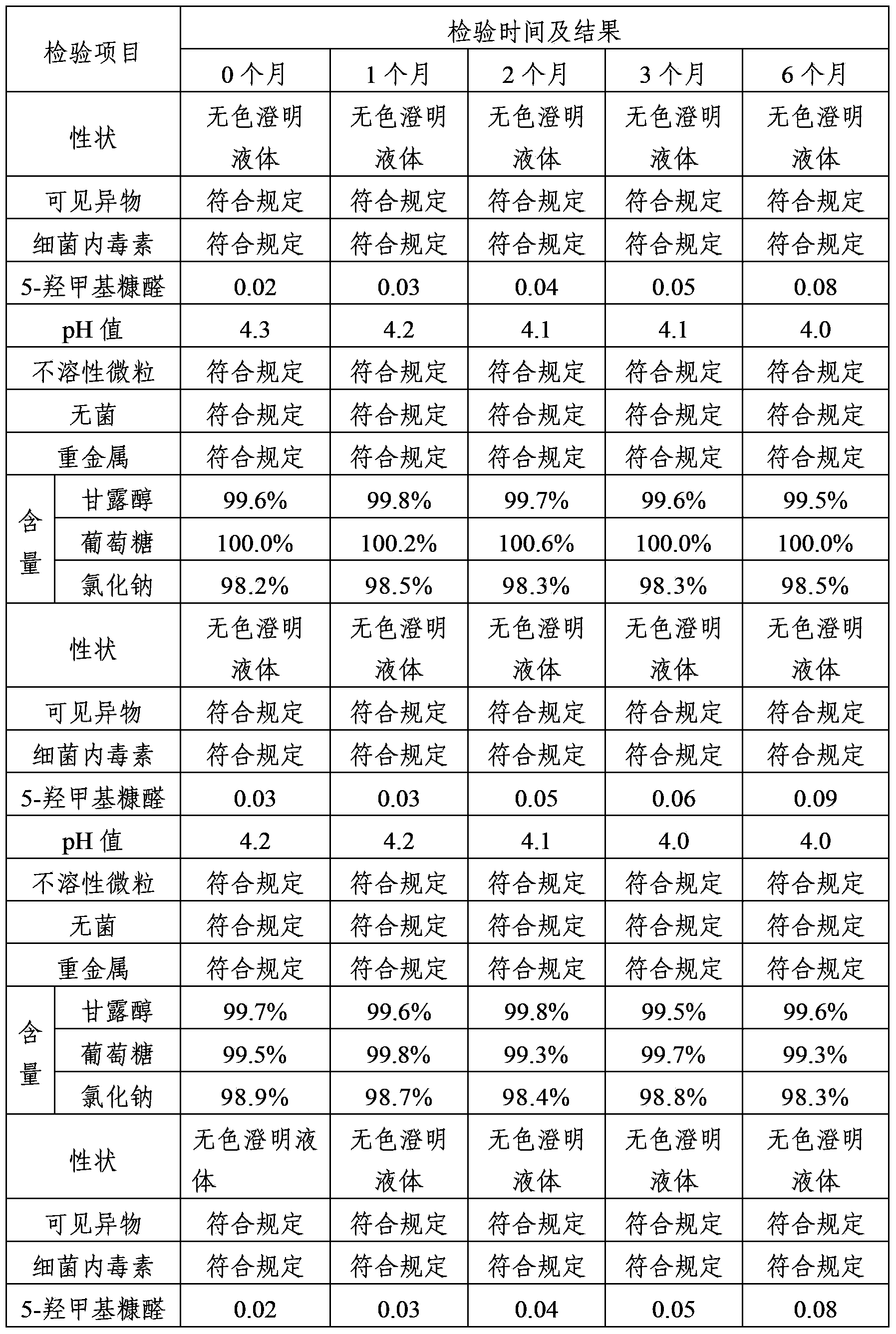

[0091] Through the data analysis of influencing factor test, accelerated test and long-term test, the mannitol content in the above-mentioned injections is all between 95.0%-105.0%; the glucose content is all between 90.0%-110.0%; the sodium chloride content is all between 95.0% %-105.0%, it can be seen that various detection indicators such as foreign matter are within the qualified range of the "Chinese Pharmacopoeia".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com