Preparation method for easily-cleaned hydrophobic membrane used on surface of automotive body

A technology of automobile body and hydrophobic film layer, which is applied in the field of preparation of easy-to-clean hydrophobic film layer, which can solve the problems of easy damage and insufficient bonding force, and achieve the effects of reducing damage, improving bonding force, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Preparation of hydrophobic agent

[0021] Add 3 parts of heptadecafluoroalkyltrimethoxysilane, 1 part of hydrochloric acid (37% by mass) and 2 parts of deionized water into 94 parts of ethanol, and stir at 80°C for 30 minutes to obtain solution A;

[0022] Add 2 parts of 3-aminopropyltriethoxysilane, 10 parts of vinyltriethoxysilane and 1 part of acetic acid into 87 parts of ethanol, stir at room temperature for 50 minutes, and obtain solution B.

[0023] Step 2: Preparation of hydrophobic film layer

[0024] First, clean the surface of the varnish layer with ethanol to remove dust and pollutants on the surface, and keep the surface dry. Then mix solution A and solution B evenly according to the ratio of 1:1, then wipe the mixed solution on the surface of the body paint, and finally dry it at room temperature for 4 hours.

Embodiment 2

[0026] Step 1: Preparation of hydrophobic agent

[0027] Add 5 parts of octadecyltrimethyloxysilane, 2 parts of nitric acid (10% by mass) and 3 parts of deionized water into 90 parts of ethyl acetate, and stir at 50°C for 70 minutes to obtain solution A;

[0028] Add 1 part of γ-(2,3 glycidoxy)propyltrimethoxysilane, 5 parts of γ-chloropropyltriethoxysilane and 1 part of hydrochloric acid (mass fraction 37%) to 93 parts of ethyl acetate , and stirred at room temperature for 20 min to obtain solution B.

[0029] Step 2: Preparation of hydrophobic film layer

[0030] First, clean the surface of the varnish layer with ethanol to remove dust and pollutants on the surface, and keep the surface dry. Then mix solution A2 and solution B2 evenly according to the ratio of 2:1, then wipe the mixed solution on the surface of the body paint, and finally dry it at room temperature for 24 hours.

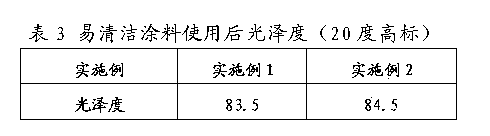

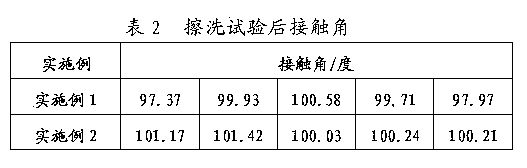

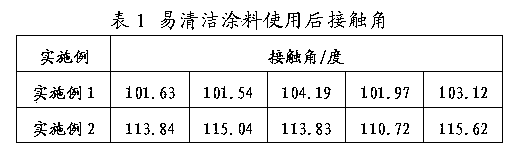

[0031] Initial contact angle test method: test environment (23±2) ℃, RH (50±5)%, the test me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com