Processing method of crosswise laminated plate

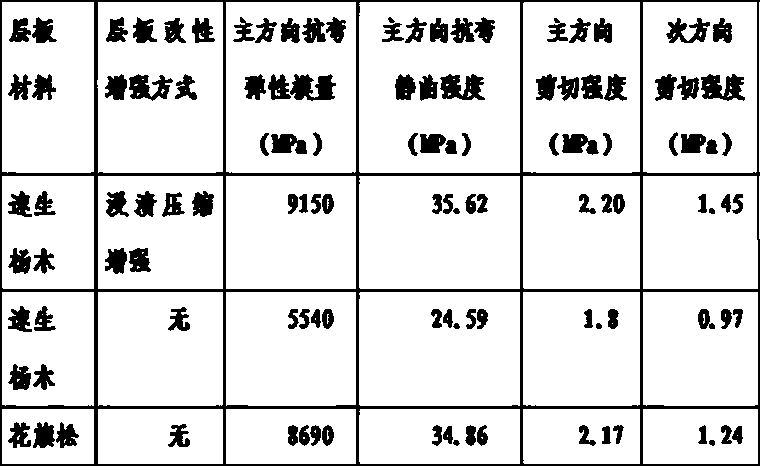

A board processing method and cross-lamination technology, which is applied in the direction of wood processing appliances, manufacturing tools, and the joining of wooden veneers, can solve the problems of high cost, poor mechanical properties, and large variability, so as to expand the scope of use, High-quality development and excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Process step 1: laminate preparation

[0023] Fast-growing poplar boards with a moisture content of 12% and a thickness of 40 mm were selected to remove defective parts of the sawn timber, including knots, worm holes and warped parts, and planed on four sides of the sawn timber.

[0024] Process Step 2: Composite Modifier Configuration

[0025] Mix the low-molecular phenolic resin adhesive, the powdered nano-silver ion antibacterial agent and the phosphorus-nitrogen flame retardant with a pH value of 11 in a weight ratio of 100:1:15 and mix evenly.

[0026] Process Step 3: Modification and enhancement of surface laminates

[0027] Put the surface laminate into a closed pressure tank, vacuumize the closed pressure tank, the vacuum degree is 0.09MPa, keep it for 4 hours, the composite modifier is sucked into the sealed pressure tank under the action of pressure difference; The tank is pressurized, the pressure is 1.0MPa, and it is kept for 4 hours. The composite modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com