Cross-laminated sheet processing method

A board processing method and cross-lamination technology, applied in chemical instruments and methods, layered products, wood-layered products, etc., can solve the problems of high cost, poor mechanical properties, large variability, etc., to expand the scope of use, The effect of excellent performance and high-quality development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

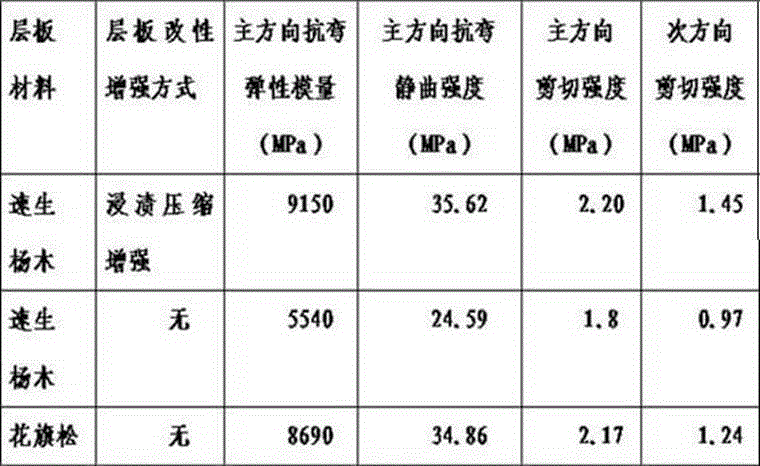

Examples

Embodiment

[0018] Process step 1: laminate preparation

[0019] Fast-growing poplar boards with a moisture content of 12% and a thickness of 40 mm were selected to remove defective parts of the sawn timber, including knots, worm holes and warped parts, and planed on four sides of the sawn timber.

[0020] Process Step 2: Composite Modifier Configuration

[0021] Mix the low-molecular phenolic resin adhesive, the powdered nano-silver ion antibacterial agent and the phosphorus-nitrogen flame retardant with a pH value of 11 in a weight ratio of 100:1:15 and mix evenly.

[0022] Process Step 3: Modification and enhancement of surface laminates

[0023] Put the surface laminate into a closed pressure tank, vacuumize the closed pressure tank, the vacuum degree is 0.09MPa, keep it for 4 hours, the composite modifier is sucked into the sealed pressure tank under the action of pressure difference; The tank is pressurized, the pressure is 1.0MPa, and it is kept for 4 hours. The composite modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com