Method for preventing catkin fouling

A catkin and flocculent sludge technology, applied in the field of circulating water treatment, can solve problems such as the threat of safe production of the thermal system, the decrease of the working efficiency of the heat exchanger, and the large filtration accuracy, and achieve considerable economic and safety environmental benefits, avoiding work Reduced efficiency, simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

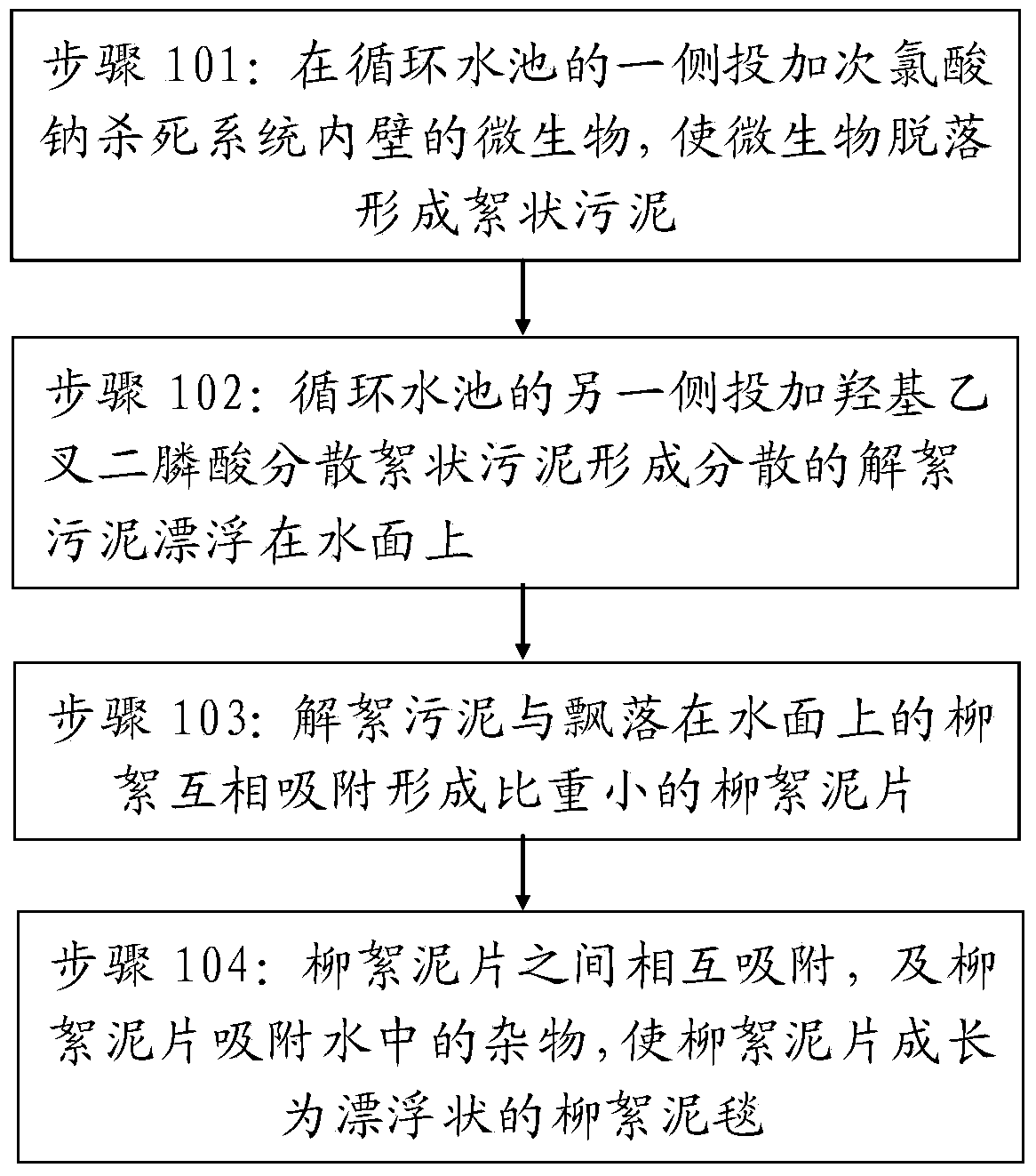

[0018] see figure 1 A method for preventing catkin fouling provided by an embodiment of the present invention is applied to an open circulating water system, comprising the following steps:

[0019] Step 101: adding sodium hypochlorite to one side of the circulating pool of the system to kill the microorganisms on the inner wall of the system, so that the microorganisms fall off to form flocculent sludge;

[0020] Step 102: Adding hydroxyethylidene diphosphonic acid on the other side of the circulating water tank to disperse the flocculent sludge to form dispersed deflocculation sludge floating on the water surface;

[0021] Step 103: the flocculent sludge and the catkins floating on the water surface are adsorbed to each other to form catkin mud flakes with a small specific gravity;

[0022] Step 104: The catkin mud pieces are adsorbed to each other, and the catkin mud pieces absorb impurities in the water, so that the catkin mud pieces grow into a floating catkin mud blanke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com