Sequencing batch bio-membrane reactor method capable of achieving partial nitrification

A sequencing batch biofilm and short-range nitrification technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of long sludge age, limited short-range nitrification technology, unsuitable for urban sewage treatment, etc., and achieve a small sludge output , Reduce sludge production, stabilize and efficiently treat sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

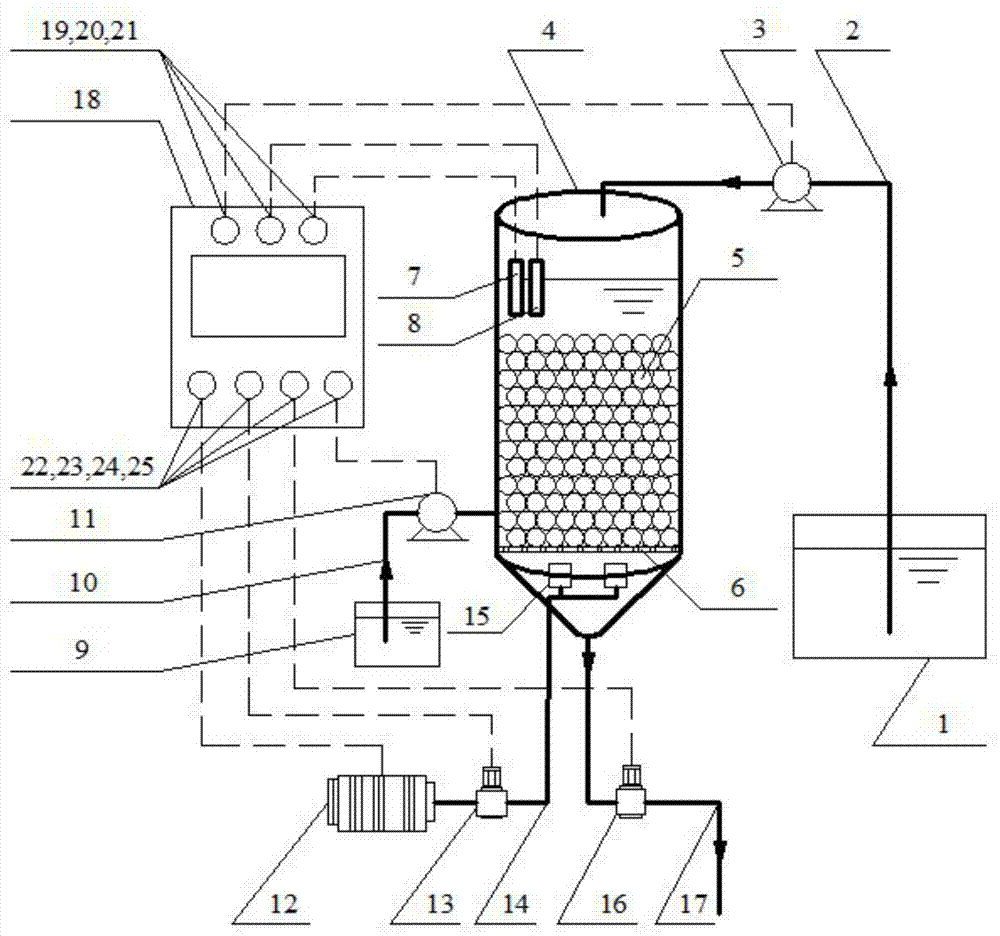

[0030] The sequence batch biofilm reactor 4 is connected to the water inlet pipe 2 and the lye pipe 10; the water inlet pump 3 is arranged on the water inlet pipe 2; the drain valve 16 is arranged on the drain pipe 17; the aeration valve 13 is arranged on the aeration pipe 14; the lye pipe 10 is provided with an alkali adding pump 11; the raw water tank 1 is connected to the sequence batch type biofilm reactor 4 through the water inlet pipe 2; the lye tank 9 is connected to the sequence batch type biofilm reactor 4 through the lye pipe 10; the air compressor 12 Connect to sequence batch type biofilm reactor 4 by aeration pipe 14; In sequence batch type biofilm reactor 4, pH sensor 7, dissolved oxygen (DO) sensor 8, aeration sand head 15, perforated support tray 6, Filler (ceramsite) 5; pH sensor 7, DO sensor 8 are connected to programmable process controller 18; programmable process controller 18 is provided with water inlet relay 19, DO sensing interface 20, pH sensing interfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com