Optimized formula and preparation process for W2000 liquid stock of mushroom breathing bag cultivated species

A breathing bag, cultivar technology, applied in horticulture, botanical equipment and methods, fertilizer mixtures, etc., can solve the problems of slow inoculation speed, insufficient loose agglomeration, uneven bacteria removal, etc., to improve production efficiency and avoid agglomeration Problem, effect that inoculation is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

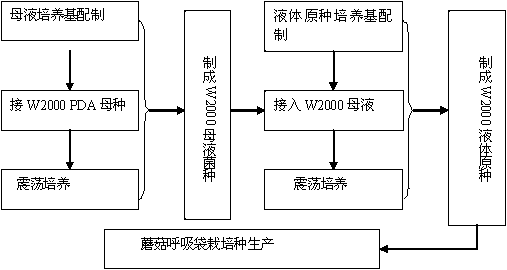

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of W2000 mother liquor strains

[0036] a. Accurately weigh 150g potatoes, 75g bran, 15g brown sugar, 3g peptone, KH 2 PO 4 3g, MgSO 4 ·7H 2 O 1.13g;

[0037] b. Add 0.45 L of distilled water to the potatoes and bran, heat to boiling, filter with four layers of gauze after 20 minutes, discard the potato residue and bran residue, and obtain the potato and bran mixed filtrate for later use.

[0038] c, add 3g KH to the mixed filtrate 2 PO4 and 1.13g MgSO 4 ·7H 2 O, stir evenly, pour into a 2L graduated cylinder, make up the mixed solution to 1.5L with distilled water, which is the mother liquor culture medium;

[0039] d. Pour 100mL mother liquor culture medium into a 250mL conical flask with a 100mL graduated cylinder, and plug the bottle with a silica gel stopper;

[0040] e. 0.1Mpa, 121°C high-pressure steam sterilization for 20min;

[0041] f. After the mother liquid medium is cooled, put it in the ultra-clean workbench and irradiate it with u...

Embodiment 2

[0061] 1. Preparation of W2000 mother liquor

[0062] a. Accurately weigh 200g potatoes, 100g bran, 20g brown sugar, 4g peptone, KH 2 PO 4 4g, MgSO 4 ·7H 2 O 1.5g;

[0063] b. Add 0.6L of distilled water to the potatoes and bran, heat to boiling, filter with four layers of gauze for 20 minutes, discard the potato residue and bran residue, and obtain the potato and bran mixed filtrate for later use.

[0064] c, add 4g KH to the mixed filtrate 2 PO 4 and 1.5g MgSO 4 ·7H 2 O, stir evenly, pour into a 2L graduated cylinder, make up the mixed solution to 2L with distilled water, which is the mother liquor culture medium;

[0065] d. Pour 100mL mother liquor culture medium into a 250mL conical flask with a 100mL graduated cylinder, and plug the bottle with a silica gel stopper;

[0066] e. 0.1Mpa, 121°C high-pressure steam sterilization for 20min;

[0067] f. After the mother liquid medium is cooled, put it in the ultra-clean workbench and irradiate it with ultraviolet li...

Embodiment 3

[0083] 1) Preparation of W2000 mother liquor:

[0084] a. Preparation of mother liquor culture medium;

[0085] Accurately weigh 100g potato, 50g bran, 10g brown sugar, 2g peptone, KH 2 PO 4 2g, MgSO 4 ·7H 2 O 0.75g; Add 0.3L distilled water to potatoes and bran and heat to boiling, filter with four layers of gauze for 20min, discard potato residue and bran residue, and obtain potato and bran mixed filtrate for subsequent use. Add 2.0 g KH to the combined filtrate 2 PO 4 and 0.75g MgSO 4 ·7H 2 O, stir evenly, pour into a 1L graduated cylinder, make up the mixed solution to 1L with distilled water, which is the mother culture medium.

[0086] Measure 100mL of liquid seed medium in a 100mL graduated cylinder and pour it into a 250mL triangular flask with a silicone stopper; 0.1Mpa, 121°C high-pressure steam sterilization for 20min; after the mother liquor medium is cooled, place it in an ultra-clean workbench and irradiate it with ultraviolet light for 30min.

[0087] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com