Method for extracting high-purity inulin from jerusalem artichoke by ultrasonic-complex enzyme method

A kind of compound enzymatic method and the technology of pure inulin, which is applied in the field of Jerusalem artichoke processing and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0155] A method for extracting high-purity inulin from Jerusalem artichoke by ultrasonic synergistic composite enzyme method, comprising the following steps:

[0156] Step 1: Extraction process

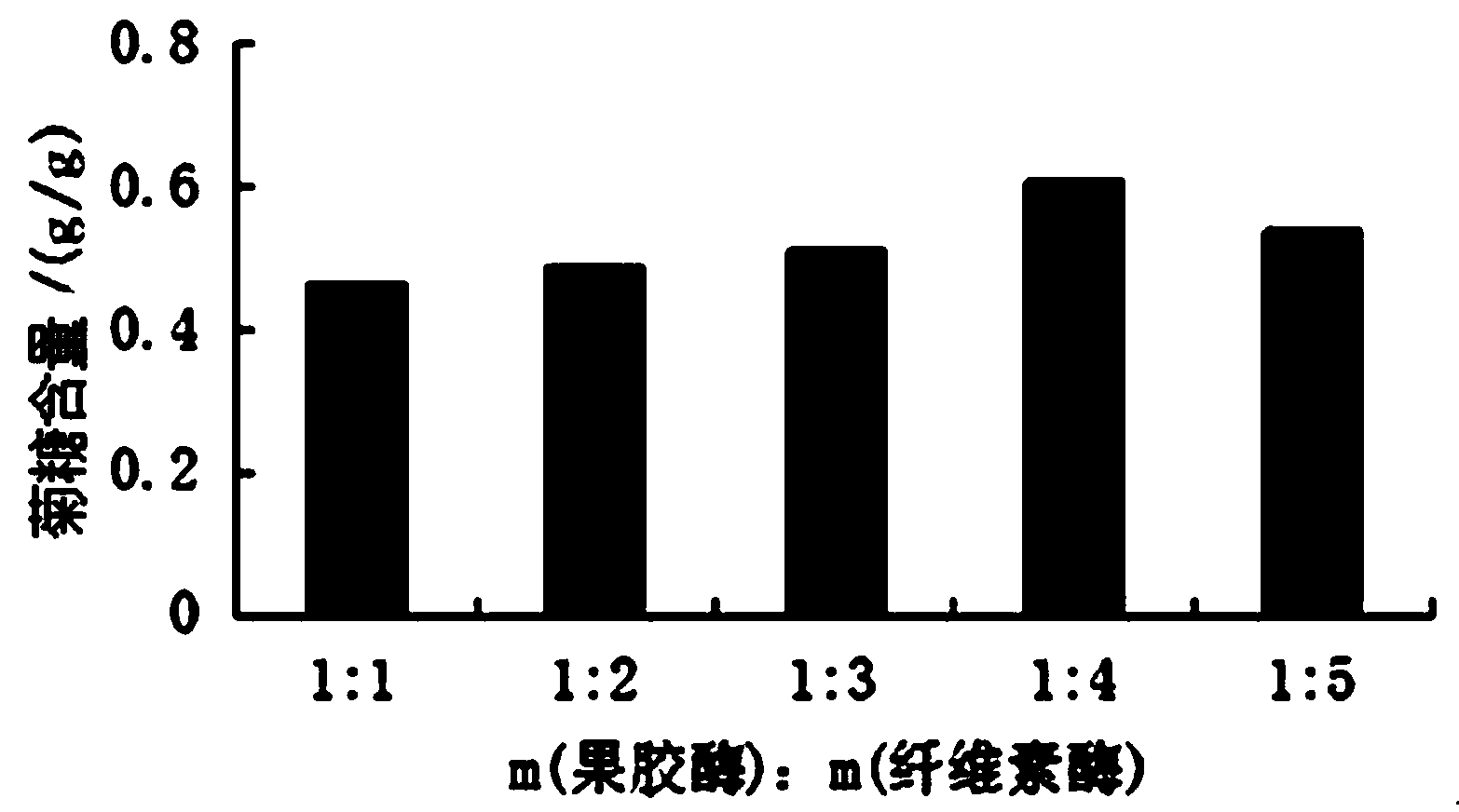

[0157] (1) Cut the Jerusalem artichoke tubers into slices, dry them at a temperature of 55°C, crush them, pass through a 80-mesh sieve, and obtain the Jerusalem artichoke powder; The pH value is 5.7; (3) Then add the compound enzyme and stir evenly. The amount of enzyme added per gram of Jerusalem artichoke powder is 140 μg. The compound enzyme is a mixture of cellulase and pectinase at a weight ratio of 1:4 (4) Put the mixture obtained in step (3) into an ultrasonic cleaning machine, the ultrasonic power is 250W, the time is 28 minutes, and the temperature is kept at 53°C; (5) Inactivate the enzyme and filter to obtain the crude inulin extract;

[0158] Step 2: Purification process

[0159] (1) Put the pretreated resins D280 and D151 into the chromatography column according to the ...

Embodiment 3

[0161] A method for extracting high-purity inulin from Jerusalem artichoke by ultrasonic synergistic composite enzyme method, comprising the following steps:

[0162] Step 1: Extraction process

[0163] (1) Cut the Jerusalem artichoke tubers into slices, dry them at a temperature of 51°C, crush them, pass through a 80-mesh sieve, and obtain the Jerusalem artichoke powder; The pH value is 5.5; (3) Then add the compound enzyme and stir evenly. The amount of enzyme added per gram of Jerusalem artichoke powder is 120 μg. The compound enzyme is a mixture of cellulase and pectinase at a weight ratio of 1:4 (4) Put the mixture obtained in step (3) into an ultrasonic cleaning machine, the ultrasonic power is 240W, the time is 25 minutes, and the temperature is kept at 51°C; (5) Inactivate the enzyme and filter to obtain a crude inulin extract;

[0164] Step 2: Purification process

[0165] (1) Put the pretreated resins D280 and D151 into the chromatography column according to the ma...

Embodiment 4

[0167] A method for extracting high-purity inulin from Jerusalem artichoke by ultrasonic synergistic composite enzyme method, comprising the following steps:

[0168] Step 1: Extraction process

[0169] (1) Cut the Jerusalem artichoke tubers into slices, dry them at a temperature of 48°C, crush them, pass through a 80-mesh sieve, and obtain the Jerusalem artichoke powder; The pH value is 5.4; (3) Then add the compound enzyme and stir evenly. The amount of enzyme added per gram of Jerusalem artichoke powder is 130 μg. The compound enzyme is a mixture of cellulase and pectinase at a weight ratio of 1:4 ; (4) Put the mixture obtained in step (3) into ultrasonic wave, the ultrasonic power is 220W, the time is 27 minutes, and the temperature is kept at 50°C; (5) Inactivate the enzyme and filter to obtain the crude inulin extract;

[0170] Step 2: Purification process

[0171](1) Put the pretreated resins D280 and D151 into the chromatography column according to the mass ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com