Tire transition layer and preparation method thereof

A transition layer and tire technology, applied in the field of rubber synthesis, can solve the problems of hidden tire quality, low tire performance, short life, etc., achieve good physical performance transition, reduce production costs, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

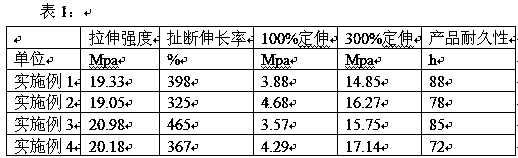

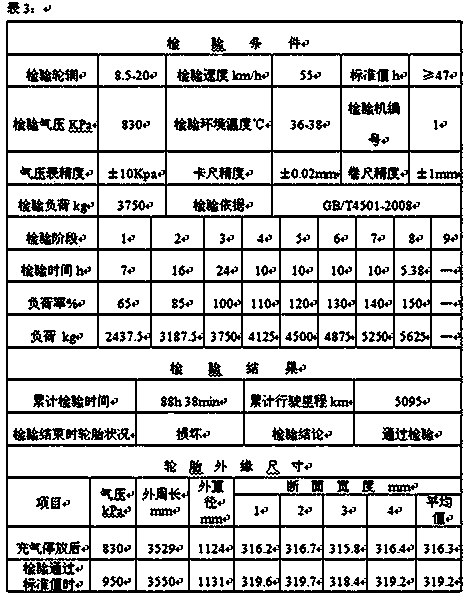

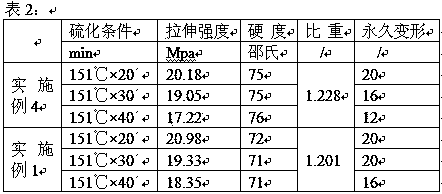

Examples

Embodiment 1

[0025] A tire transition layer containing butadiene rubber, in parts by weight, comprises 100 parts of rubber, wherein rubber comprises 85 parts of natural rubber and 15 parts of high cis-butadiene rubber BR9000, 60 parts of carbon black N326, 8 parts of oxidation Zinc, 1.2 parts meta-methyl resin, 2 parts calcium metasilicate, 1 part N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine, 1.5 parts 2,2,4-trimethyl Base-1,2-dihydroquinoline polymer, 4.5 parts of insoluble sulfur OT20, 1.5 parts of vulcanization accelerator N-tert-butyl-2-benzothiazole sulfenamide, 3.8 parts of methylene donor 1,3, 5-triazine hexamethoxymethylmelamine, 0.2 parts of anti-scorch agent N-cyclohexylthiophthalimide, wherein the m-formaldehyde resin is the reaction of resorcinol and styrene with formaldehyde product.

[0026] A method for preparing tire transition layer rubber, wherein the added raw materials are added according to the above weight parts, and the production process steps are as follows:...

Embodiment 2

[0035]A tire transition layer containing butadiene rubber, in parts by weight, comprises 100 parts of rubber, wherein rubber includes 70 parts of natural rubber and 30 parts of high cis-butadiene rubber BR9000, 65 parts of carbon black N326, 6 parts of oxidation Zinc, 1 part of metamethyl resin, 1 part of calcium metasilicate, 1.2 parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine, 1 part of 2,2,4-trimethyl Base-1,2-dihydroquinoline polymer, 4 parts of insoluble sulfur OT20, 1.5 parts of vulcanization accelerator N-tert-butyl-2-benzothiazole sulfenamide, 3 parts of methylene donor 1,3, 5-triazine hexamethoxymethylmelamine, 0.2 parts of anti-scorch agent N-cyclohexylthiophthalimide, wherein the m-formaldehyde resin is the reaction of resorcinol and styrene with formaldehyde product.

[0036] A method for preparing tire transition layer rubber, wherein the added raw materials are added according to the above weight parts, and the production process steps are as follows...

Embodiment 3

[0045] A tire transition layer containing butadiene rubber, in parts by weight, comprises 100 parts of rubber, wherein rubber comprises 90 parts of natural rubber and 10 parts of high cis-butadiene rubber BR9000, 57 parts of carbon black N326, 10 parts of oxidation Zinc, 7 parts of metamethyl resin, 4 parts of calcium metasilicate, 2 parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine, 2 parts of 2,2,4-trimethyl Base-1,2-dihydroquinoline polymer, 5 parts of insoluble sulfur OT20, 1.5 parts of vulcanization accelerator N-tert-butyl-2-benzothiazole sulfenamide, 5 parts of methylene donor 1,3, 5-triazine hexamethoxymethylmelamine, 0.2 parts of anti-scorch agent N-cyclohexylthiophthalimide, wherein the m-formaldehyde resin is the reaction of resorcinol and styrene with formaldehyde product.

[0046] A method for preparing tire transition layer rubber, wherein the added raw materials are added according to the above weight parts, and the production process steps are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com