Hydrophobic heat-insulating coating for transparent glass and preparation method thereof

A heat-insulating coating and transparent glass technology, applied in the direction of reflection/signal coating, polyurea/polyurethane coating, coating, etc., can solve the problems of light pollution, difficult to clean, easy to stick to water, etc., and achieve low heat transfer coefficient, automatic Good cleaning durability and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

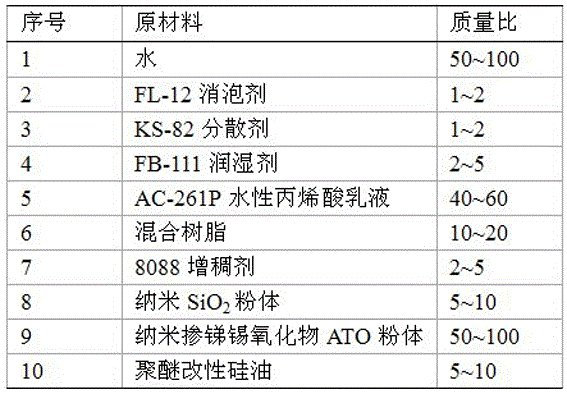

Method used

Image

Examples

Embodiment 1

[0020] In 50 parts of water, add 1 part of FL-12 defoamer, 2 parts of KS-82 dispersant and 3 parts of FB-111 wetting agent, then add 50 parts of nano antimony-doped tin oxide ATO powder, and then in the horizontal Sand mill ball mill for 5-6 hours to prepare a non-settling nano-powder dispersion.

[0021] Add 40 parts of AC-261P water-based acrylic emulsion and 10 parts of water-based polyurethane to 10 parts of water, pour into the nano powder dispersion, stir at low speed for 1 hour, then add 2 parts of 8088 thickener, stir at low speed for 0.5 hours, as a comparison sample .

[0022] The measured contact angle is 63°, the visible light transmittance is 88%, the infrared transmittance is 45%, and the ultraviolet transmittance is 71%.

Embodiment 2

[0024] In 50 parts of water, add 1 part of FL-12 defoamer, 2 parts of KS-82 dispersant and 3 parts of FB-111 wetting agent, then add 70 parts of nano-antimony-doped tin oxide ATO powder and 5 parts of nano-SiO 2 The powder is then ball milled in a horizontal sand mill for 5-6 hours to prepare a non-settling nano-powder dispersion.

[0025] Add 40 parts of AC-261P water-based acrylic emulsion and 10 parts of water-based polyurethane to 10 parts of water, pour into the nano-powder dispersion, stir at low speed for 1 hour, then add 3 parts of 8088 thickener, and stir at low speed for 0.5 hours.

[0026] The measured contact angle is 92°, the visible light transmittance is 72%, the infrared transmittance is 41%, and the ultraviolet transmittance is 54%.

Embodiment 3

[0028] In 50 parts of water, add 2 parts of FL-12 defoamer, 3 parts of KS-82 dispersant and 5 parts of FB-111 wetting agent, then add 80 parts of nano antimony-doped tin oxide ATO powder and 7 parts of nano SiO 2 The powder is then ball milled in a horizontal sand mill for 5-6 hours to prepare a non-settling nano-powder dispersion.

[0029] Add 60 parts of AC-261P water-based acrylic emulsion and 10 parts of water-based polyurethane to 10 parts of water, pour into the nano powder dispersion, stir at low speed for 1 hour, then add 2 parts of 8088 thickener, and stir at low speed for 0.5 hours.

[0030] The measured contact angle is 110°, the visible light transmittance is 65%, the infrared transmittance is 42%, and the ultraviolet transmittance is 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com