Water-based wallpaper polystyrene foam and preparation method thereof as well as wallpaper

A technology of styrofoam and wallpaper, applied in paper, papermaking, special paper, etc., can solve the problems of poor color rendering ability, loss of color paste, poor adaptability of substrates, etc., to improve adhesion and scrub resistance, The effect of avoiding loss and waste and improving product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

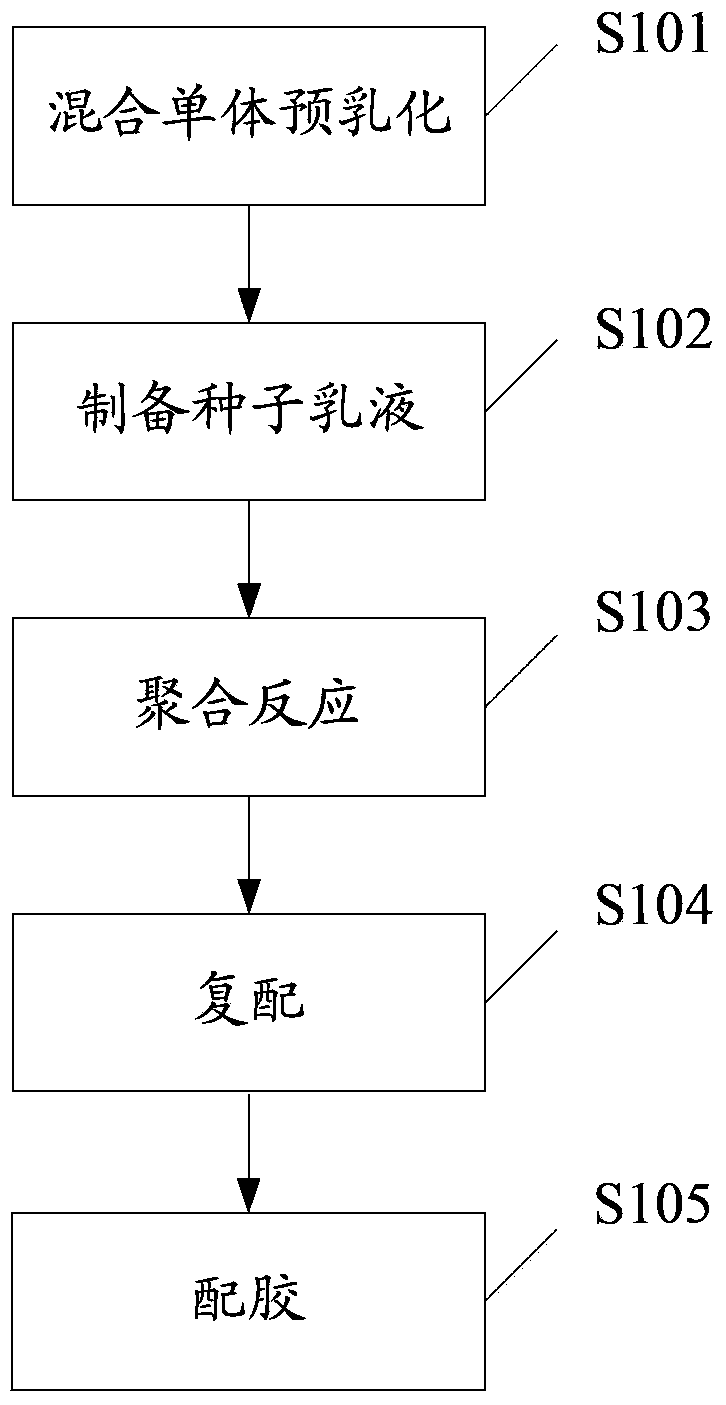

Method used

Image

Examples

Embodiment 1

[0133] 1. Formula: Take 100 parts of component A main emulsion resin and 51.1 parts of component B foam rubber, of which,

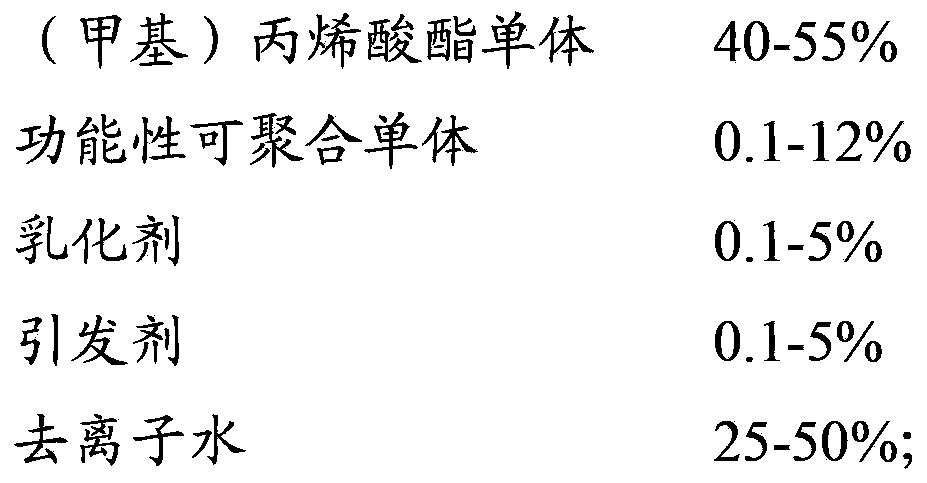

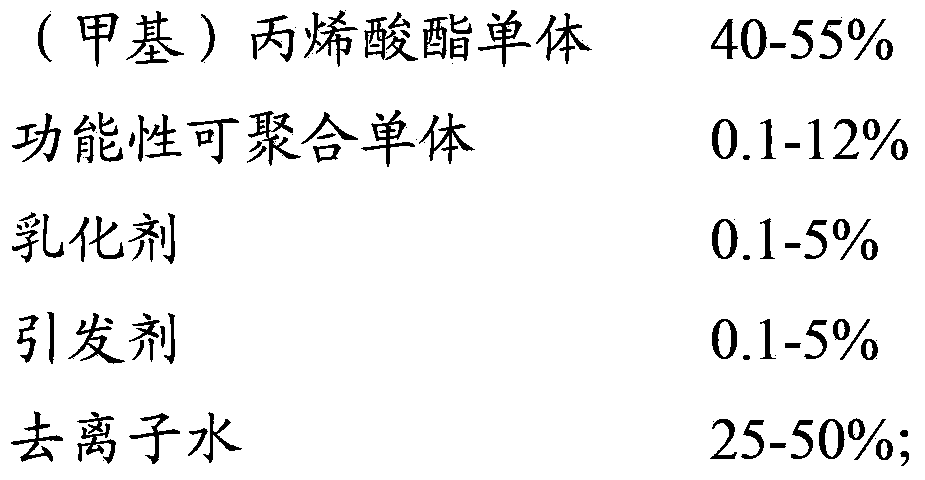

[0134] (1) Component A (main emulsion resin): styrene 8%, butyl acrylate 25%, isooctyl acrylate 15%, methyl methacrylate 8%, 2-hydroxyethyl methacrylate 1%, Acrylic acid 1%, diacetone acrylamide 1%, acrylamide 0.5%, emulsifier (from 0.5% hydroxypropane methacrylate sodium, Tween T-601%, 2-acrylamido-2-methyl-propane Sulfonic acid 0.5%), initiator (potassium persulfate) 0.2%, pH regulator (ammonia) 0.5%, reducing agent (acetophenazine) 0.5%, buffer (sodium bicarbonate) 0.3%, wetting Agent (104E, product of Gas Chemical Company) 0.5%, water-based defoamer (DC-65, product of Dow Corning) 0.2%, water-based preservative (MB-16, product of Haimingsi) 0.1% and the balance 36.2% Deionized water.

[0135] (2) Component B (foam rubber): 0.8% adhesion promoter (Z-6040, Dow Corning company product), 0.5% wetting and dispersing agent (104E, gas chemical company product),...

Embodiment 2

[0143] 1. Formula: Take 100 parts of component A main emulsion resin, and 51.1 parts of component B styrofoam.

[0144] among them,

[0145] (1) Component A (main emulsion resin): styrene 10%, butyl acrylate 22%, isooctyl acrylate 18%, methyl methacrylate 5%, 2-hydroxyethyl methacrylate 1%, Acrylic acid 0.5%, diacetone acrylamide 1%, acrylamide 0.5%, emulsifier (sodium hydroxypropane methacrylate 0.5%, Tween T-601%, 2-acrylamido-2-methyl-propyl Sulfonic acid 0.5%), initiator (potassium persulfate) 0.2%, pH regulator (ammonia) 0.5%, reducing agent (acetophenazine) 0.5%, buffer (sodium bicarbonate) 0.3%, wetting agent (104E, Gas Chemical Company product) 0.5%, water-based defoamer (DC-65, Dow Corning product) 0.2%, water-based preservative (MB-16, Haimingsi product): 0.1% and the balance 37.7% Deionized water.

[0146] (2) Component B (foam rubber): 0.8% adhesion promoter (Z-6040, Dow Corning company product), 0.5% wetting and dispersing agent (104E, gas chemical company product), 0...

Embodiment 3

[0154] 1. Formula: Take 100 parts of component A main emulsion resin and 49.8 parts of component B foam rubber, of which,

[0155] (1) Component A (main emulsion resin): styrene 8%, butyl acrylate 25%, isooctyl acrylate 15%, methyl methacrylate 8%, 2-hydroxyethyl methacrylate 1%, Acrylic acid 1%, diacetone acrylamide 1%, acrylamide 0.5%, emulsifier (from 0.5% hydroxypropane methacrylate sodium, Tween T-601%, 2-acrylamido-2-methyl-propane Sulfonic acid 0.5%), initiator (potassium persulfate) 0.2%, pH regulator (ammonia) 0.5%, reducing agent (acetophenazine) 0.5%, buffer (sodium bicarbonate) 0.3%, wetting Agent (104E, product of Gas Chemical Company) 0.5%, water-based defoamer (DC-65, product of Dow Corning) 0.2%, water-based preservative (MB-16, product of Haimingsi): 0.1% and balance 36.2% Deionized water.

[0156] (2) Component B (foam rubber): 0.5% adhesion promoter (Z-6040, Dow Corning product), 0.5% wetting and dispersing agent (104E, gas chemical company product), 0.2% water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com