A method for co-deposition of aluminum sol and metal nickel ions

A technology of metal nickel and aluminum sol, applied in the direction of electrolytic paint, coating, etc., can solve the problems of reducing the plating temperature and low brightness of the coating, and achieve the effect of reducing the plating temperature and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step, pre-treatment: workpiece grinding (sandpaper grinding can be used), non-working surface insulation (insulating tape can be used), chemical degreasing of the working surface, hot water washing (50 ℃ hot water), running tap water washing, pickling, Wash under running tap water. The workpiece is QT450-10 ductile iron workpiece.

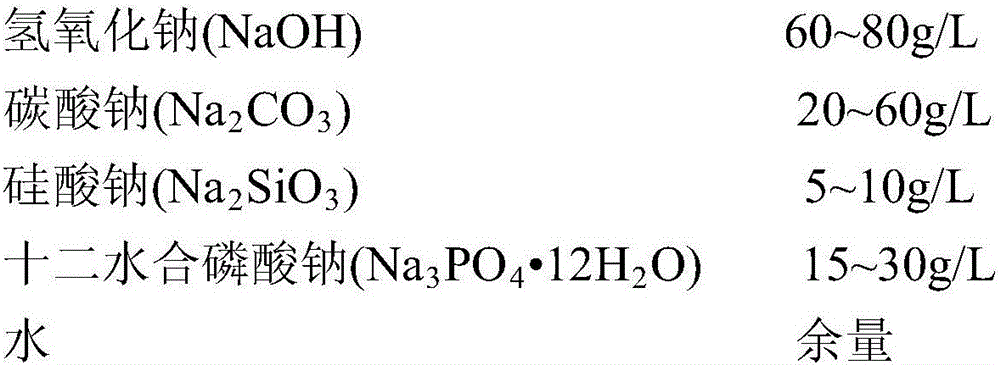

[0025] In this experiment, chemical degreasing was used, and the composition of the degreasing liquid was:

[0026]

[0027] The continuous water film on the working surface of the workpiece substrate means that the oil on the working surface has been removed.

[0028] 5% industrial hydrochloric acid is used for pickling, and a commercially available acid mist inhibitor is added to the industrial hydrochloric acid, so that the concentration of the commercially available acid mist inhibitor in the mixture of industrial hydrochloric acid and commercially available acid mist inhibitor is 1mL / L.

[0029] The second step is electro...

Embodiment 2

[0037] A method for co-deposition of aluminum sol and metallic nickel ions, comprising the following steps:

[0038] The first step, pre-treatment: workpiece grinding (sandpaper grinding can be used), non-working surface insulation (insulating paint can be applied), working surface chemical degreasing, hot water washing (70 ℃ hot water), running tap water washing, pickling, flow Wash with running water. The workpiece is a Q235 steel workpiece.

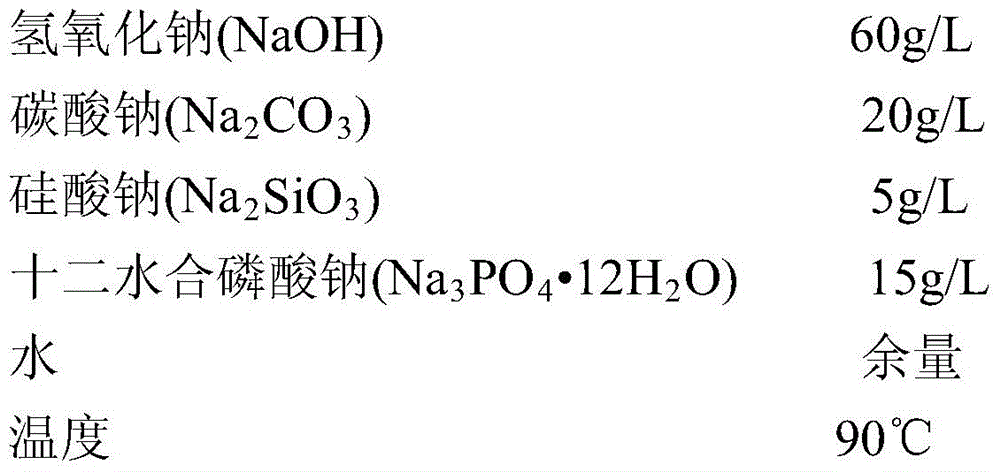

[0039] In this experiment, chemical degreasing was used, and the composition of the degreasing liquid was:

[0040]

[0041] The continuous water film on the working surface of the workpiece base means that the oil on the working surface of the workpiece has been removed.

[0042] 20% industrial hydrochloric acid is used for pickling, and a commercially available acid mist inhibitor is added to the industrial hydrochloric acid, so that the concentration of the commercially available acid mist inhibitor in the mixture of industrial...

Embodiment 3

[0051] The first step, pre-treatment: workpiece grinding (sandpaper grinding can be used), non-working surface insulation (wrapped with insulating tape), chemical degreasing of the working surface, hot water washing (60 ℃ hot water), running tap water washing, pickling, running tap water wash. Described workpiece is 45# steel workpiece.

[0052] In this experiment, chemical degreasing was used, and the composition of the degreasing liquid was:

[0053]

[0054] The continuous water film on the working surface of the workpiece base means that the oil on the working surface of the workpiece has been removed.

[0055]Pickling uses 15% industrial hydrochloric acid, and commercially available acid mist inhibitors are added to industrial hydrochloric acid, so that the concentration of commercially available acid mist inhibitors in the mixture of industrial hydrochloric acid and commercially available acid mist inhibitors is 12mL / L.

[0056] The second step is electroplating-ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com