Optical fiber measurement method and device of blade tip clearance

A technology of optical fiber measurement and blade tip clearance, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor measurement accuracy, large measurement errors, interference of blade tip radiation spectrum, etc., and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention can measure the tip clearance of the high-speed rotating blade at high temperature, has the function of compensating the small inclination angle of the measured surface, and provides detailed and reliable data for the active control of the tip clearance of the ground gas turbine or aeroengine.

[0043] The technical solution of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

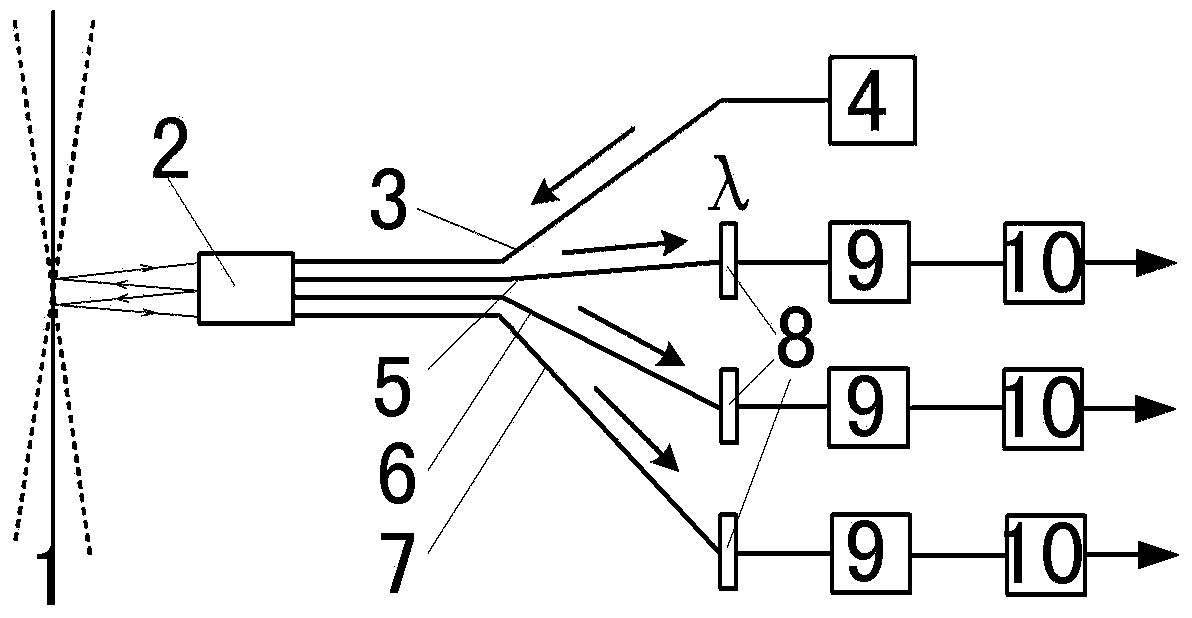

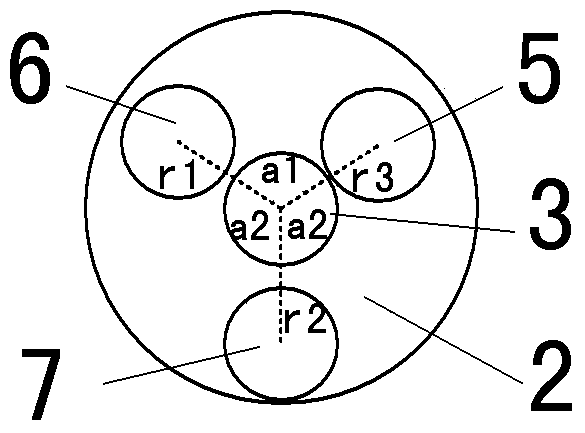

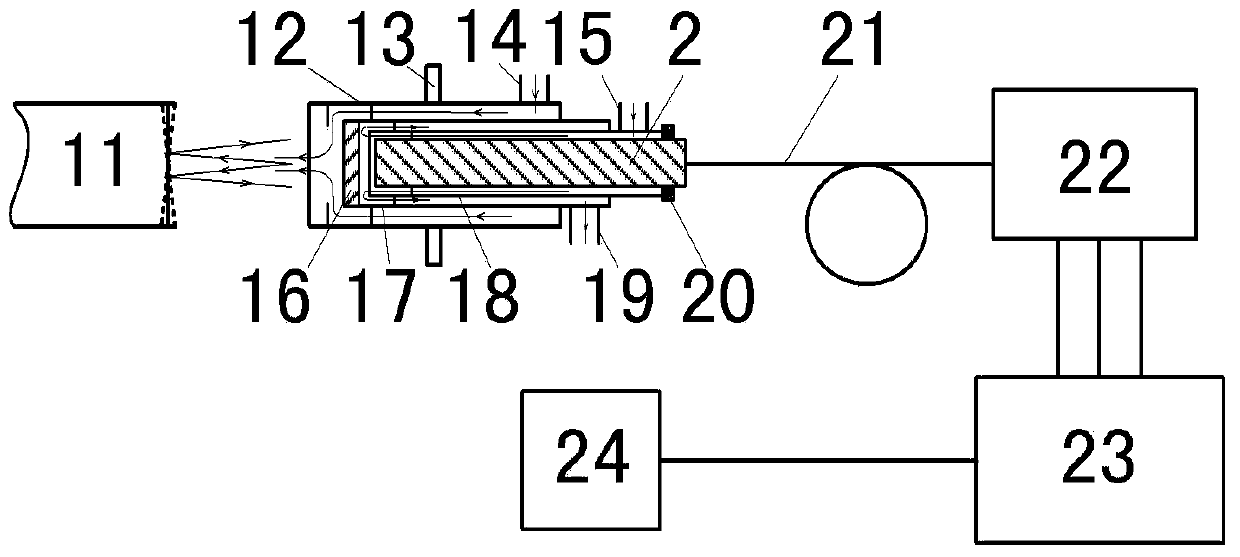

[0044] Please combine Figure 1-Figure 3 .

[0045] figure 1 It is the principle diagram of the multi-point positioning reflection compensation type optical fiber ranging of the present invention (this embodiment takes three as examples), the self-temperature-controlling laser 4 emits a laser with a certain working wavelength in the working band between 300-450nm, and the coupling Enter the transmitting optical fiber 3, transmit to the measured surface 1 through the optical fiber probe 2, return to the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com