Thermal compensation design method for high-temperature air pipeline

A design method and high-temperature air technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of increasing the weight of the pipeline, affecting the life of the pipeline, and failing to meet the requirements of the engine, so as to improve the rationality and high reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

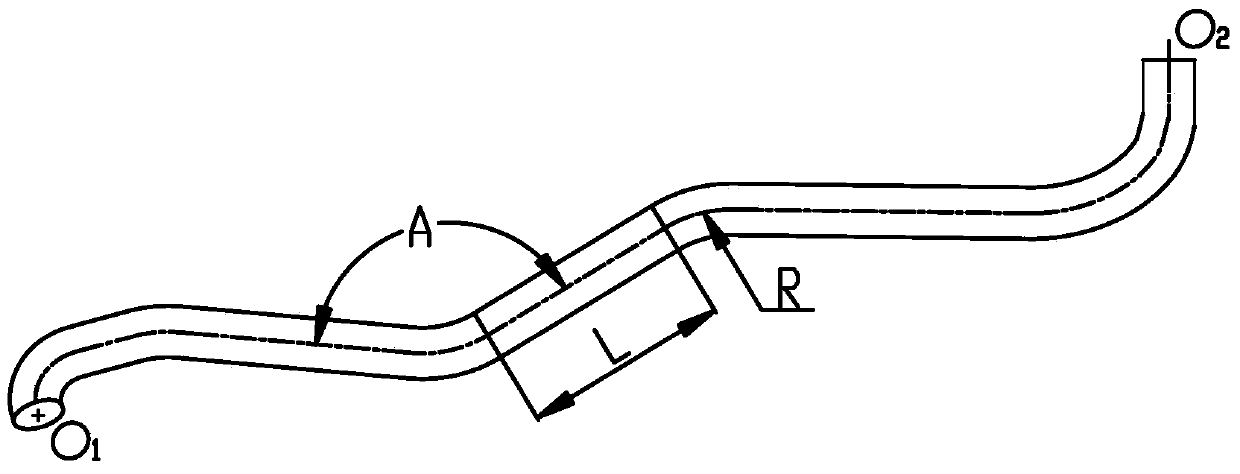

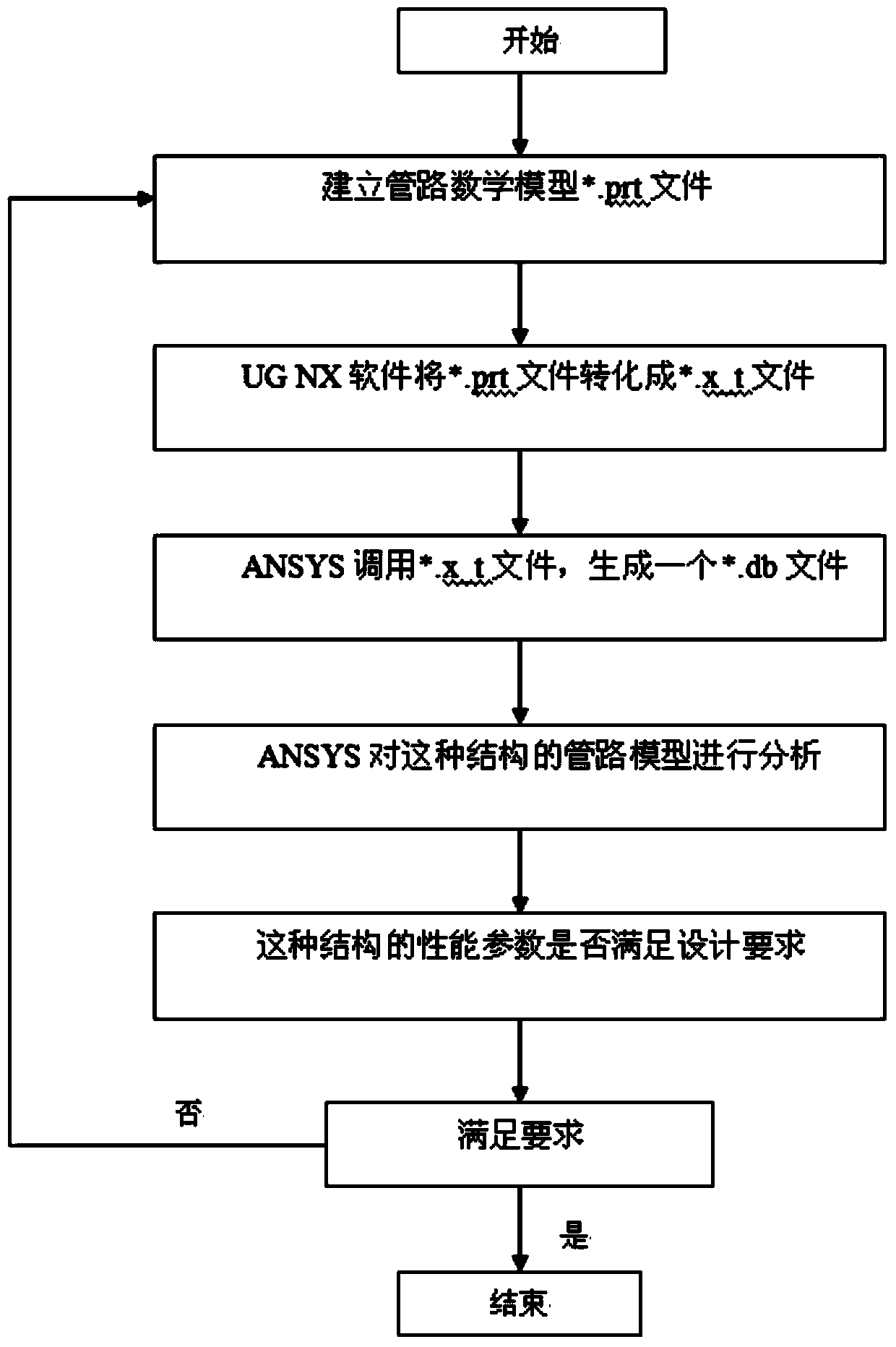

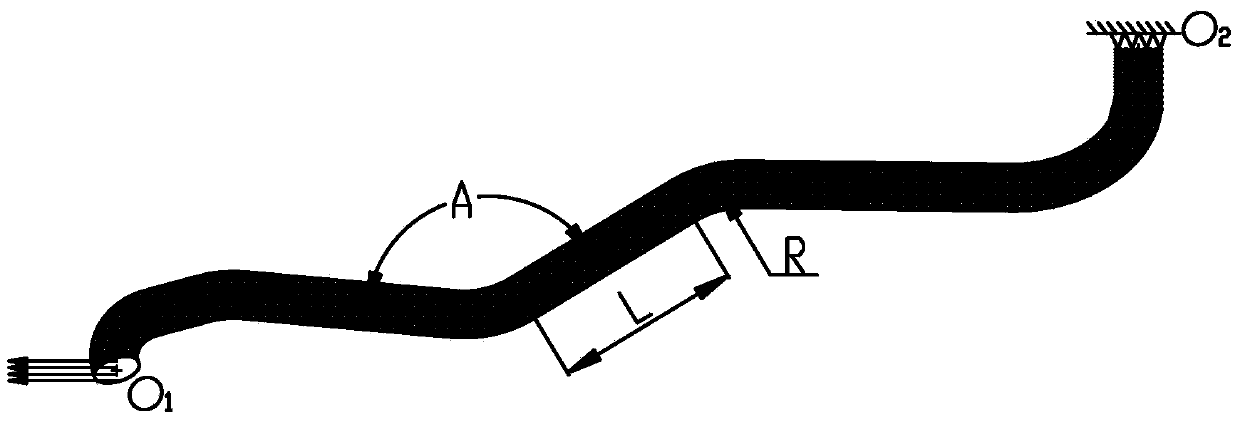

[0036] The invention provides a thermal compensation design method for high-temperature air pipelines, which is characterized in that: the thermal compensation design method for high-temperature air pipelines uses UG NX commercial software under its mechanical pipeline layout module to establish a system containing 7 piping geometry model of mathematical variables (see figure 1 ), save it as a *.prt format file; see Table 1 for the definition of each mathematical variable;

[0037]

[0038]

[0039] Use the format conversion function of UG NX software to generate *.x_t format files;

[0040] Use the finite element analysis software ANSYS to call *.x_t files to generate *.db format files;

[0041] The *.db format file is read by the finite element analysis software ANSYS, and the pre-processing is carried out. The material parameters are given according to GH536, where the elastic modulus E=187GPa, Poisson’s ratio μ=0.3, and the linear expansion coefficient is shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com