Sodium secondary cell electrode and sodium secondary cell

A sodium secondary battery and electrode technology, applied in the field of sodium secondary battery electrodes and sodium secondary batteries, can solve problems such as worry, and achieve the effect of suppressing the reduction of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] As the solvent used in the preparation of the electrode mixture paste, for example, in addition to water, aprotic polar solvents such as N-methylpyrrolidone; alcohols such as isopropanol, ethanol, and methanol; propylene glycol dimethyl ether, etc. Ethers; ketones such as acetone, methyl ethyl ketone, methyl isobutyl ketone, etc. In the case where the binder increases the viscosity, a plasticizer may also be used for ease of coating on the current collector.

[0086] There is no particular limitation on the method of coating the electrode mixture paste on the current collector. For example, methods such as a slot die coating method, a screen coating method, a curtain coating method, a knife coating method, a gravure coating method, and an electrostatic spraying method are mentioned. In addition, as drying performed after coating, heat treatment may be performed, and blast drying, vacuum drying, or the like may be performed. In the case of drying by heat treatment, the...

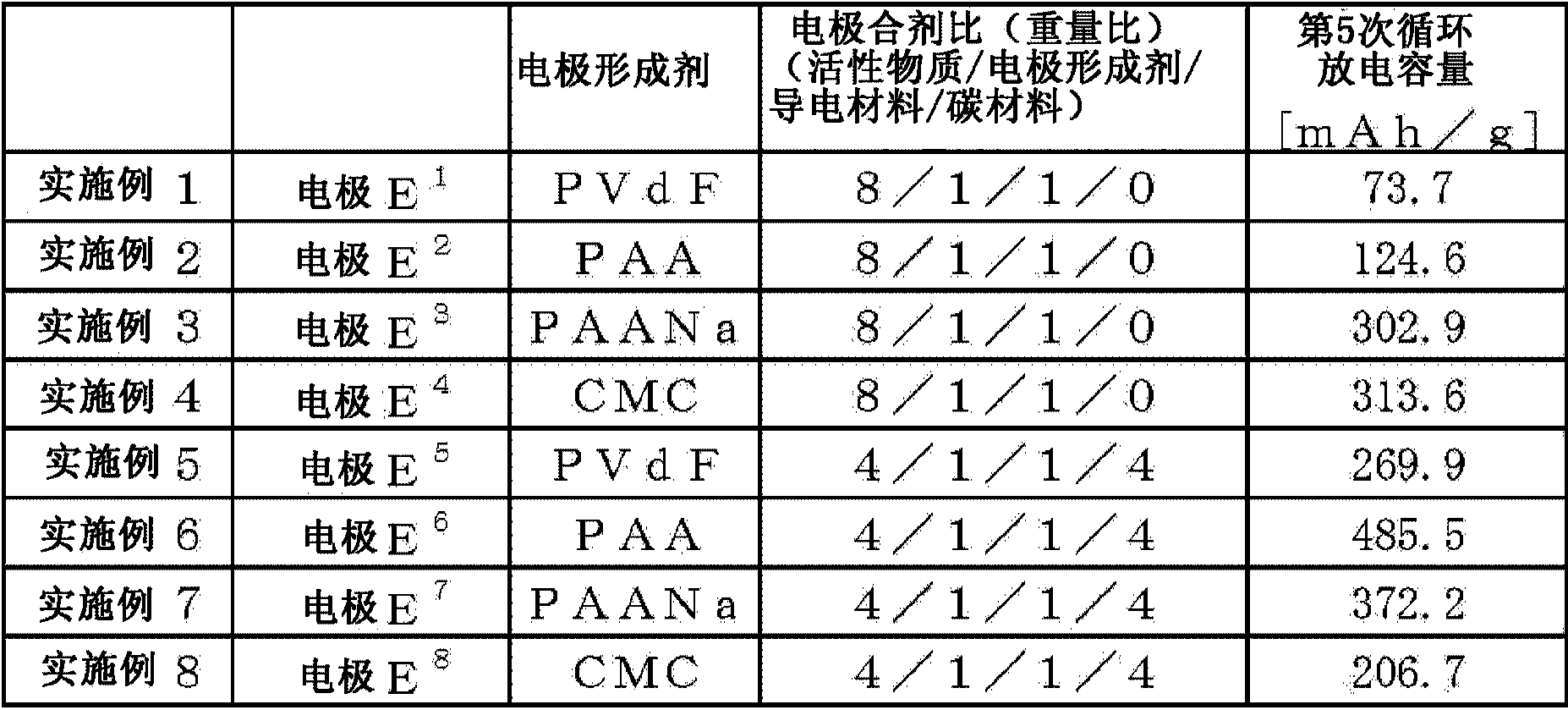

Embodiment 1

[0161] (Na secondary battery electrode E 1 manufacturing)

[0162] Sn powder (manufactured by Aldrich Corporation (particle size: 150 nm, purity: 99.7%) , acetylene black (manufactured by Denki Kagaku Kogyo Co., Ltd.) as a conductive material, and polyvinylidene fluoride (PVdF: manufactured by KUREHA Co., Ltd., #1300) as an electrode-forming agent. First, the electrode-forming agent was added to an agate mortar, and Among them, an appropriate amount of N-methyl-2-pyrrolidone (NMP: manufactured by Tokyo Chemical Industry Co., Ltd.) was added as a solvent and mixed thoroughly. After confirming that the electrode forming agent was dissolved, an electrode active material and a conductive material were added and mixed thoroughly. This results in an electrode mixture paste. Apply the resulting electrode mixture paste on a copper foil with a thickness of 100 μm using a dispenser, put it in a dryer, and dry it sufficiently while removing the solvent to obtain Electrode sheet. After ...

Embodiment 2

[0164] (Na secondary battery electrode E 2 manufacturing)

[0165] Except that polyacrylic acid (PAA: manufactured by Sigma Aldrich, molecular weight 750,000) was used as an electrode forming agent instead of PVdF, and ion-exchanged water was used as a solvent, the sodium secondary battery electrode E was obtained by the same operation as in Example 1. 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com