Semi-solid battery positive electrode material and alkaline zinc-manganese battery prepared from same

A battery positive electrode, zinc-manganese battery technology, applied in the direction of electrode manufacturing, battery electrodes, primary battery use/maintenance, etc., can solve the problem of unsatisfactory storage performance of alkaline manganese batteries, failure to improve high-current discharge performance, and improvement of battery discharge performance limited problems, to achieve the effects of reducing the positive polarization effect, stabilizing the photoelectrochemical properties, and improving the discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The semi-solid battery cathode material of Example 1 comprises the following components in parts by weight:

[0040] Electrolytic manganese dioxide (EMD): 170 parts

[0041] TiO(OH) 2 : 0.2 parts

[0042] Flake graphite: 15 parts

[0043] Zinc stearate: 0.18 parts

[0044] Electrolyte: 95 parts

[0045] The negative electrode material comprises the following components in parts by weight:

[0047] Sodium polyacrylate / polyacrylic acid (2:1, w / w): 1.1 parts

[0048] Indium oxide: 0.04 parts

[0049] Electrolyte: 52 parts

[0050] Pure water: 4.5 parts

[0051] Wherein, the electrolytic solution is an aqueous potassium hydroxide solution with a content of 35% (w / w).

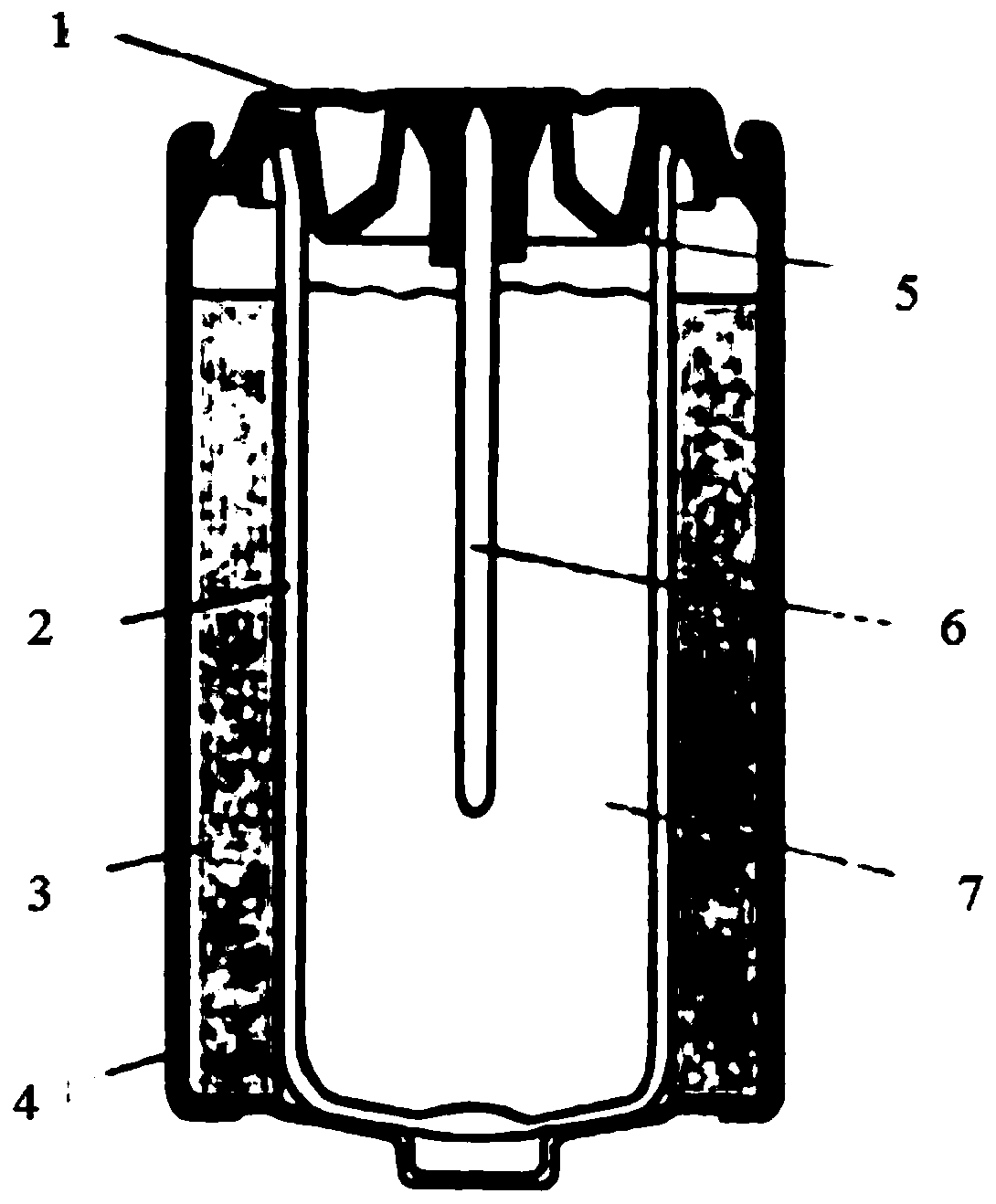

[0052] refer to figure 1 , figure 1 It is the structural representation of the alkaline zinc-manganese battery of the present embodiment 1, and its preparation method is as follows:

[0053] S1. Preparation of coated steel shell: Mix the conductive agent carbon bla...

Embodiment 2

[0058] The positive electrode material and negative electrode material formula of the semi-solid battery in Example 2 are the same as in Example 1. The difference between the preparation method of the semi-solid alkaline zinc-manganese battery and Example 1 is that the battery model is LR14. In the battery assembly step, the positive electrode The injection amount of the material is about 30g, the injection amount of the negative electrode material is about 20g, and other preparation processes are the same as in Example 1.

Embodiment 3

[0060] The only difference between Example 3 and Example 1 is that the gelling agent is sodium polyacrylate: 1.1 parts.

[0061] The preparation method of the alkaline zinc-manganese battery of embodiment 3 is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com