Enteral nutrition preparation capable of protecting intestinal mucosal barrier function injured by chemotherapy

A technology for nutritional preparations and chemotherapy damage, applied in food preparation, food science, applications, etc., can solve problems such as exacerbated immune function, mucosal barrier dysfunction, and increased permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

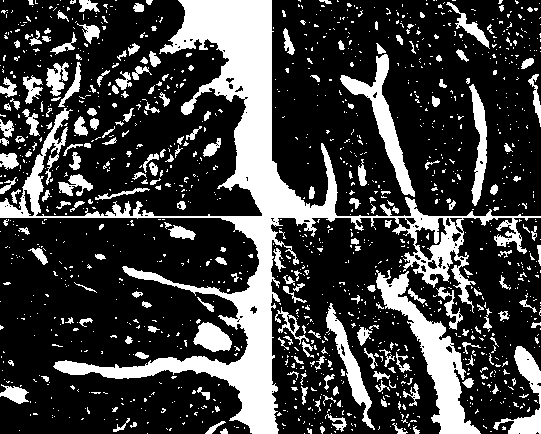

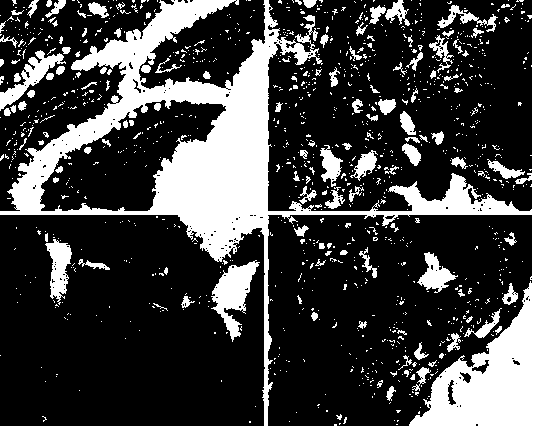

Image

Examples

Embodiment 1

[0084] Example 1 Preparation of oyster polysaccharide

[0085] Shell the oysters and take the meat, wash and drain with distilled water, homogenate, add 4 times the volume of distilled water, and use ultrasonic pretreatment, the ultrasonic power is 800W, the temperature is 60°C, the ultrasonic time is 30min, and the ultrasonic time / intermittent time is 3 / 5 (s / s), then placed in a water bath shaking pot preheated to 55°C, adjusted the pH value to 8.0, added alkaline protease 3000U / g, after 4 hours of enzymolysis, inactivated the enzyme in a water bath at 100°C for 10 minutes, centrifuged at 1800 × g, Take the supernatant for 15 minutes, concentrate in vacuo, add absolute ethanol to adjust the ethanol content of the system to 30%, leave it at 4°C for 24 hours, and centrifuge to take the supernatant, add absolute ethanol to adjust the system ethanol degree to 60%, 4°C Stand still for 24 hours and centrifuge to take the precipitate, dry it in vacuum and grind it into powder, wh...

Embodiment 2

[0087] Example 2 Preparation of oyster polysaccharide

[0088] Shell the oysters and take the meat, wash and drain with distilled water, homogenate, add 6 times the volume of distilled water, use ultrasonic pretreatment, ultrasonic power is 900W, temperature is 50°C, ultrasonic time is 20min, ultrasonic time / intermittent time is 3 / 5 (s / s), then placed in a water bath shaking pot preheated to 45°C, adjusted the pH value to 8.0, added trypsin 3000U / g, after 6 hours of enzymolysis, inactivated the enzyme in a water bath at 100°C for 10 minutes, centrifuged at 1800 × g, 15 Take the supernatant in 1 min, concentrate in vacuo, add absolute ethanol to adjust the ethanol content of the system to 30%, leave it at 4°C for 24 hours, centrifuge to take the supernatant, add absolute ethanol to adjust the system ethanol degree to 60%, and stand at 4°C Centrifuge for 24 hours to take the precipitate, dry it in vacuum and grind it into powder, which is the oyster polysaccharide component s...

Embodiment 3

[0090] Example 3 Preparation of enteral nutrition powder

[0091] Fresh oysters are shelled to take the meat, washed with distilled water, drained, homogenized, added with 6 times the volume of distilled water, and pretreated with ultrasonic waves. The ultrasonic power is 800W, the temperature is 60°C, the ultrasonic time is 30min, and the ultrasonic time / interval time is 3 / 5 (s / s), then placed in a water bath shaking pot preheated to 55°C, adjusted the pH value to 8.0, added alkaline protease 3000U / g, enzymatically hydrolyzed for 4h, inactivated the enzyme in a water bath at 100°C for 10min, and centrifuged at 1800 × g , 15 minutes to take the supernatant, vacuum concentration to 15% solid content, keep warm in 50 ℃ water bath, add premixed olive oil, fish oil and medium chain triglycerides while stirring, then add maltodextrin 10% , stirring and dissolving homogeneously until the material liquid is uniform without oil droplets, spray drying to make powder, the conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com